Removal tool for electrical plug contacts

A technology for disassembling tools and contacts, applied in the assembly/disassembly of contacts, electrical components, manufacturing tools, etc., can solve problems such as damage to guide surfaces, damage to locking components, etc., to reduce scrap rate, compensate for plug errors, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Among the reference numerals used in the drawings, elements having the same function have the same reference numerals.

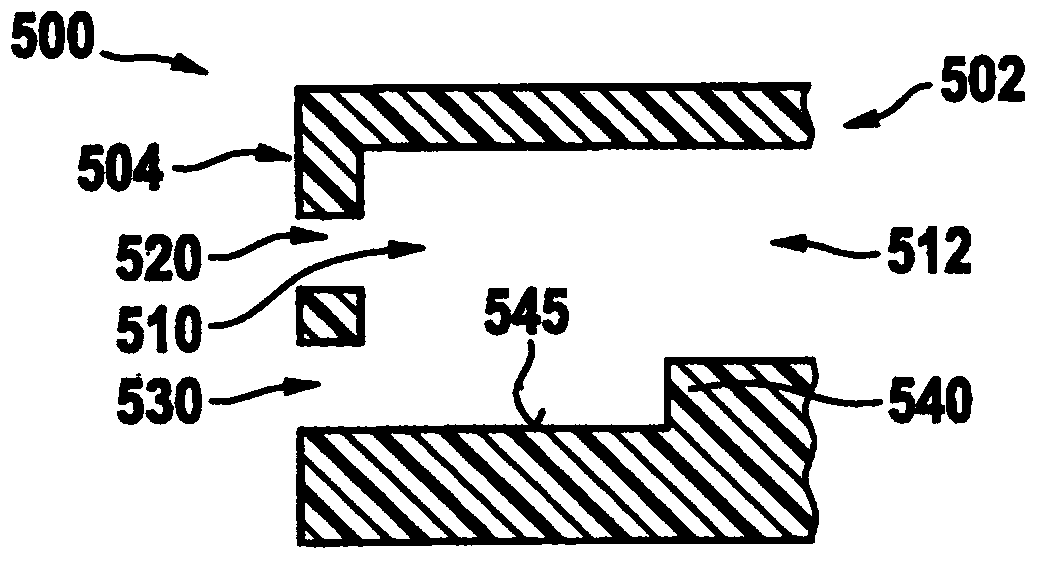

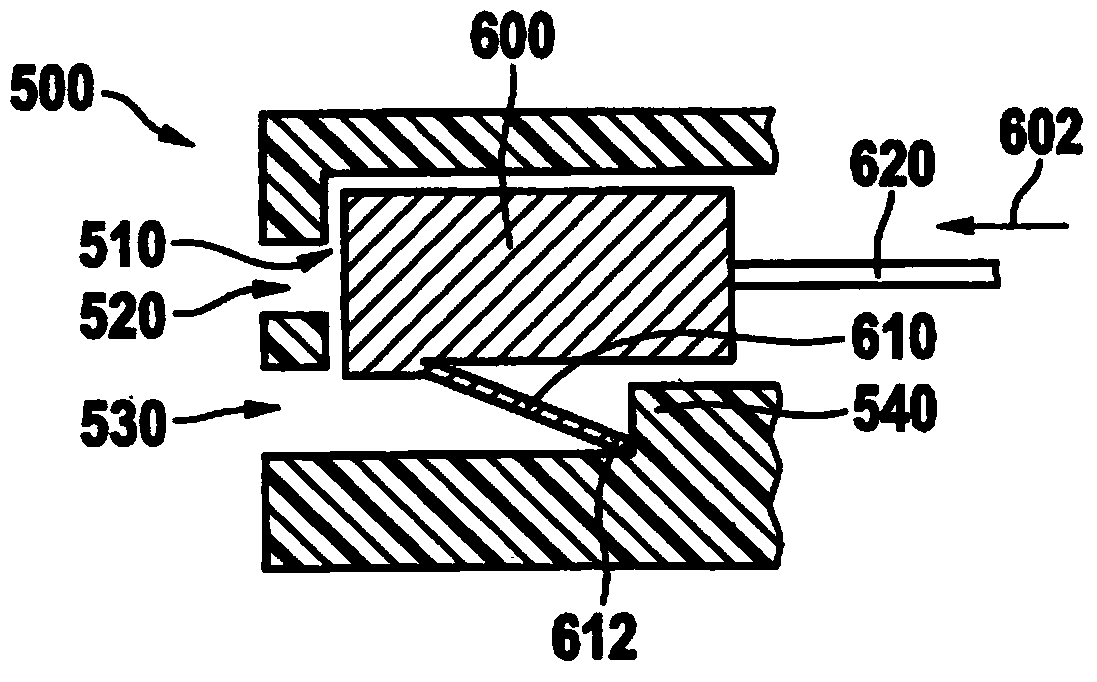

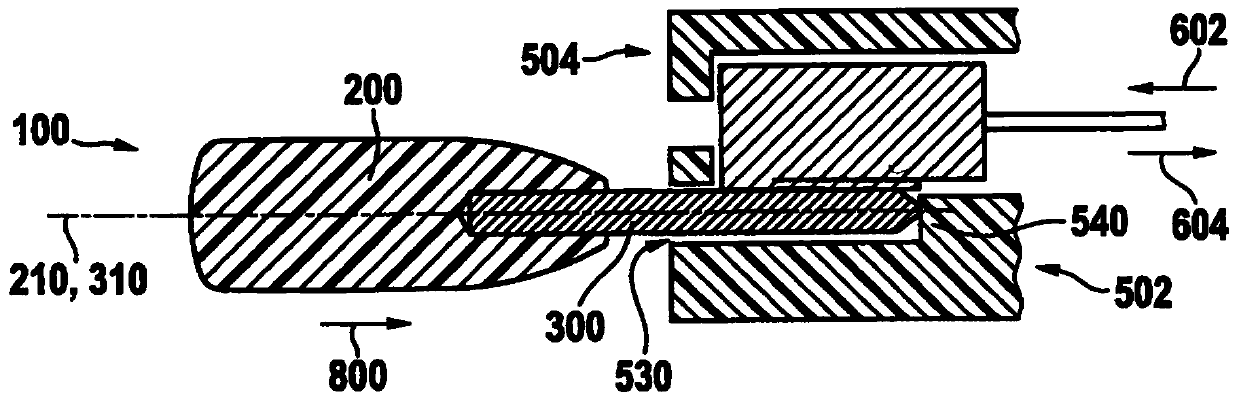

[0039] exist Figures 1a to 1d A contact chamber 510 of a plug connector 500 according to the prior art is shown in FIG. The contact chamber 510 has a plug contact opening 512 on the plug contact side 502 , through which the electrical plug contact 600 can be inserted into the contact chamber 510 in the plug contact insertion direction 602 . Furthermore, the plug connector 500 has a removal side 504 facing away from the plug contact side 502 . At least one contact opening 520 is provided in the removal side 504 , through which the plug-in contact 600 can be mechanically and electrically contacted with an electrical contact (not shown). The electrical plug contact 600 inserted into the contact chamber 510 has an electrical connection line 620 fastened thereto.

[0040] as in Figure 1b As shown in , the electrical plug contact 600 is locked or latc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com