Bottom surface crack detection device for concrete bridge

A detection device and concrete technology, which is applied in the direction of optical testing for flaws/defects, etc., can solve problems such as difficulty in ensuring the quality of collected images, limited scope of application, and low precision of cracks, and achieve reliable performance, simple and fast installation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention is further described in combination with the following examples.

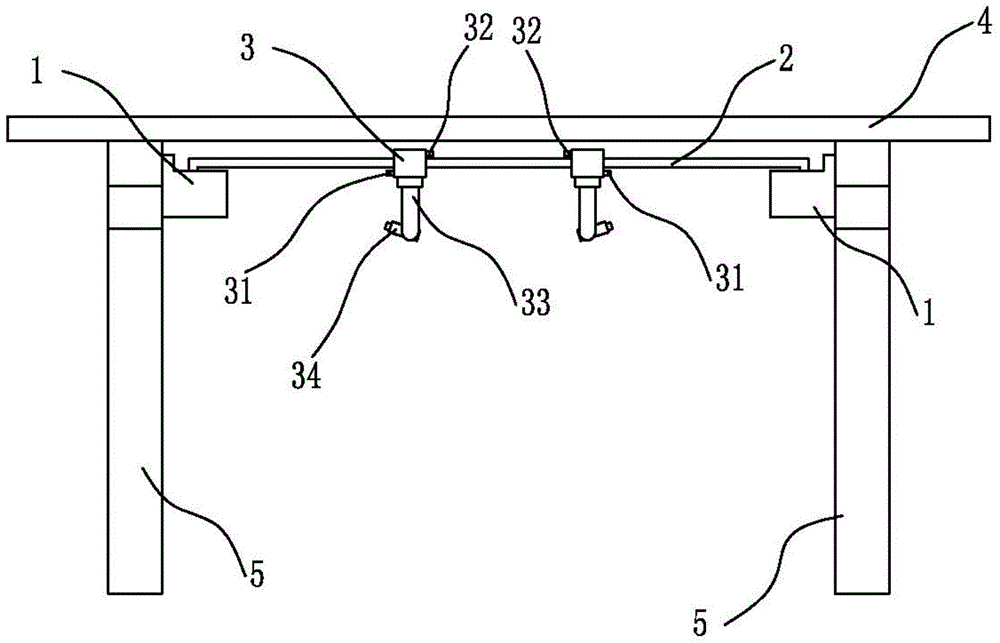

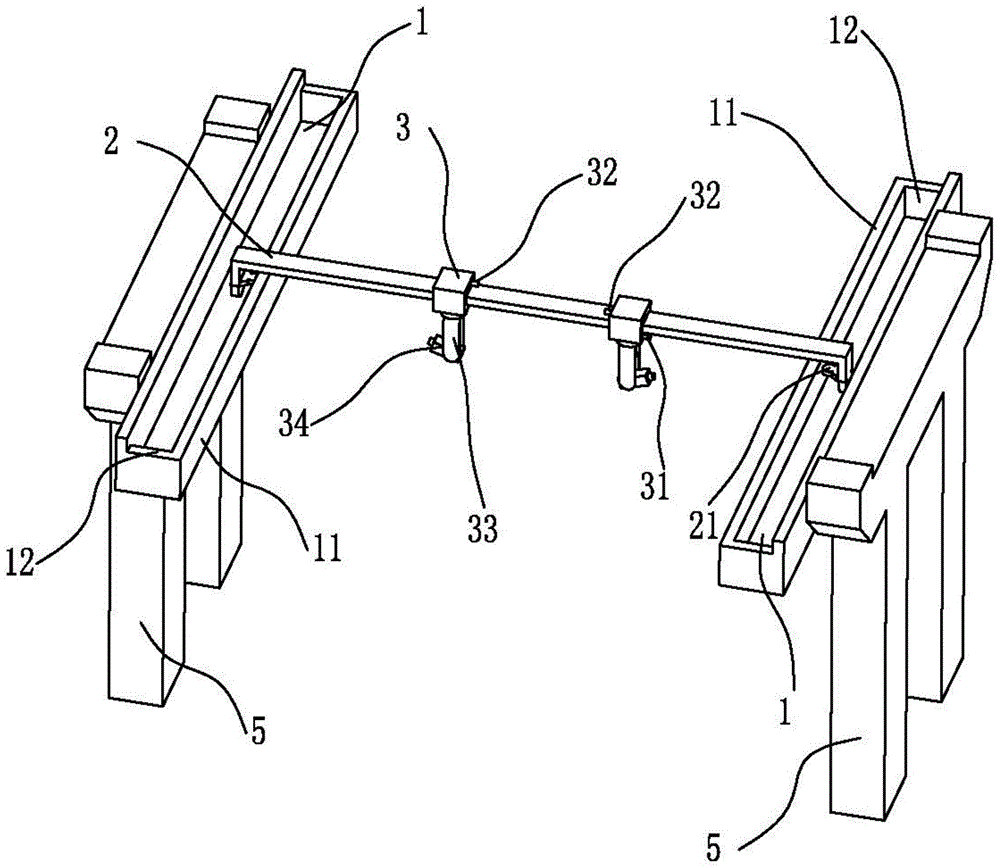

[0022] The invention creates a device for detecting cracks on the bottom surface of a concrete bridge, such as figure 1 with figure 2 As shown, it includes two parallel rail brackets 1, one rail 2, two camera equipment 3, wireless transmission equipment and monitoring equipment.

[0023] reference figure 1 with figure 2 , Two guide rail brackets are arranged between two adjacent bridge piers 4, transversely parallel to the bottom surface of the bridge. The guide rail 2 is vertically arranged between the two guide rail supports 1 and can move along the guide rail support 1. Both ends of the guide rail support 1 are provided with limit parts 12 to restrict the guide rail 2 and prevent it from going out of the guide rail support 1 during the movement. . Preferably, the guide rail bracket 1 extends to the outside of the bridge 4 and exceeds the edge of the bridge 4 for a short period of time to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com