Novel conveying pipeline

A pipeline, a new type of technology, applied in the field of new transmission pipelines, can solve the problems of weak mobility, narrow application range, difficult to change, etc., and achieve the effect of strong reliability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

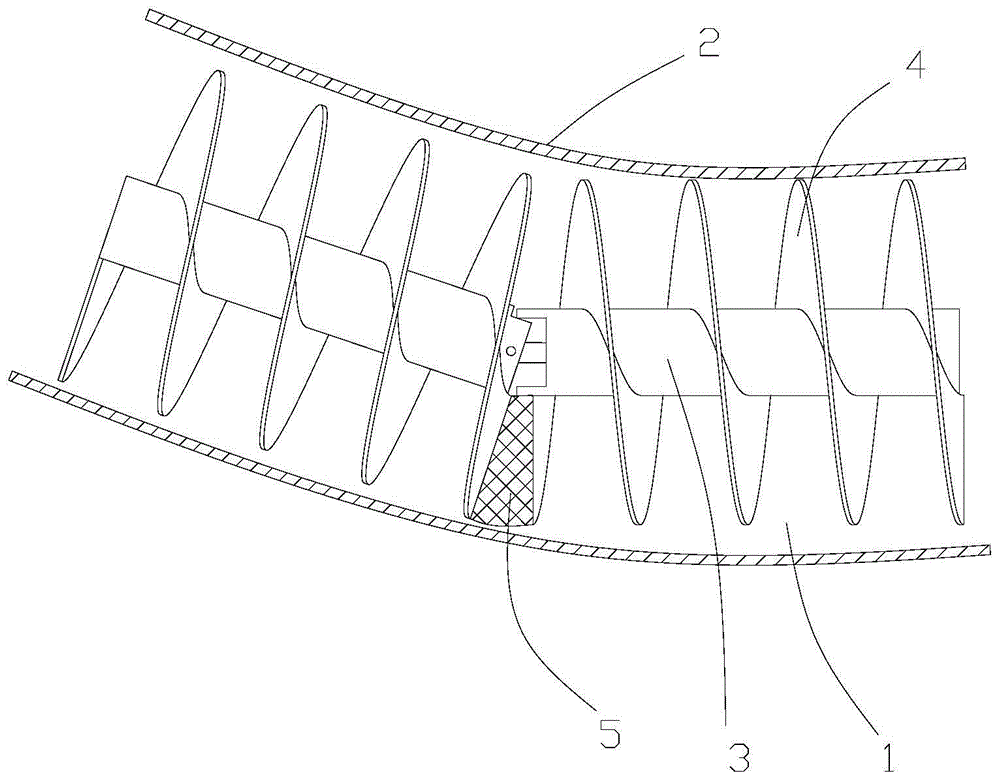

[0028] see figure 1 , this embodiment discloses a new pipeline for transmission, including a pipeline 2, a helical blade rotor core and a motor; the helical blade rotor core is composed of at least one helical blade unit 1 connected, and the helical blade unit 1 includes a central shaft 3 located at the center , the helical blade 4 around the periphery of the central shaft 3, and the universal joint joints located at both ends of the central shaft 3; the two adjacent helical blade units 1 are connected together through the universal joint joint transmission, and the two universal joints The joint joints are combined into a universal joint; the helical blade rotor core is penetrated inside the pipeline 2 and extends along the extension direction of the pipeline 2; the end of the helical blade rotor core is connected with the motor drive.

[0029] Traditional conveying equipment such as conveyor belts can only be used for straight-line conveyance of goods, and the structure of e...

Embodiment 2

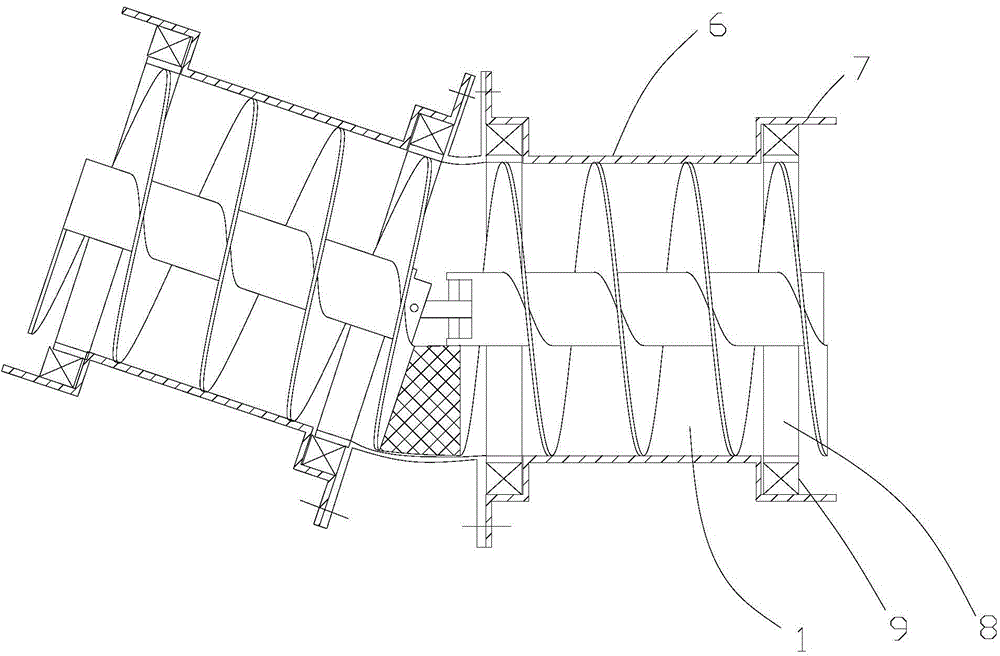

[0040] see figure 2 , The difference between this embodiment and Embodiment 1 is that: on the basis of the solution of Embodiment 1, a bearing 9 is added to increase the stability of the operation of the device. For light load occasions or when the extension length between the pipe 2 and the helical blade rotor core is not long, the running resistance between the helical blade rotor core and the pipe 2 is not large, but in a heavy-load environment, the helical blade rotor core and the pipe 2 The running resistance between them is greatly increased, even if a high-torque motor is used, it may not be able to smoothly promote the rotation of the spiral blade core.

[0041] The technical solutions that can be applied to heavy-duty environments are introduced in detail below:

[0042]Preferably, the helical blades 4 at both ends of the helical blade unit 1 are rigidly connected with an annular bearing connecting portion 8, the inner wall of the bearing connecting portion 8 is flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com