Industrial coal boiler energy-saving operation skill simulation training device and method

A technology of energy-saving operation and coal-fired boilers, which is applied to the simulation devices of space navigation conditions, transportation and packaging, instruments, etc., can solve the problems of lack of excess air coefficient, exhaust gas temperature boilers, and no chain grate, etc., to reduce training Cost, real sense of operation, and highly targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

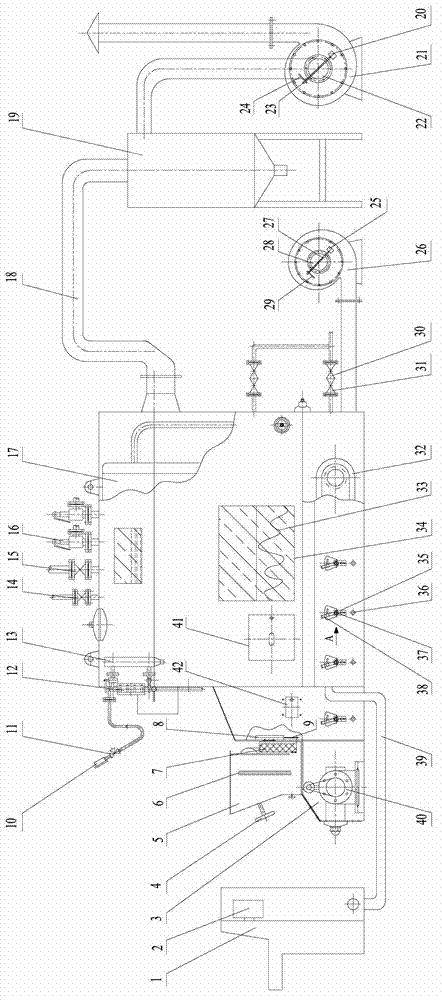

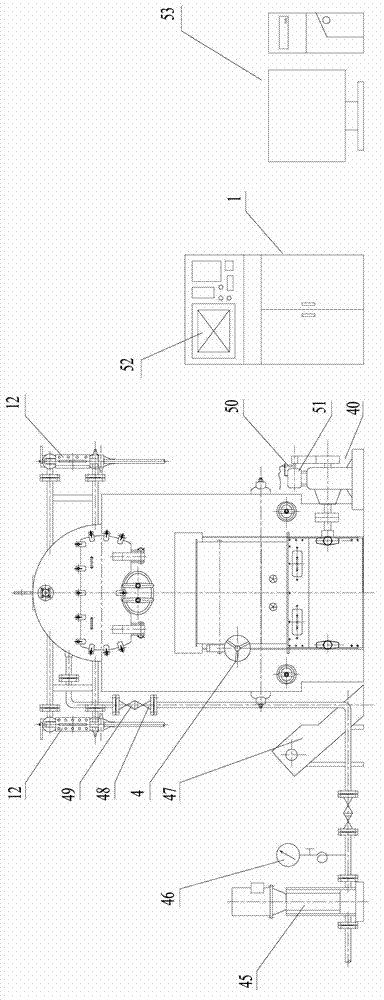

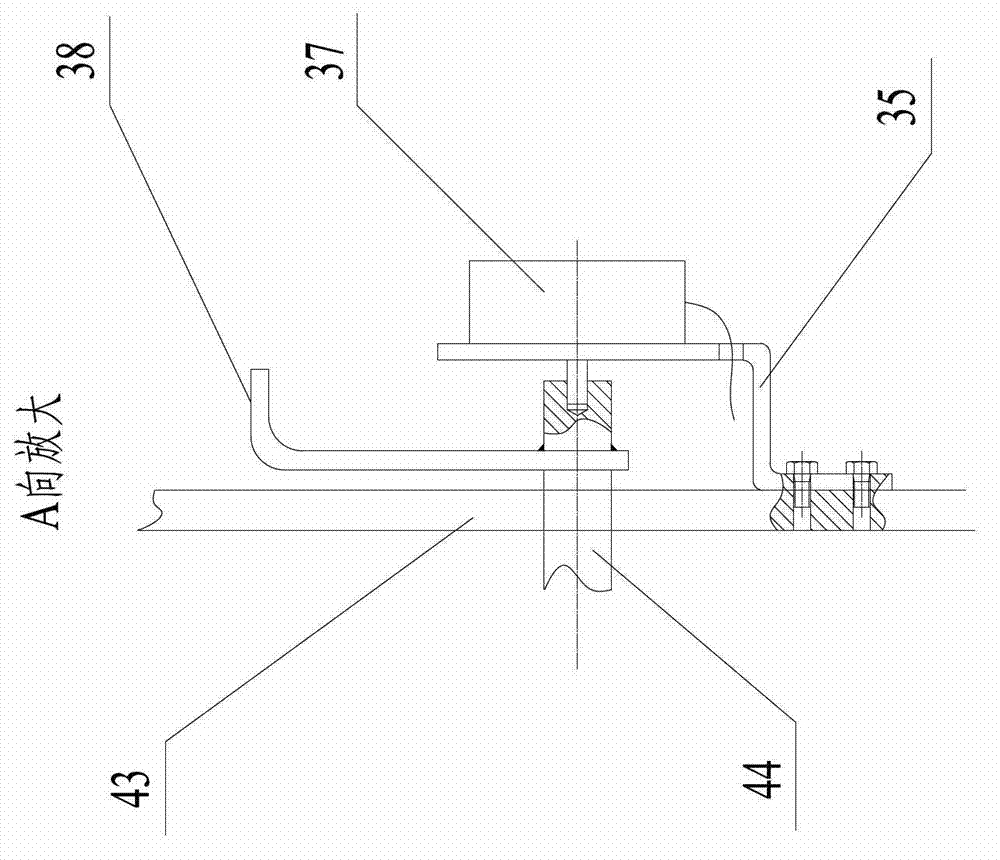

[0029] like figure 1 , figure 2 As shown, the industrial coal-fired boiler energy-saving operation skill simulation training device of the present invention is composed of three parts: the boiler entity physical model, the operation console 1, and the simulation microcomputer 53. The physical physical model of the boiler is composed of the chain grate 3, the drum 17 and its outsourcing structure, the valves and instruments installed on the drum, and the supporting auxiliary equipment of the boiler. The chain grate 3 includes a grate base, a coal hopper 5, and a grate driving device 40. A fire viewing window 42, 4 segmented dampers and 4 ash cleaning rods 36 are arranged on the grate base; Structurally, there are a fire door 41 and a furnace viewing window 34; the valves installed on the drum include a safety valve 16, a main steam valve 15, an exhaust valve 14, a qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com