Device for simulating microgravity environment object carrying training and friction torque compensation method thereof

A technology for simulating microgravity and friction, which is applied in the simulation devices of space navigation conditions, transportation and packaging, and space navigation equipment. , the effect of efficient training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

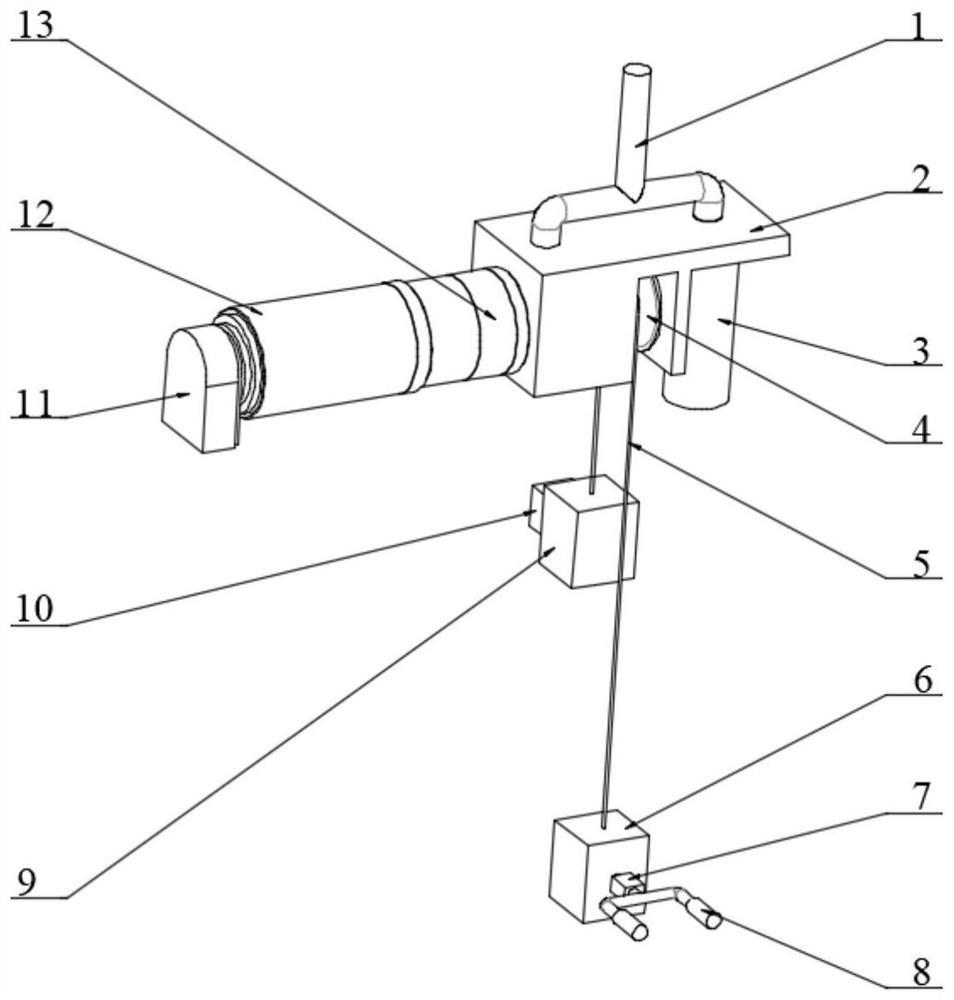

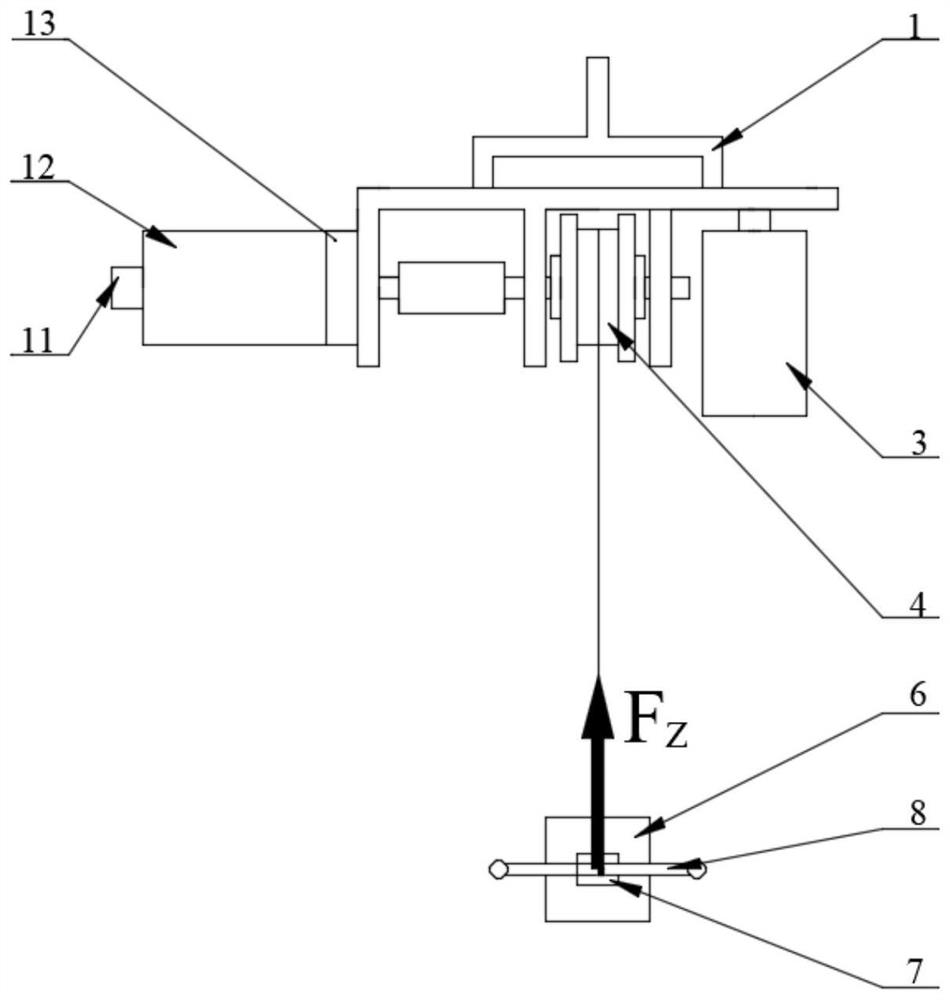

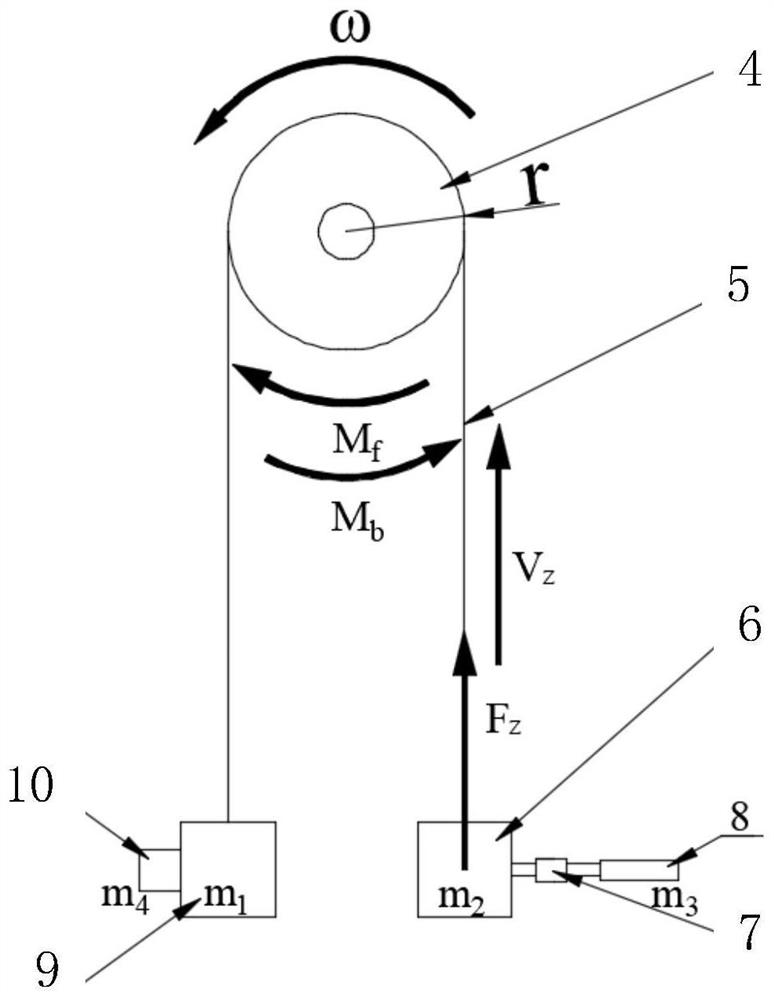

[0016] combine Figure 1 to Figure 5 , a kind of simulated microgravity environment carrying training device of the present invention (hereinafter referred to as " training device "), comprise the main support rod 1 that is used to suspend training device, be used to install the pulley platform 2 of friction compensating motor and pulley, pulley Platform counterweight 3, pulley 4, wire rope 5, simulated load 6, multi-dimensional force sensor 7, handle 8, simulated load counterweight 9, handle counterweight 10, encoder 11, friction compensation motor 12, motor brake 13 . The main support bar on the pulley platform bears all the gravity (all mass) of the training device. After the power is turned on, the friction compensation motor is in working condition to offset the friction torque generated by the pulley shaft and supporting bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com