Sealing device

A technology for sealing devices and sealing components, which is applied to the sealing of engines, engine components, mechanical equipment, etc., and can solve problems such as reduced sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

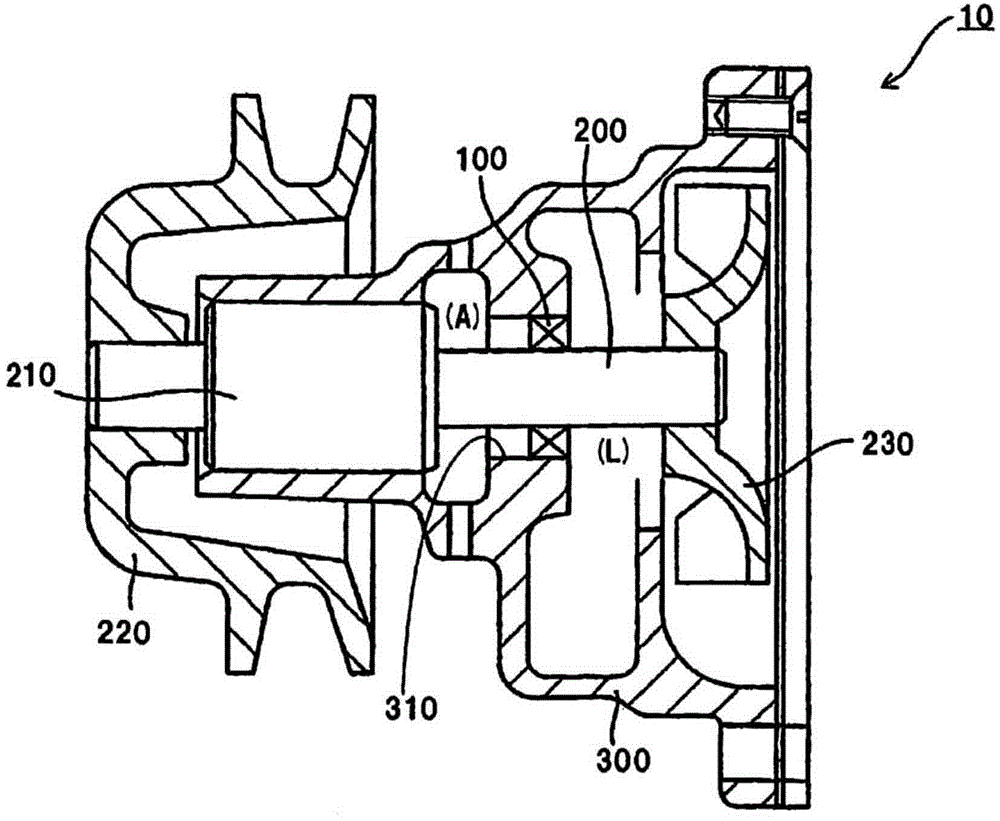

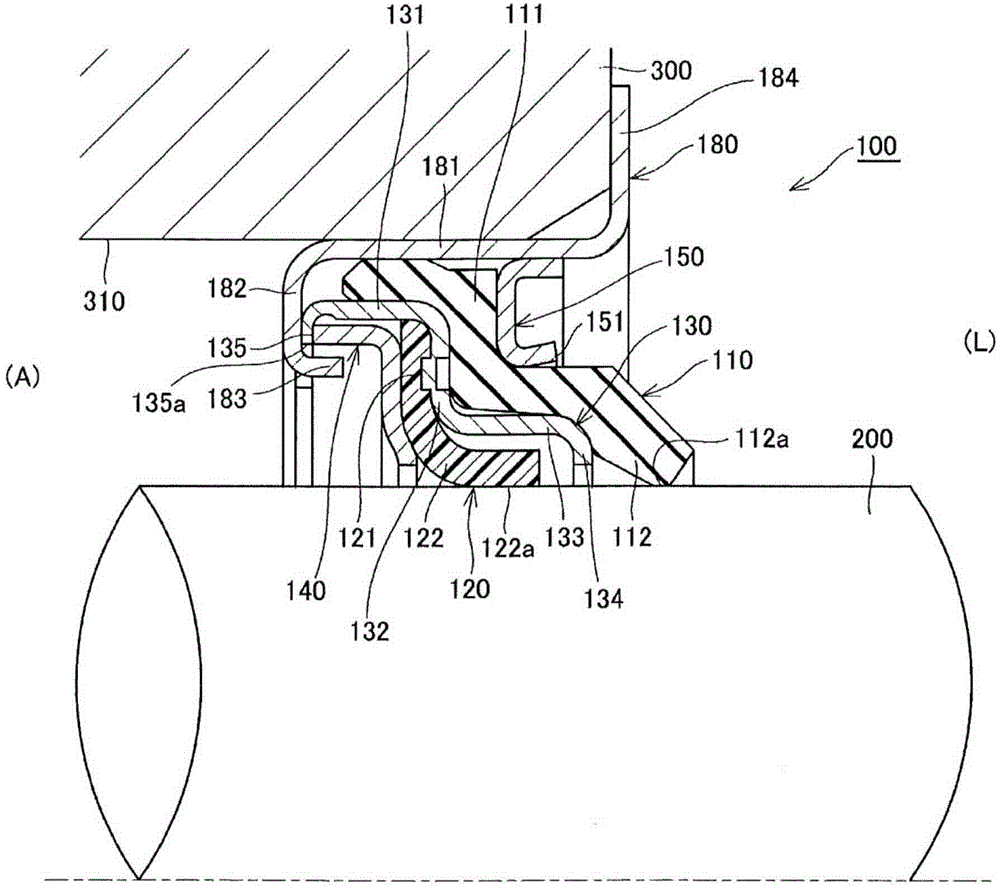

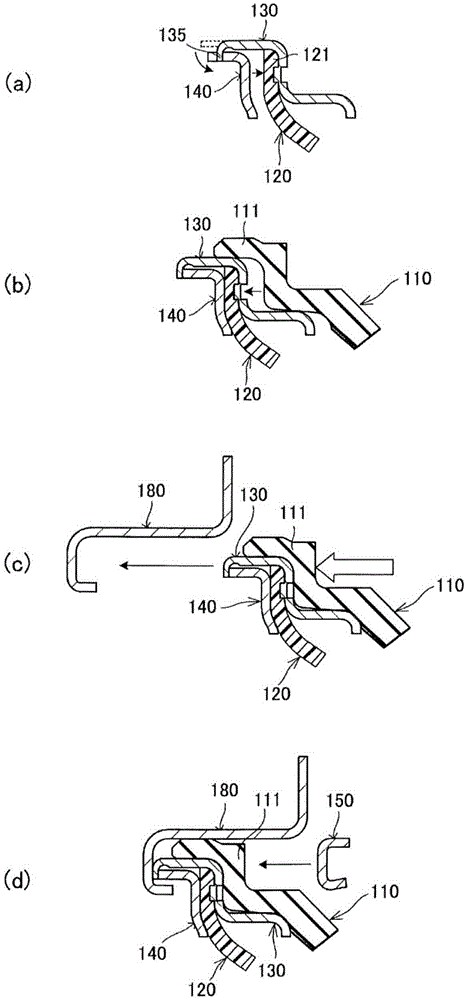

[0069] refer to Figure 1~3 The sealing device according to Embodiment 1 of the present invention will be described.

[0070] refer to figure 1 An example of a sealing device according to an embodiment of the present invention will be described. figure 1It is a cross-sectional view showing an example of a sealing device according to an embodiment of the present invention, and is a schematic cross-sectional view of an automotive water pump 10 . The water pump 10 has a rotating shaft 200 and a shaft housing 300 having a shaft hole 310 passing through the rotating shaft 200 . A bearing 210 for smoothly rotating the rotating shaft 200 is installed on the rotating shaft 200 . A pulley 220 is attached to one end of the rotating shaft 200, and the pulley 220 is given rotational driving force by a belt not shown, and an impeller 230 for pressure-feeding cooling water is attached to the other end of the rotating shaft 200. In order to prevent the cooling water from leaking to the o...

Embodiment 2

[0098] refer to Figure 4 , Figure 5 , Embodiment 2 of the present invention will be described. Figure 4 It is a cross-sectional view of the use state of the sealing device 100 according to the second embodiment of the present invention. Figure 5 (a) is a perspective view of the sealing device 100 of Embodiment 2 of the present invention, Figure 5 (b) is a side view seen from the atmosphere side (A side).

[0099] In this embodiment, a modified example of the casing in the above-mentioned first embodiment will be described. Since the other configurations and functions are the same as in the first embodiment, the same components are given the same reference numerals and their descriptions are omitted.

[0100]Depending on the relationship between the rotating shaft 200 and the inner diameter of the shaft hole 310 of the shaft housing 300 , there are cases where the annular gap to be sealed by the sealing device 100 becomes large. Therefore, in the sealing device 100 of...

Embodiment 3

[0102] Image 6 Embodiment 3 of the present invention is shown. In this embodiment, a metal sleeve 250 fitted on the outer peripheral surface of the rotating shaft 200 is used. Since the other structures and functions are the same as those in Embodiments 1 and 2, the same components are given the same reference numerals and their descriptions are omitted.

[0103] A sleeve 250 is provided to facilitate the installation of the rotating shaft 200 in the shaft hole 310 of the shaft housing 300 and to protect the outer peripheral surface of the rotating shaft 200 . As the rotating shaft 200 rotates, the sleeve 250 slides on the sliding portion 112 a of the rubber lip 112 and the sliding portion 122 a of the resin lip 122 and rotates. That is, in the present invention, the sliding portion 112a of the rubber lip 112 and the sliding portion 122a of the resin lip 122 are not limited to directly sliding on the outer peripheral surface of the rotating shaft 200, but may also slide on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com