Single-stage step-up inverter

A booster and inverter technology, applied in the field of single-stage booster inverters, can solve the problems of high cost and poor output effect, and achieve high power factor, reduced circuit cost, and good output effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

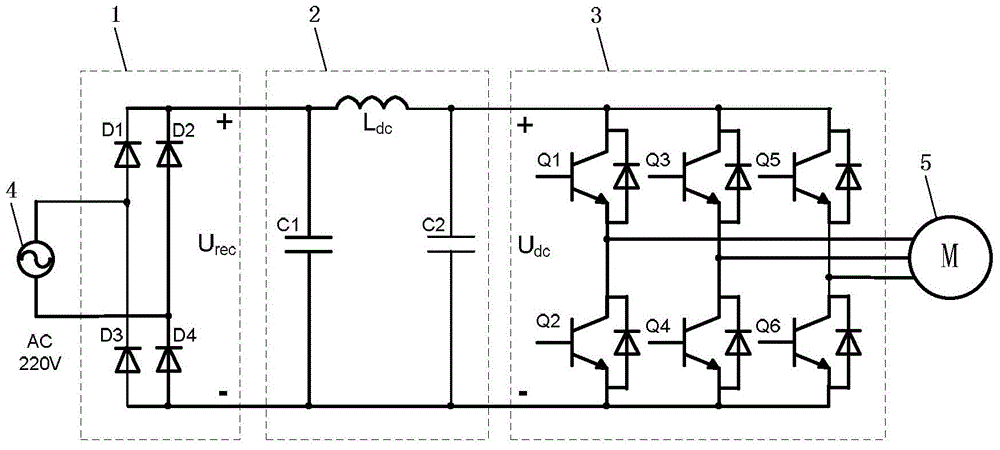

[0020] image 3 It is a circuit diagram of a single-stage boost inverter according to an embodiment of the present invention. Such as image 3 As shown, the circuit includes: input rectification circuit 1, π-type circuit 2 and inverter circuit 3; input rectification circuit 1 is connected to external AC power 4, π-type circuit 2 is connected to input rectification circuit 1 and inverter circuit 3, and inverter circuit 3 is connected to an external load 5; wherein,

[0021] The π-type circuit 2 includes: a first capacitor C1, a second capacitor C2 and an inductor L dc ; The first capacitor C1 is connected in parallel with the second capacitor C2, and the inductance L dc Connected to the parallel circuit of the first capacitor C1 and the second capacitor C2;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com