Teaching tool for testing faults of power cable

A fault testing and power cable technology, applied in the field of teaching tools, can solve problems such as difficulty in waveform identification, complex training process, non-standard waveforms, etc., and achieve the effects of improving stability and versatility, improving training effects, and accurate fault resistance values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

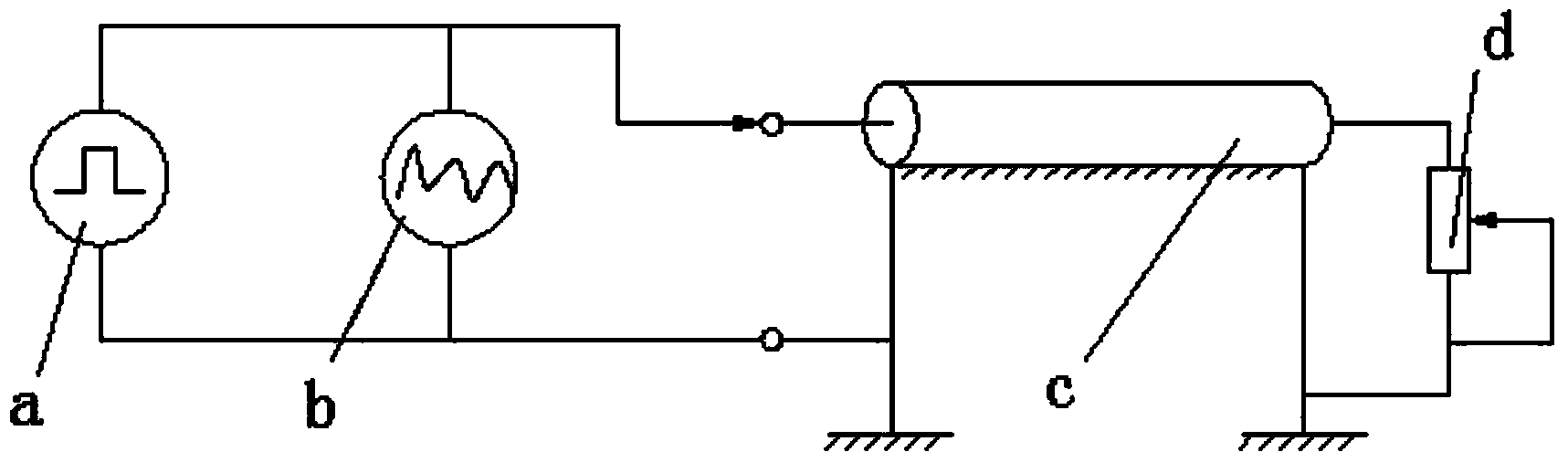

[0026] figure 1 It is the schematic diagram of the teaching tool, the power cable fault test teaching tool, including the upper computer b, the fault tester a, and the rheostat d composed of a notebook computer, the upper computer b is connected with the fault tester a, and the fault tester a performs waveform data Acquisition, processing, and communication with the upper computer b to send the waveform data to the upper computer b for display; the fault tester a is connected to the rheostat d through the communication coaxial cable c, and the fault setting is performed by adjusting the resistance value of the rheostat d to simulate a cable fault .

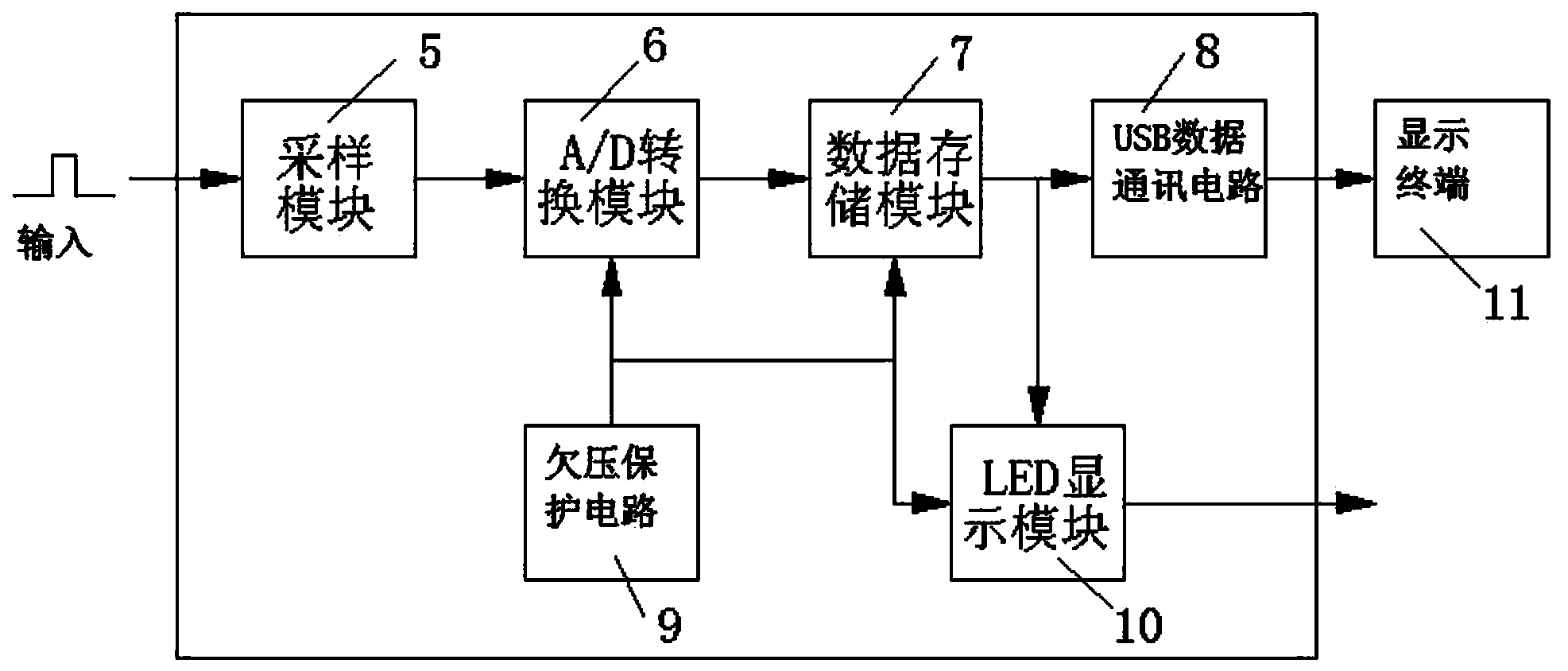

[0027] like figure 2 As shown, the fault tester includes a single-chip microcomputer, an acquisition module 5, an A / D conversion module 6, a data storage module 7 and a USB data commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com