Mask plate and method for reducing splicing exposure mula phenomenon

A mask plate and mask plate technology, applied in the field of photolithography, can solve problems such as splicing exposure mura, exposure alignment error, and complex manufacturing process of TFT array substrates, so as to reduce the difference in display brightness, improve picture quality, and eliminate shadowing. pull effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

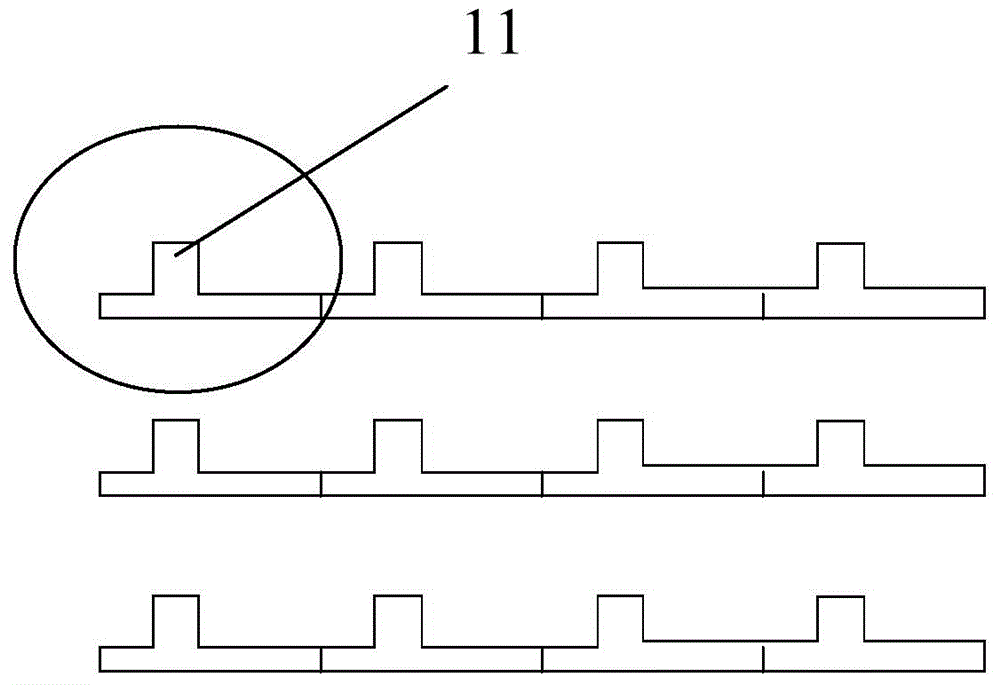

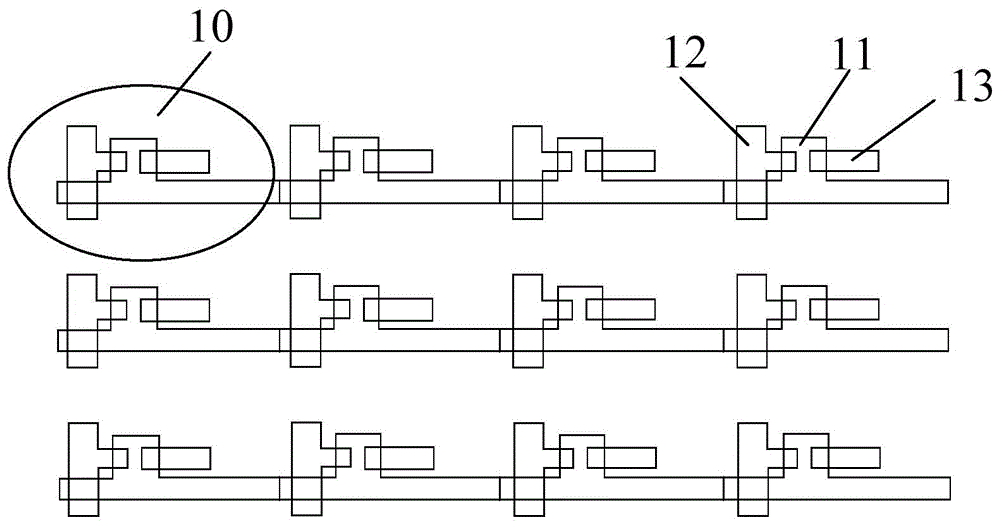

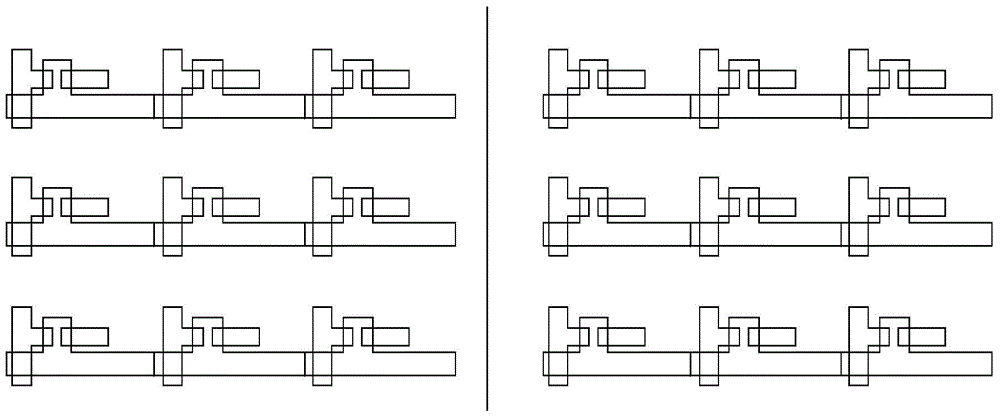

[0027] A mask plate provided by an embodiment of the present invention is applied to fabricate an array substrate by splicing exposure, and the array substrate includes a plurality of pattern areas and splicing areas between adjacent pattern areas; it is characterized in that, The mask plate includes: a plurality of complete transmission regions and partial transmission regions between adjacent complete transmission regions; wherein, the complete transmission regions correspond to pattern regions on the array substrate, and the partial transmission regions The area corresponds to the splicing area on the array substrate, and the width of the partial transmission area is greater than the width of the splicing area.

[0028] Here, the width of the partial transmission area is the sum of the width of the stitching area and twice the alignment accuracy between the mask plate and the array substrate.

[0029] Here, the exposure rate of the partially transmissive region is n / n, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com