Electrolytic-free capacitor power converter and control method for permanent magnet synchronous motor drive system

A permanent magnet synchronous motor and power converter technology, applied in motor control, motor generator control, AC motor control and other directions, can solve the problems of DC bus voltage fluctuation, poor static and dynamic performance of the motor, and achieve high input power factor, The effect of high power factor and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

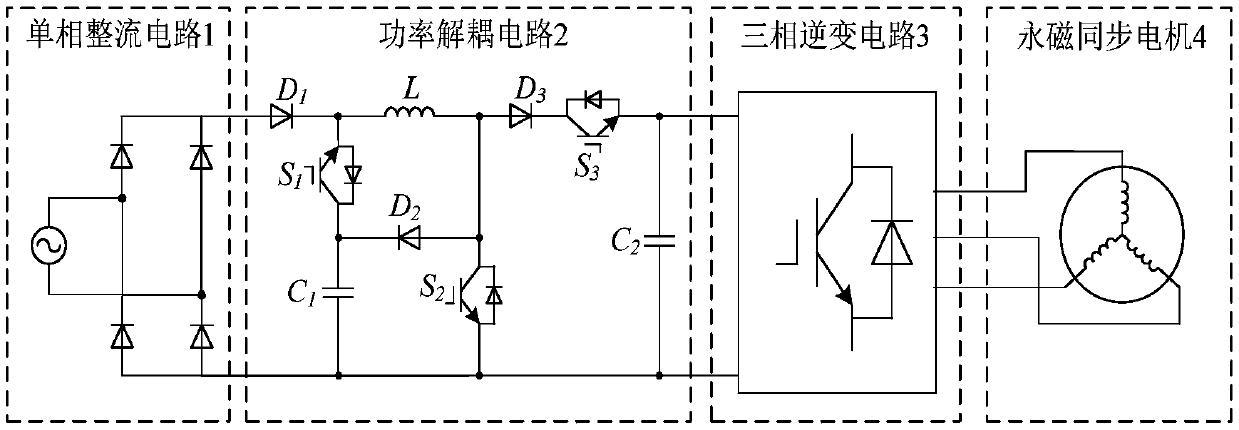

[0027] Such as figure 1 As shown, the non-electrolytic capacitor power converter for the permanent magnet synchronous motor drive system proposed by the present invention is composed of a single-phase rectifier circuit 1, a power decoupling circuit 2 and a three-phase inverter circuit 3 connected in series in sequence. The input end of the single-phase rectification circuit 1 is connected to the grid, the positive pole of the output end of the single-phase rectification circuit 1 is connected to the positive pole of the power decoupling circuit 2, the negative pole of the output end of the single-phase rectification circuit 1 is connected to the negative pole of the power decoupling circuit 2 and the three-phase The negative poles of the inverter circuit 3 are connected. The positive pole of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com