A double-sided gravure wax printing machine for real wax anti-dyeing printing production

A wax printing machine and wax proofing technology, applied in gravure rotary printing machine, printing machine, rotary printing machine and other directions, can solve the problems of unclear printing pattern, poor printing precision, long distance between flowers, etc., to achieve fine printing effect, The effect of high precision and short distance to flower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with preferred embodiments.

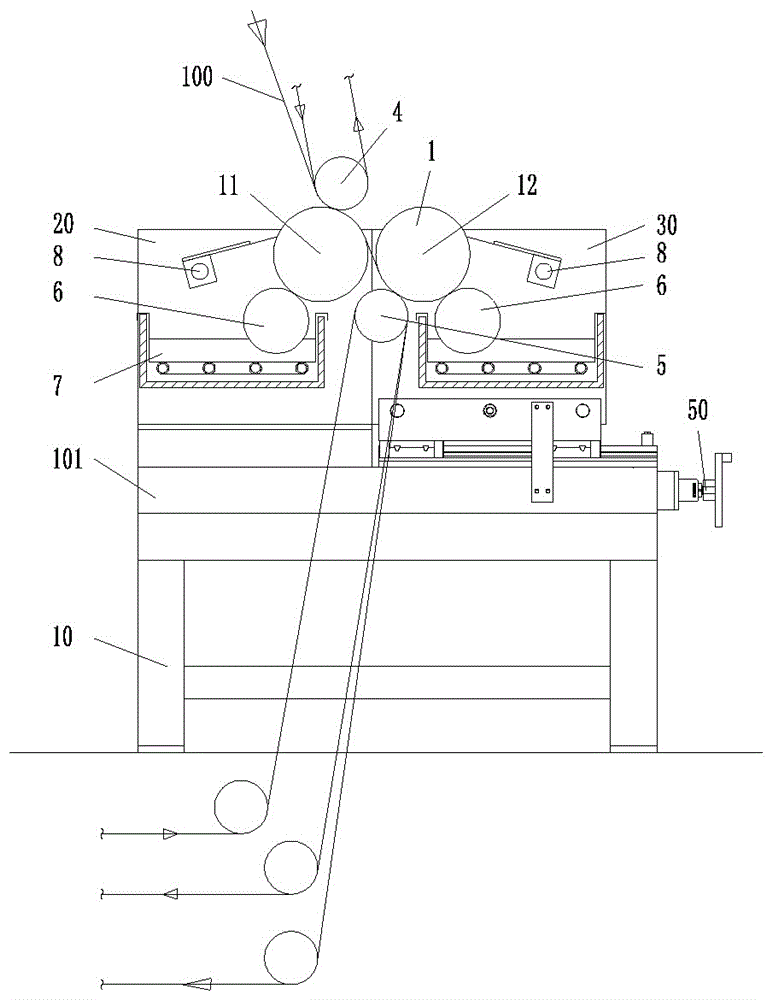

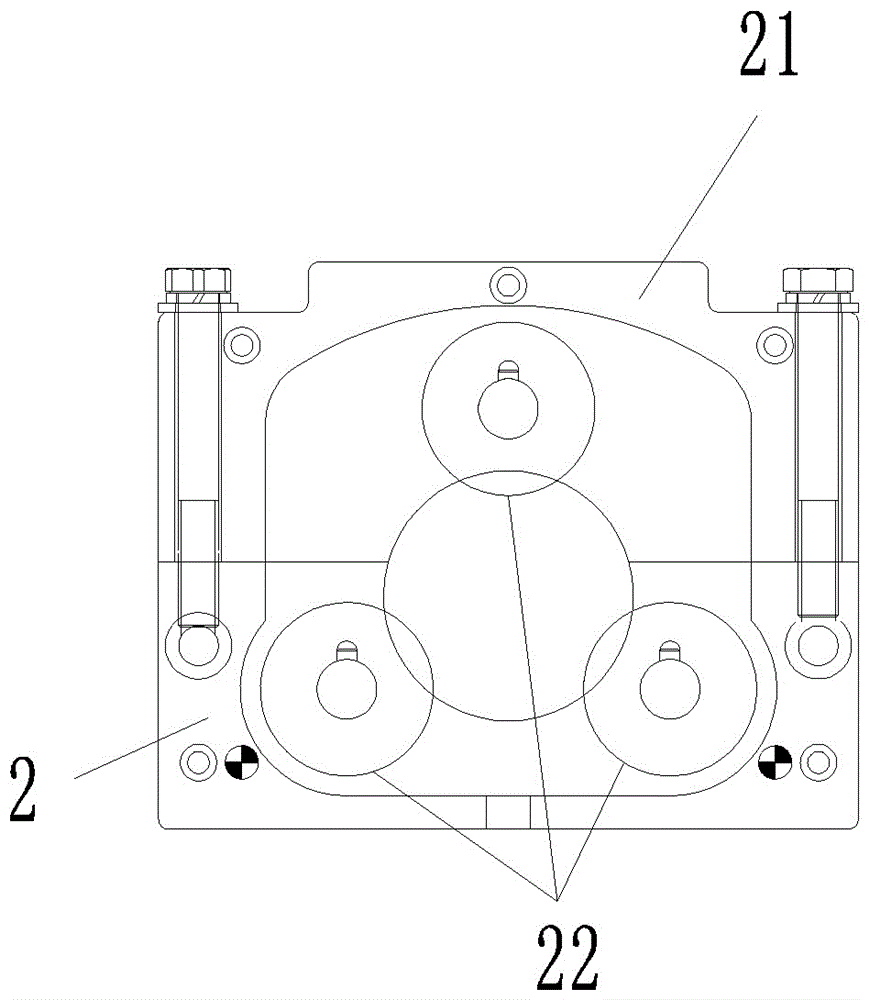

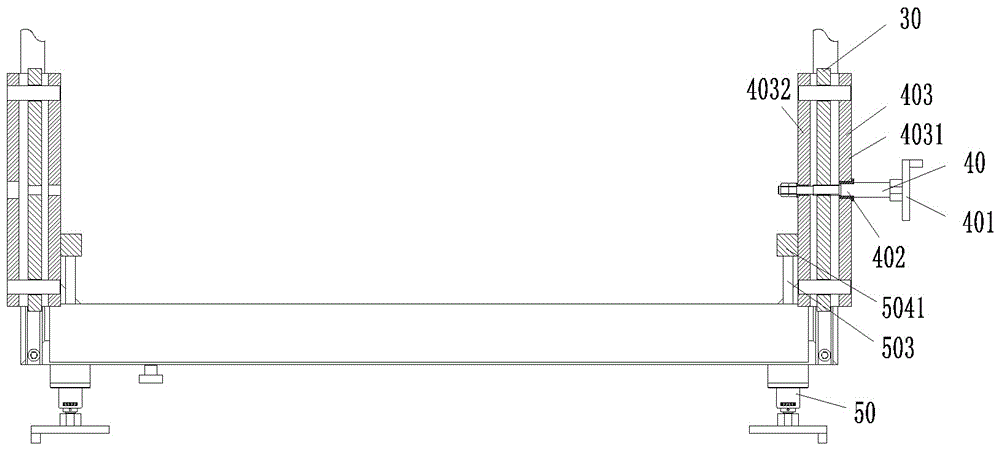

[0020] Such as figure 1 and figure 2 As shown, a double-sided gravure wax printing machine for real wax anti-dyeing printing production includes a frame 10 and a printing roller group 1; the frame 10 is provided with a first The box body 20 and the second box body 30 that are movably installed on the frame base 101, the two ends of the first box body 20 and the second box body 30 are respectively equipped with a bearing seat assembly 2, and the two ends of the printing roller shaft 13 pass through The passing bearing seat assembly 2 is erected on the first box body 20 and the second box body 30 respectively; the embossing roller set 1 includes front embossing rollers 11 and back embossing rollers 12 installed sequentially along the cloth feeding direction. The top of the roller 11 is provided with an upper pressing roller 4 tangential to it, and the lower side of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com