A kind of β-tcp/pgs composite scaffold and its preparation method and application

A composite scaffold and porous scaffold technology, applied in medical science, prosthesis, etc., can solve the problems of poor toughness, β-TCP biological activity, limited improvement of β-TCP toughness and strength, etc., to achieve rapid repair and promote bone repair. , the effect of promoting vascularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] Synthesis and Purification of PGS Prepolymer

[0105] PGS prepolymers are synthesized by a two-step process.

[0106] Step 1: Under an argon atmosphere, react sebacic acid and glycerin at a molar ratio of 1:1 at 130°C for 24 hours;

[0107]The second step: the product of the first step was continued to react for 24 hours at 130° C. under vacuum conditions to obtain a PGS prepolymer.

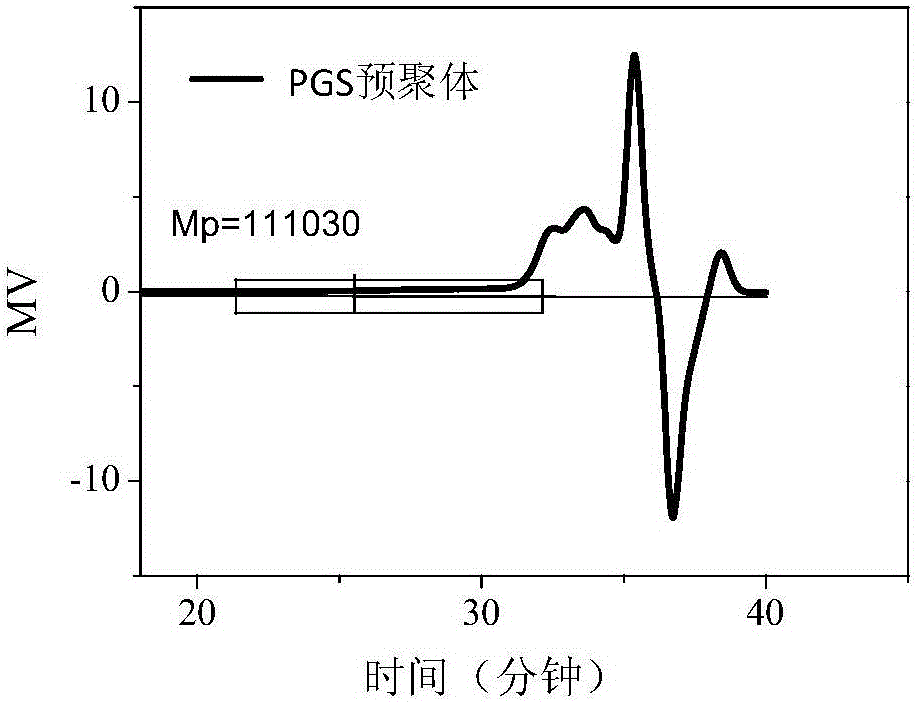

[0108] Purification is then carried out. Firstly, the PGS prepolymer is dissolved in ethanol, the obtained emulsion is allowed to stand for a period of time, and the supernatant liquid is poured off. The obtained PGS prepolymer was placed in a dialysis bag and dialyzed to obtain a purified PGS prepolymer with a molecular weight of 12000 Da and a dispersion coefficient of 1.19.

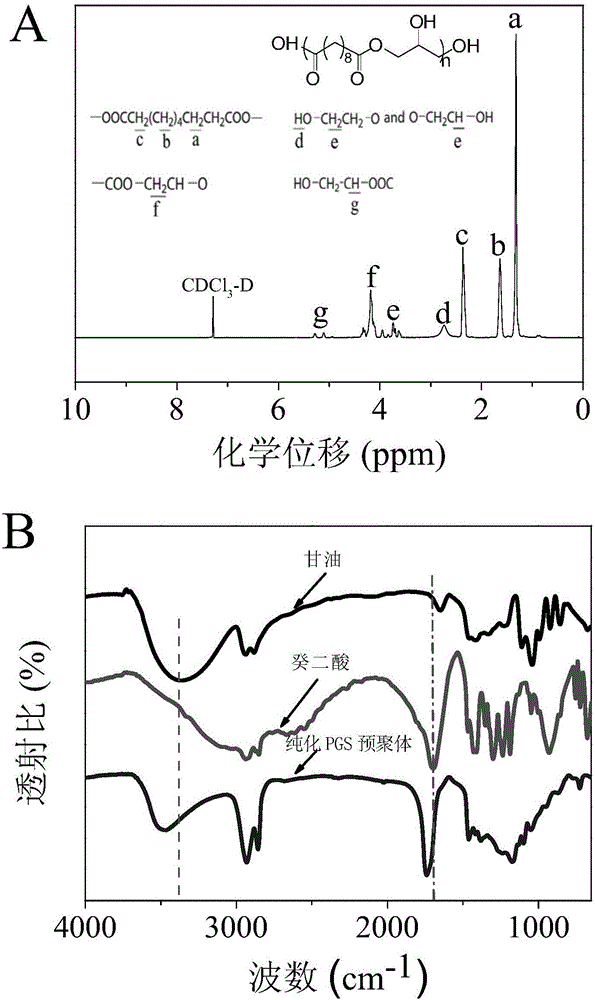

[0109] Purification of PGS prepolymer 1 H-NMR such as figure 1 Shown in A. The proton peaks at 1.31, 1.62 and 2.35ppm mainly indicate the presence of sebacic acid units in the synthesized polymer chains, and t...

Embodiment 2

[0113] Synthesis of β-TCP Nanoparticles and Preparation of β-TCP Porous Scaffold

[0114] 0.4mol Ca(NO 3 ) 2 4H 2 O and 0.4mol(NH 4 ) 2 HPO 3 Dissolve in 200ml ultrapure water respectively, and stir rapidly for 30min to obtain Ca salt and P salt solutions. Add the Ca solution to the P solution drop by drop (1-2 drops / second), while maintaining constant stirring and adding the prepared ammonia water (2M) to adjust the pH value of the mixed solution to be stable at 7.0-7.5. After the dropwise addition was completed, the stirring was stopped, and the solution was allowed to stand for 2 hours to allow the solution to precipitate naturally, and the supernatant liquid was poured off. Then put the obtained precipitate into a centrifuge bottle, carry out centrifugation (6000r / min, 10min), wash with ultrapure water in the next step, ultrasonic (10min), continue to centrifuge, then repeat the water wash 2 times, and then wash it again with absolute ethanol After centrifugation, t...

Embodiment 3

[0121] Preparation of β-TCP / 10P-Unc Porous Scaffold

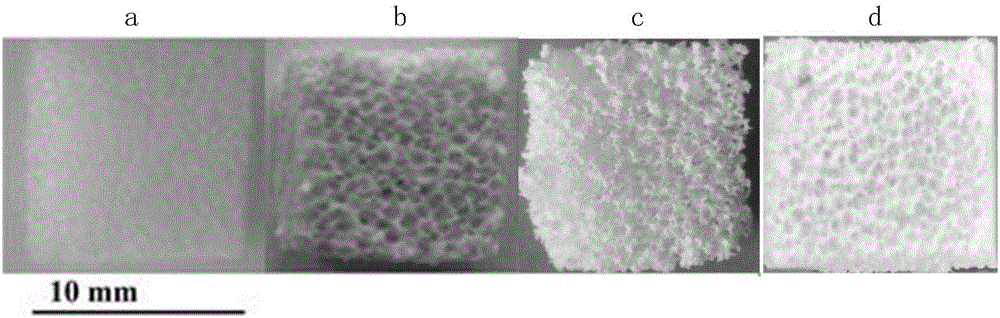

[0122] The prepared PGS prepolymer (PGS-1:1, prepared in Example 1) was formulated into a solution with a concentration of 10 mg / ml using absolute ethanol as a solvent. Place the β-TCP porous scaffold (0.2 g in weight) in a 24-well plate, add 2 ml of PGS solution to completely submerge the scaffold, and then place the porous plate in a fume hood for 3 to 5 hours to remove ethanol. Then the scaffold was freeze-dried at -50° C. under vacuum conditions for 24 hours to obtain the product β-TCP / 10P-Unc porous scaffold. The size of the pores is between 300-500 microns. The porosity is 90±2%. The maximum compressive strength is 0.02±0.01MPa, and the fracture deformation is 120±32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap