Thread adjusting clamp and screw installation method

A thread adjustment and fixture technology, which is applied to workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of high labor intensity, high failure rate, and high cost, and achieve reduced labor intensity, high pass rate, and consumption. short-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

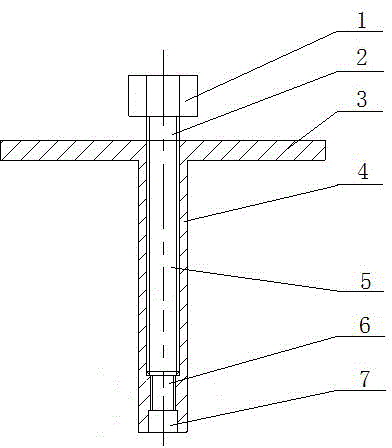

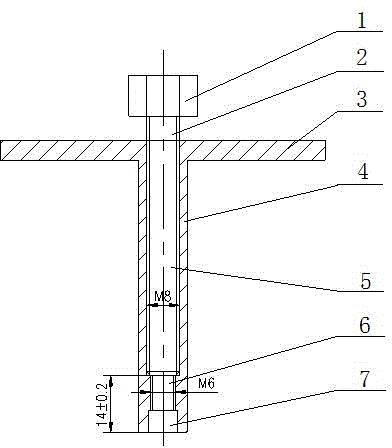

[0019] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the threaded adjustment fixture and screw installation method proposed according to the present invention will be described in detail as follows

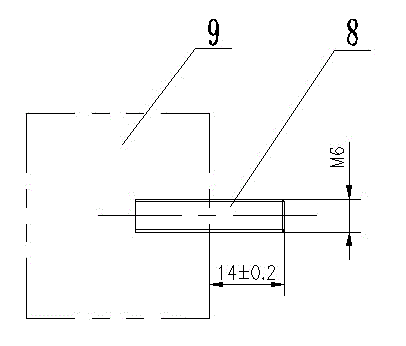

[0020] see figure 1 , a threaded adjustment fixture of the present invention, comprising a screw rod 2 and a stop rod 4, wherein: the stop rod 4 is provided with an internal thread segment A5, an internal thread segment B6 and a through hole 7 in sequence, and the internal thread segment A5 and The external thread of the screw rod 2 matches, and the diameter of the internal thread section B6 matches the screw to be installed; the length of the internal thread section B6 and the through hole 7 is equal to the length of the exposed part of the required installation screw; the internal thread section A5 and The diameters of the through holes 7 are larger than the diameter of the internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com