Automatic control method for burst luminous power

A technology of transmitting power and power, which is applied in electromagnetic wave transmission systems, electrical components, transmission systems, etc., and can solve the problems of inability to measure short data packets and ultra-short data packets, and short light-emitting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

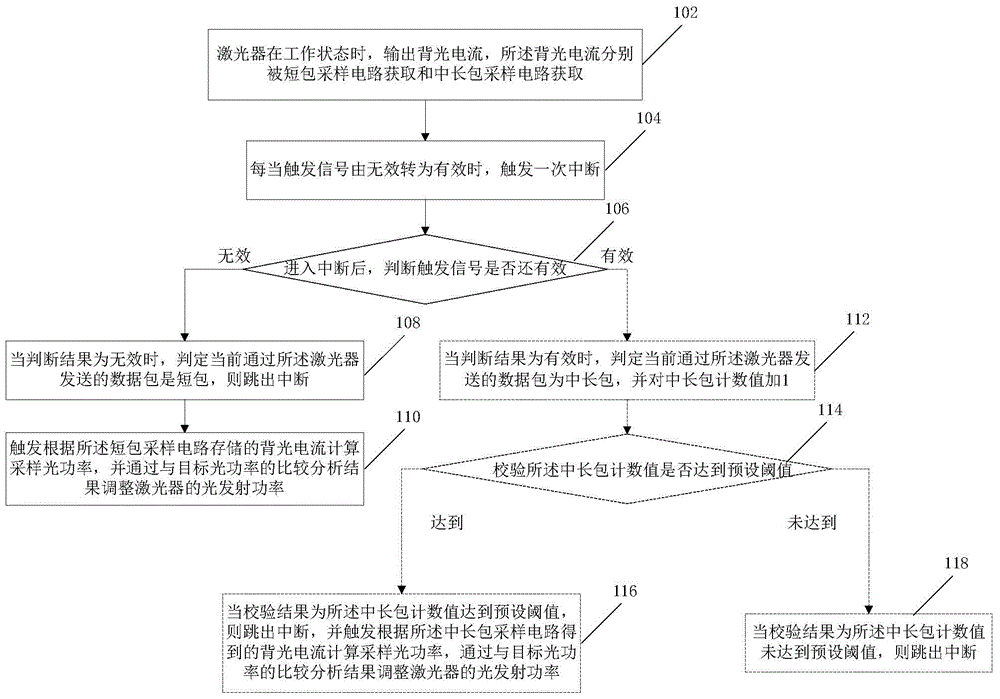

[0022] Such as figure 1 Shown is a flow chart of a method for automatic control of burst optical power provided by the present invention, the laser works within the validity period of the trigger signal, and the method includes the following steps:

[0023] In step 102, when the laser is in the working state, the backlight current is output, and the backlight current is obtained by the short packet sampling circuit and the medium and long packet sampling circuit respectively, wherein the short packet sampling circuit can sample and hold the backlight current at the current moment .

[0024] Wherein, the short-packet sampling circuit and the medium-long-packet sampling circuit may be circuits composed of independent electrical devices, or may be implemented based on internal circuits in an integrated chip (for example: MAX3643 or MCU), which are not specifically limited here.

[0025] In a specific implementation manner, the simplest implementation manner of the medium and lon...

Embodiment 2

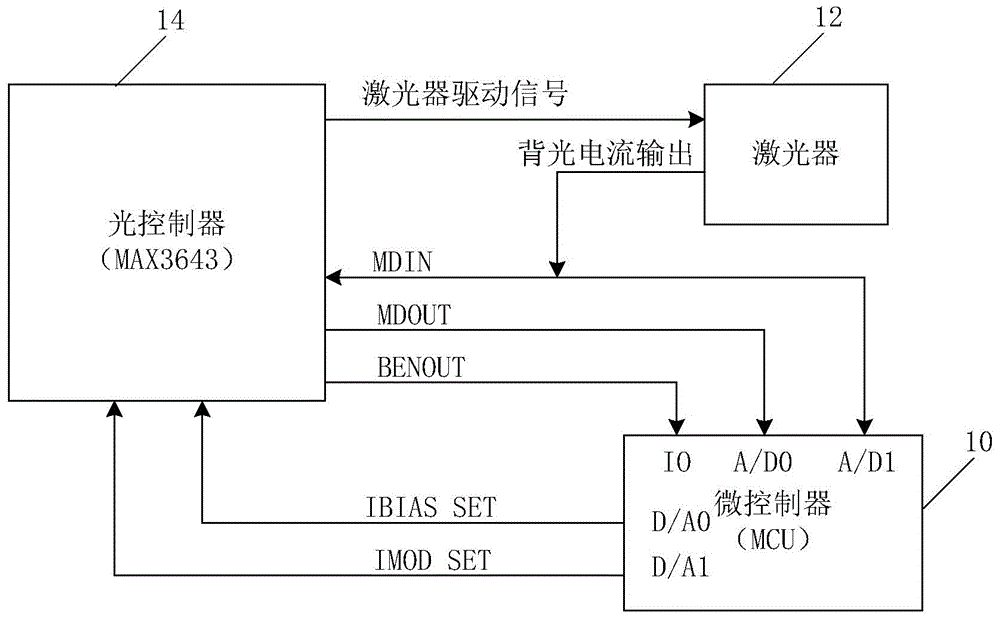

[0053] Such as figure 2 Shown is a schematic structural diagram of a system for automatic control of burst optical power provided by an embodiment of the present invention. figure 2 It can be seen that a system for automatic control of burst optical power provided by the present invention includes an optical driver 14, a microcontroller 10 and a laser 12, the optical driver 14 is used to control the operation of the laser 12, and the microcontroller 10 is used for calculating And adjust the optical power controlled by the laser driver 14, the optical driver 14 generates a trigger signal to control the work of the laser 12, and the system specifically includes in realizing the method of the present invention:

[0054] The laser 12 works within the valid period of the trigger signal, and outputs a backlight current; the backlight current is input to the short packet sampling circuit of the optical driver 14 for storage, and is used to calculate the sampling optical power of th...

Embodiment 3

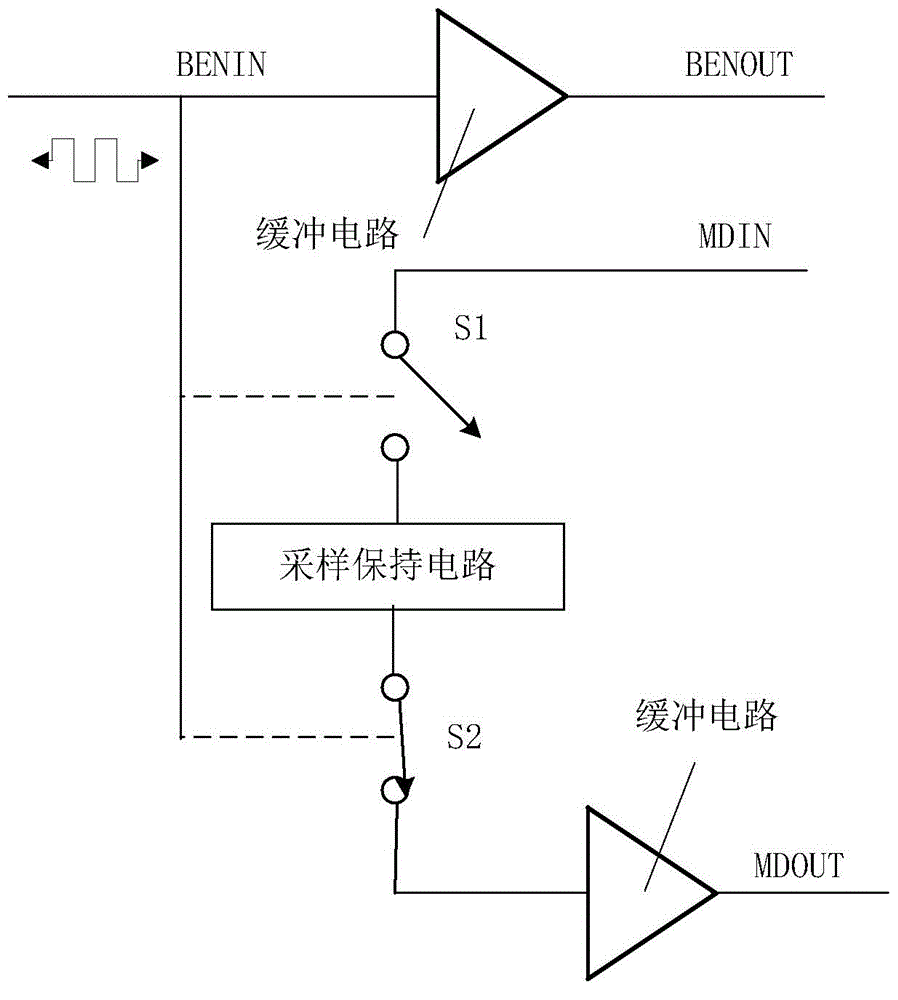

[0071] Such as figure 2 As shown, this embodiment provides a schematic structural diagram of a system for automatic control of burst optical power, as shown in figure 2 As shown, this embodiment will combine figure 2 The relevant pins of the specific optical driver 14 (MAX3643) and the corresponding pins of the microcontroller 10 (MCU) are used to illustrate this specific implementation. Compared with Embodiment 2, the corresponding system module functions of this embodiment are as follows:

[0072] The laser 12 works within the valid period of the trigger signal, which is specifically a high-frequency BURST-ENABLEIN (abbreviated as: BUSIN), and is carried in the laser driving signal sent by the optical driver 14 to the laser 12 .

[0073] When the laser 12 is working, it outputs backlight current. The optical power of the backlight is proportional to the optical power of the light emitted from the front of the laser, therefore, the optical power of the light emitted by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com