A tapping jig

A wire clamp and screw technology, which is applied in the field of machining, can solve the problems that the force of the workpiece cannot be effectively dispersed, it is difficult to control the tightening force, and the tapping direction is inclined. The effect of dispersing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

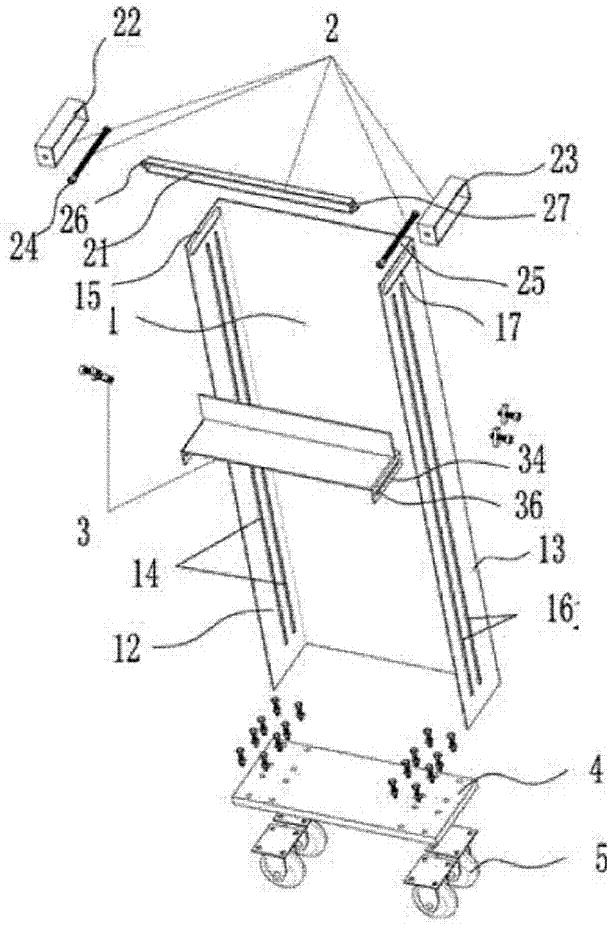

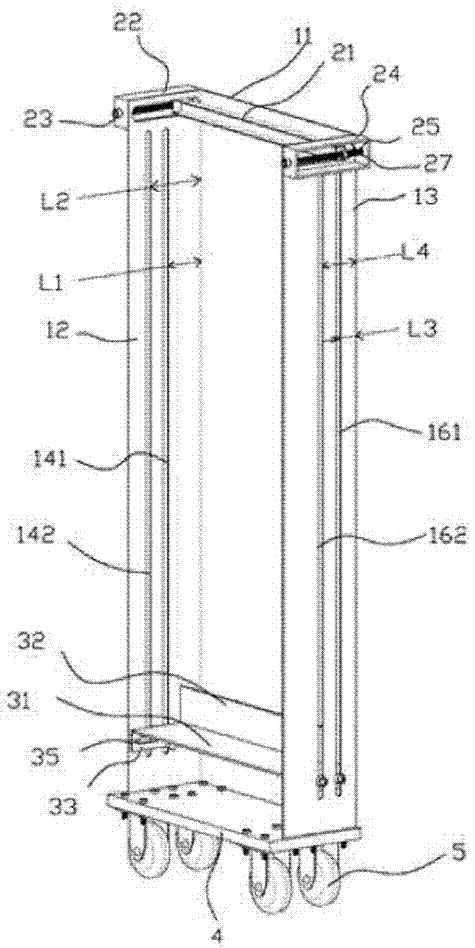

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

[0036] as attached figure 1 with 2As shown, a tapping fixture includes a U-shaped plate body 1, a compression set 2 for pressing a workpiece, and a support set 3 for supporting the workpiece. The U-shaped plate body 1 is folded from a plate It is formed by bending, including a main board 11, a first side board 12 and a second side board 13. The first side plate 12 is respectively provided with a first fixing part 14 for fixing the supporting set and a first mounting part 15 for installing the pressing set, and the second side plate 13 is respectively provided with a The second fixing part 16 of the supporting sleeve and the second mounting part 17 for installing the pressing sleeve, the first fixing part 14 is two vertical fixing slots respectively the first front slot 141 and the first front slot 141. The first middle groove 142, the second fixing member 15 is two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com