Container and its locking mechanism

A locking mechanism and container technology, applied in the field of containers, can solve the problems of reduced locking reliability, heavy operator workload, increased storage costs, etc., to achieve enhanced locking reliability, reduced transportation and storage costs, and a small and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

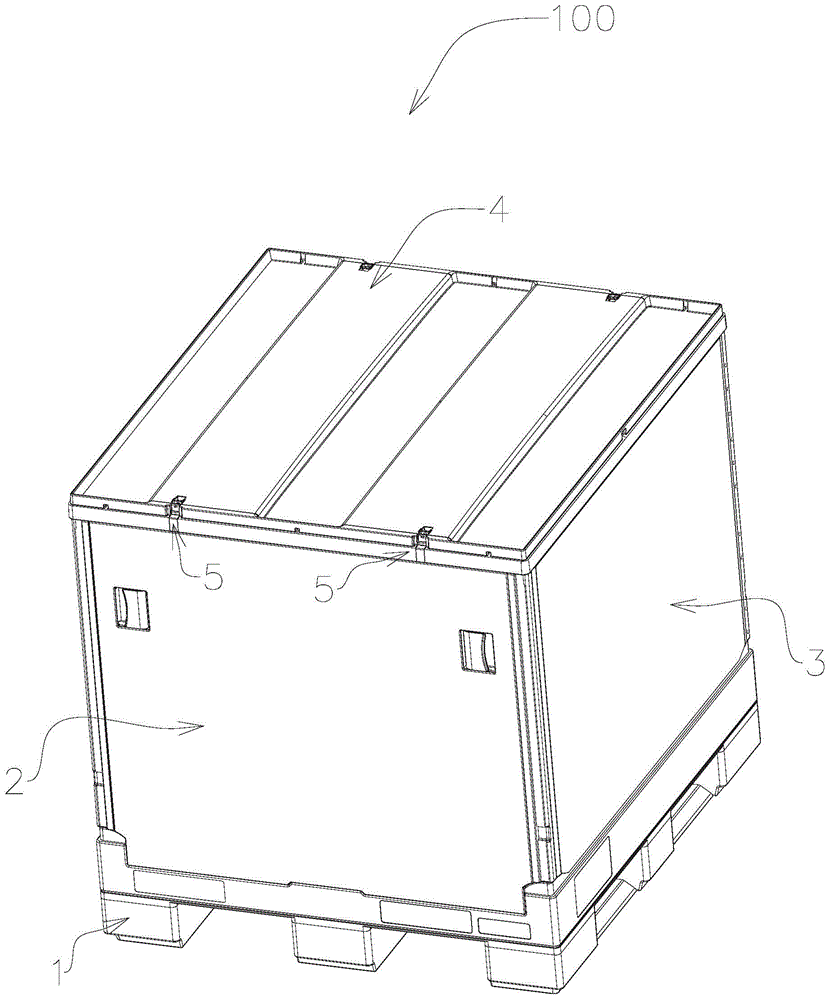

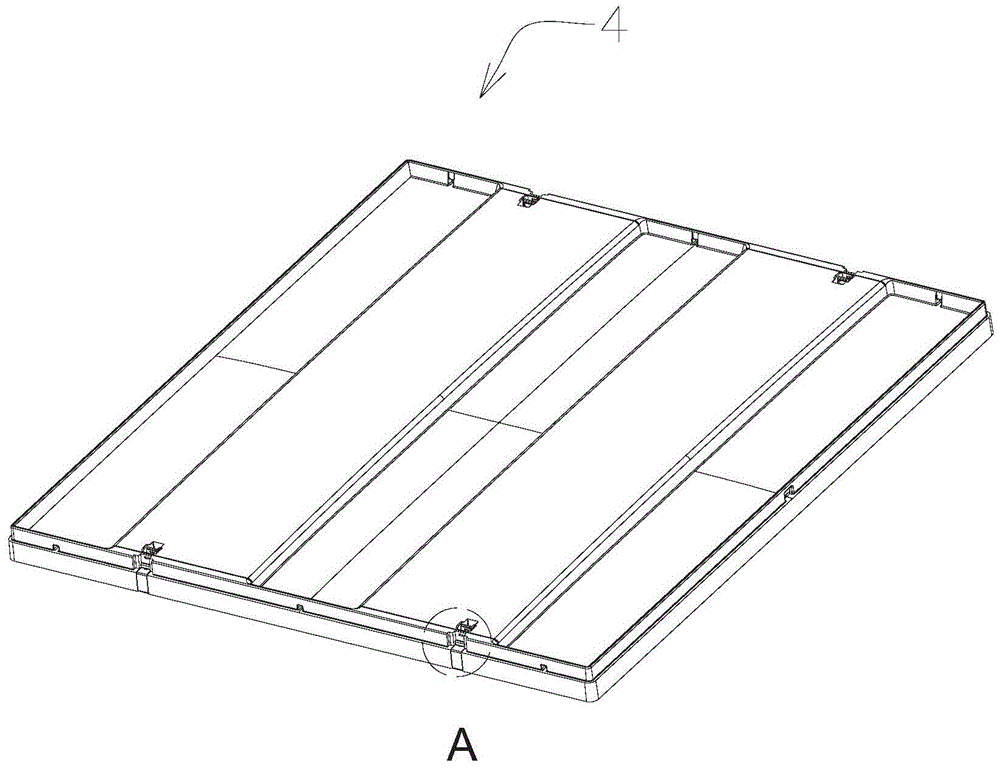

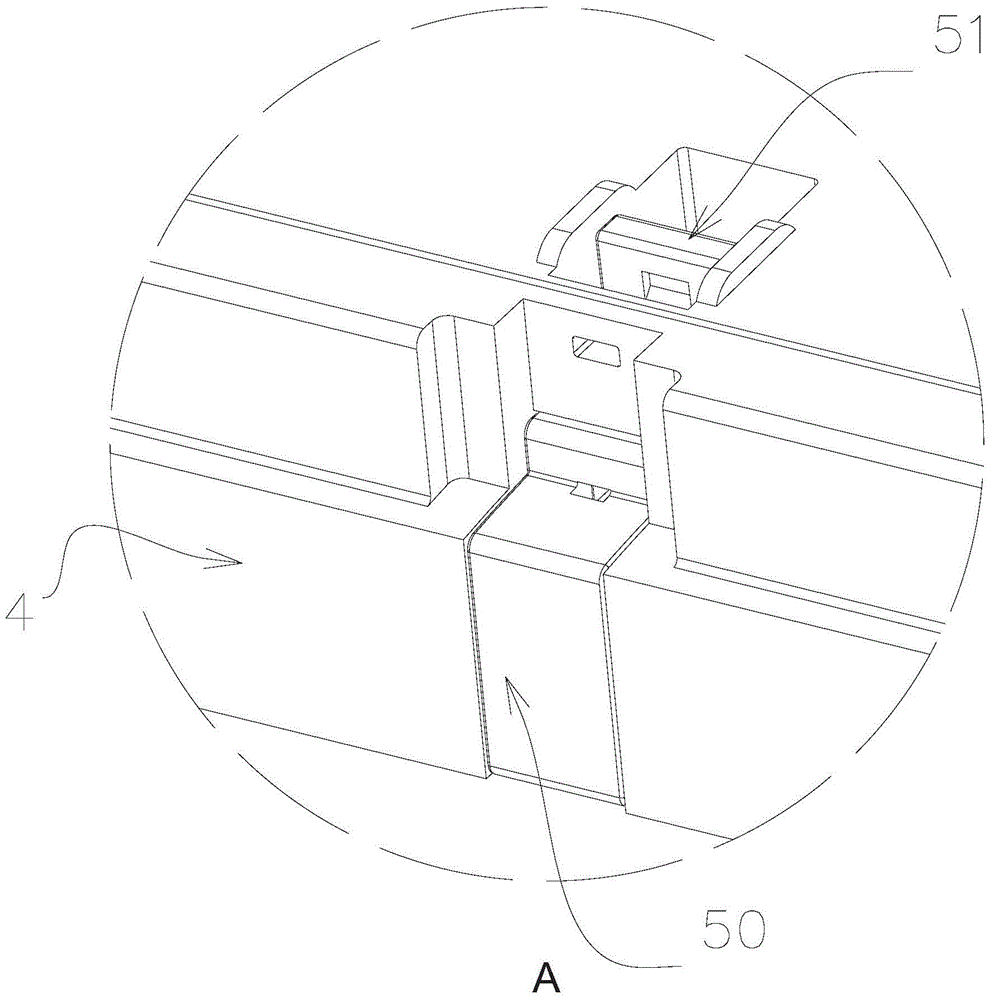

[0059] Such as Figure 1-16 As shown, the container 100 of this embodiment includes a base 1, a pair of opposite side plates 2 and a pair of opposite side plates 3, and an upper cover 4. The locking mechanism 5 includes a locking member 50, a driving member 51, and a locking member 51 formed on the side plates. Side plate structure 52, spring 53 and the upper cover structure 54 formed on the upper cover, locking member 50 and driver 51 are all installed in the upper cover structure 54, when upper cover 4 is installed on the side plate 2, the side plate structure 52 receives a part of the locking member 50 so as to lock the upper cover 4 on the side panel 2 .

[0060] figure 1 It is a three-dimensional view of the container of the present invention. Such as figure 1 As shown, the container 100 includes a base 1 , a pair of opposite side panels 2 , a pair of opposite side panels 3 , and an upper cover 4 . A locking mechanism 5 is provided between the upper cover 4 and the si...

Embodiment 2

[0081] In this embodiment, the parts that are not described in detail are the same as those in Embodiment 1.

[0082] Such as Figures 16-23 As shown, the difference between this embodiment and Embodiment 1 is mainly that the driving member is used to drive the locking member 50 to move through the rotational movement of the driving member.

[0083] Such as Figure 20-22 As shown, the upper cover structure 54 on the upper cover 4 includes a surface portion 54B disposed on the upper surface of the upper cover and a side portion 542 disposed on a side portion of the upper cover. In this embodiment, the side portion 542 of the upper cover is the same as that of Embodiment 1, and will not be described in detail here.

[0084] Such as Figures 16-19 As shown, the surface portion 54B includes a groove 54B1, a rotating shaft 54B2, a rotating shaft hanging platform 54B3, and a hanging platform 54B4. Wherein, the rotating shaft 54B2 is disposed in the groove 54B1, the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com