Bolt machining clamp for lathe

A bolt and collet technology, which is applied in the field of bolt processing collets for lathes, can solve the problems of reduced productivity, damage to the outer diameter of the bolt, and troublesome clamping, so as to improve production efficiency, save time and effort in clamping, and facilitate clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

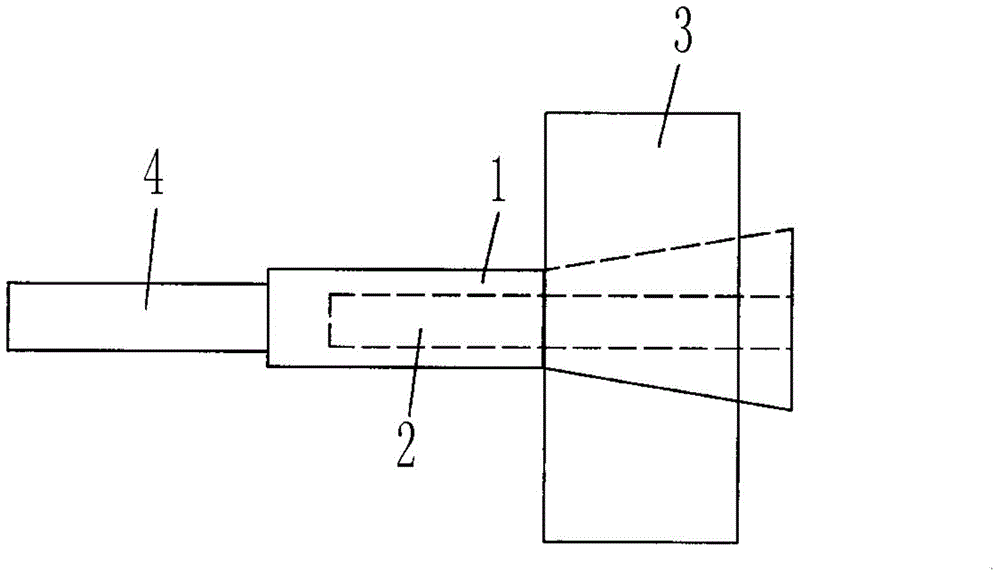

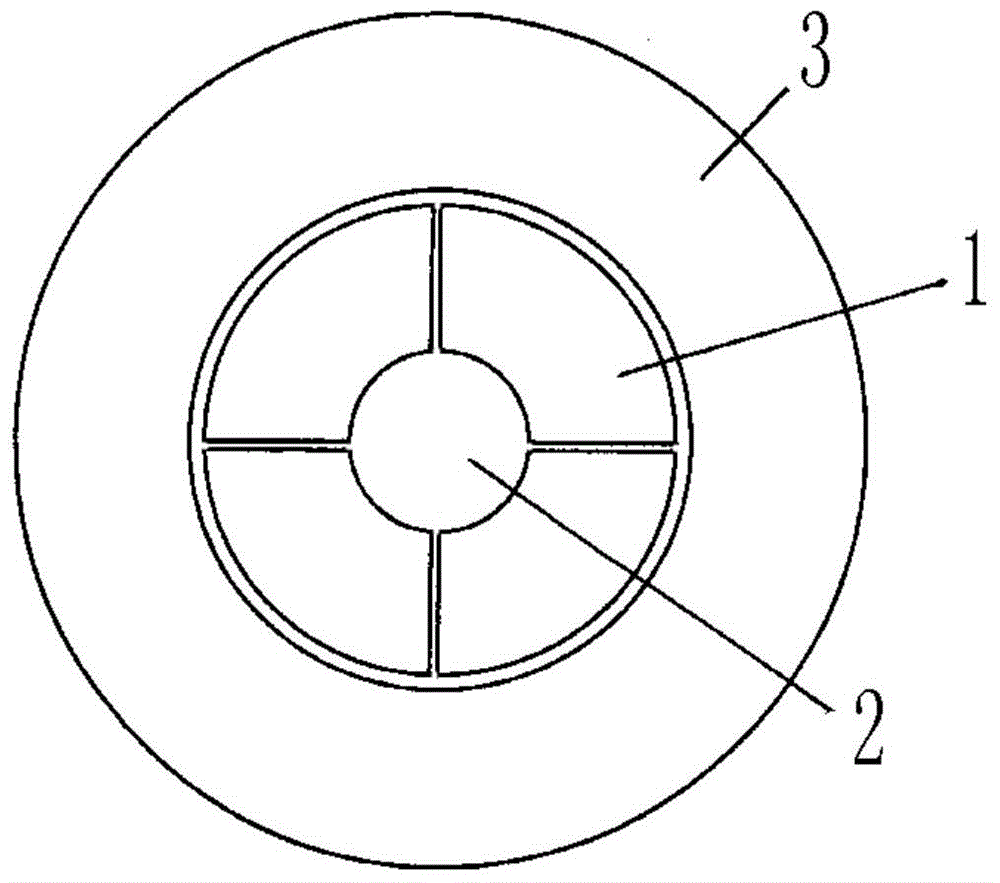

[0010] As shown in Figures 1 and 2, the present invention drills a clamping hole 2 at the inner center of the jacket 1, and the jacket 1 with a tapered structure at one end is equally divided into four equal parts, and the outside of the jacket 1 with a tapered structure There is a jacket 3 matched with it, and the pull rod 4 is connected to the other end of the jacket. Through the above settings, the present invention is used for lathe bolt processing. The round bolt to be processed is inserted into the clamping hole 2, and the pull rod 4 is pulled to make the jacket 1 move backward in the jacket. The tapered jacket 1 clamps the bolt. Once it is fixed, it can be processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com