Practical training table for automobile assembling

A technology for automobile assembly and training platform, which is applied to educational appliances, instruments, teaching models, etc., can solve the problems of a large number of training equipment, high procurement costs, and low training efficiency, so as to improve training efficiency and reduce training costs. , Improve the effect of site utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

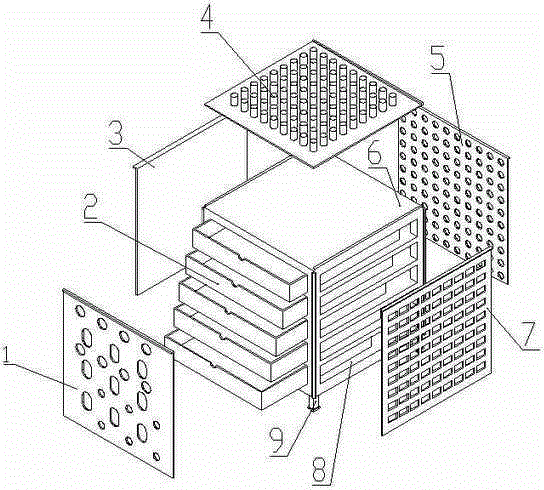

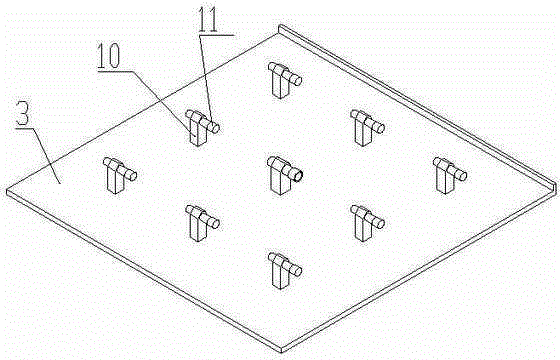

[0009] The specific content of the present invention will be described in detail in conjunction with the accompanying drawings. An automobile assembly training platform, which is mainly composed of a base frame 6, a training board and a storage box 2, the inside of the base frame 6 is provided with a storage partition layer 8 with openings around the vertical direction, and the storage boxes 2 are respectively slidable on the In the storage division layer 8, training parts or tools required for training are respectively placed in the storage box 2, and the support rods of the base frame 6 are respectively provided with vertical draw-in grooves 12 parallel to the plane adjacent to the support frame. , the vertical slots 12 are respectively provided with training boards slidingly matched with the vertical slots 12, and the upper side of the base frame 6 is provided with a pair of parallel horizontal slide slots 13, and the horizontal slide slots 13 are provided with horizontal sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com