High-power-factor low-ripple single-stage correcting circuit

A high power factor, correction circuit technology, applied in the direction of output power conversion devices, high-efficiency power electronic conversion, electrical components, etc., can solve the problems of large number of components used, high output ripple current, complex circuit structure, etc., to achieve The effect of reducing the number of uses, reducing the output ripple current, and simplifying the circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

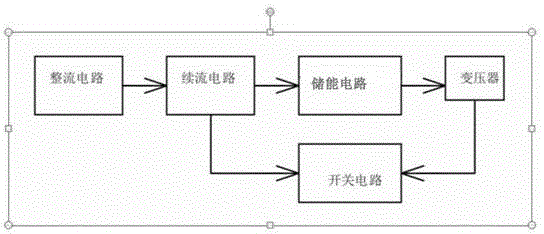

[0022] Such as figure 1 As shown, a single-stage correction circuit with high power factor and low ripple of the present invention includes a rectifier circuit, a freewheeling circuit, an energy storage circuit, a switch circuit and a transformer, and a freewheeling circuit is connected between the rectifier circuit and the energy storage circuit, The freewheeling circuit and the transformer share a switching circuit, and the energy storage circuit adopts a series charging and parallel discharging structure.

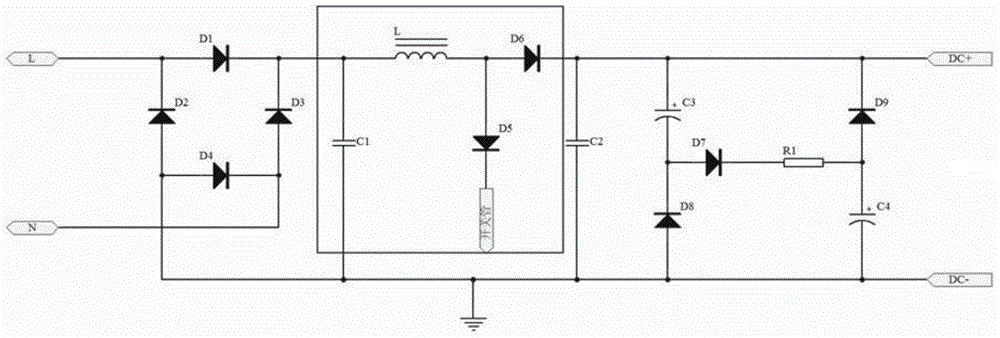

[0023] Such as figure 2 As shown, the rectifier circuit is formed by connecting diodes D1, D2, D3 and D4. The freewheeling circuit includes an energy storage inductor L, a diode D5, a diode D6 and a capacitor C1. The energy storage circuit is composed of capacitors C3, C4, diodes D7, D8, D9 and resistor R1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com