Exhaust block and exhaust structure for deep-cavity part of core-making mold of hot-core box

A technology of exhaust block and hot core box, which is applied in the direction of casting and molding equipment, can solve the problems of difficult cleaning methods and easily damaged molds, and achieve the effects of simple structure, convenient production and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

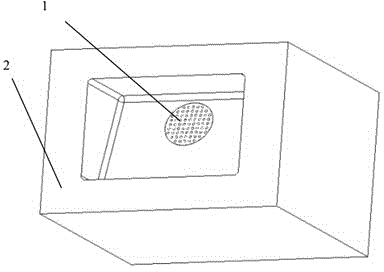

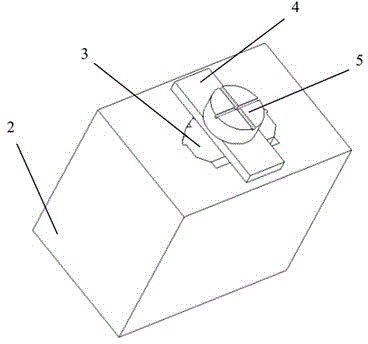

[0020] The present invention will be further described below in conjunction with accompanying drawing:

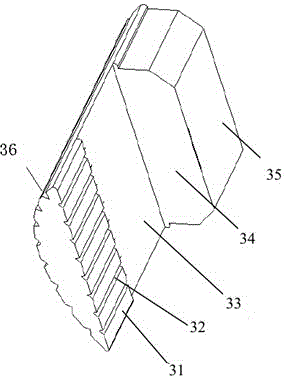

[0021] like figure 2 As shown in the exhaust block for the deep cavity of the hot core box core making mold, the exhaust block 3 is in an inverted L shape, and its side wall surface is an arc surface 36, and upper and lower bars are separated on the arc surface 36. Through the exhaust groove 32, the other side wall surface of the exhaust block 3 opposite to the arc surface 36 is divided into a vertical exhaust surface 35, a horizontal buffer surface 34, a vertical dredging surface 33 and a vertical exhaust surface from top to bottom. The air distribution surface 31 is straight, and the vertical unblocking surface 33 is slightly lower than the vertical air distribution surface 31, and the vertical air distribution surface 31 is provided with an exhaust groove 32 that runs through the entire vertical air distribution surface 31 up and down.

[0022] The cross-section of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com