Chrome sand sorter

A technology of selecting machine and chrome sand, applied in foundry sand and foundry field, can solve the problems of general selection effect, high price and complexity, and achieve the effect of good selection effect, high recovery rate and correct design route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

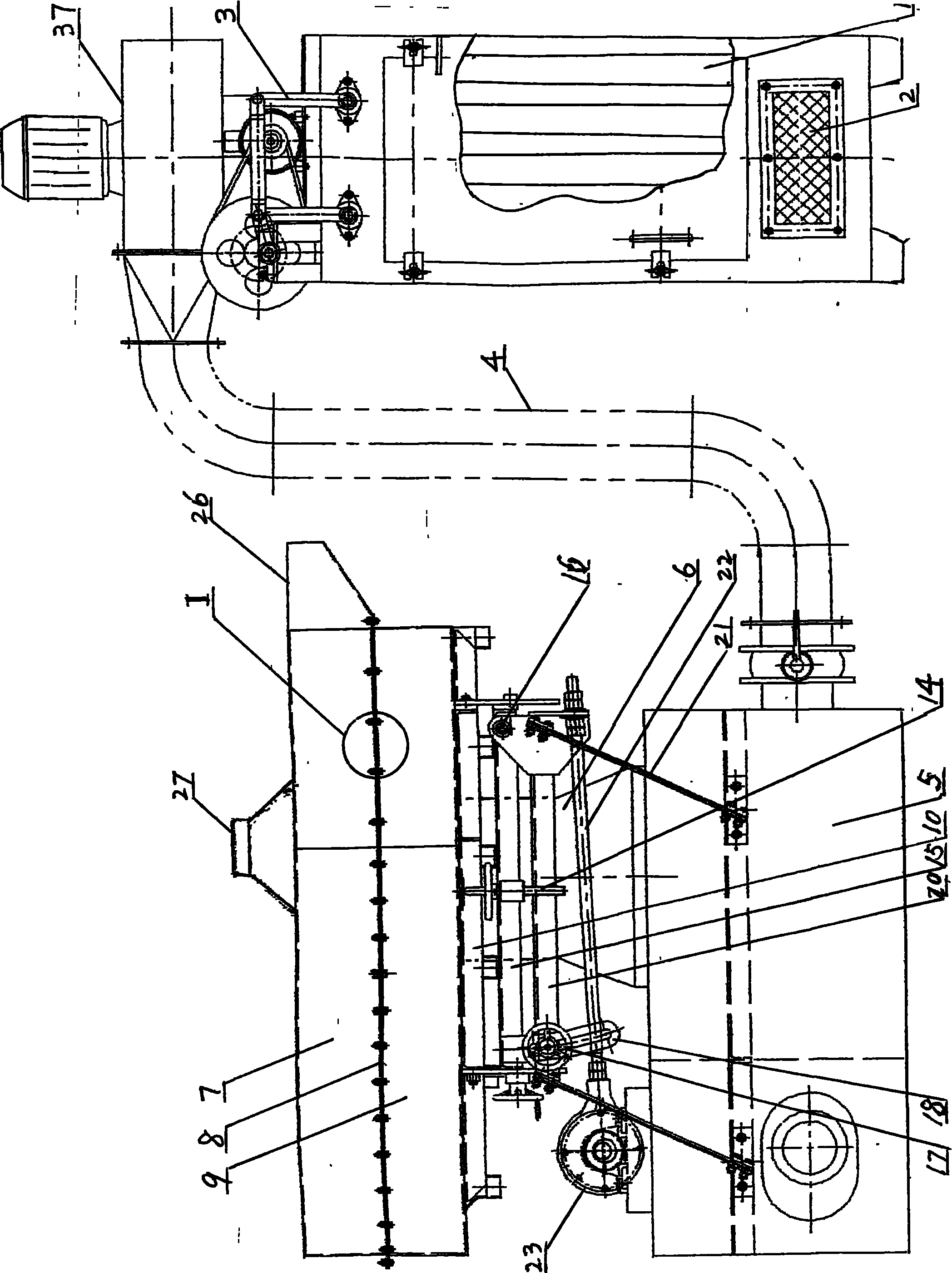

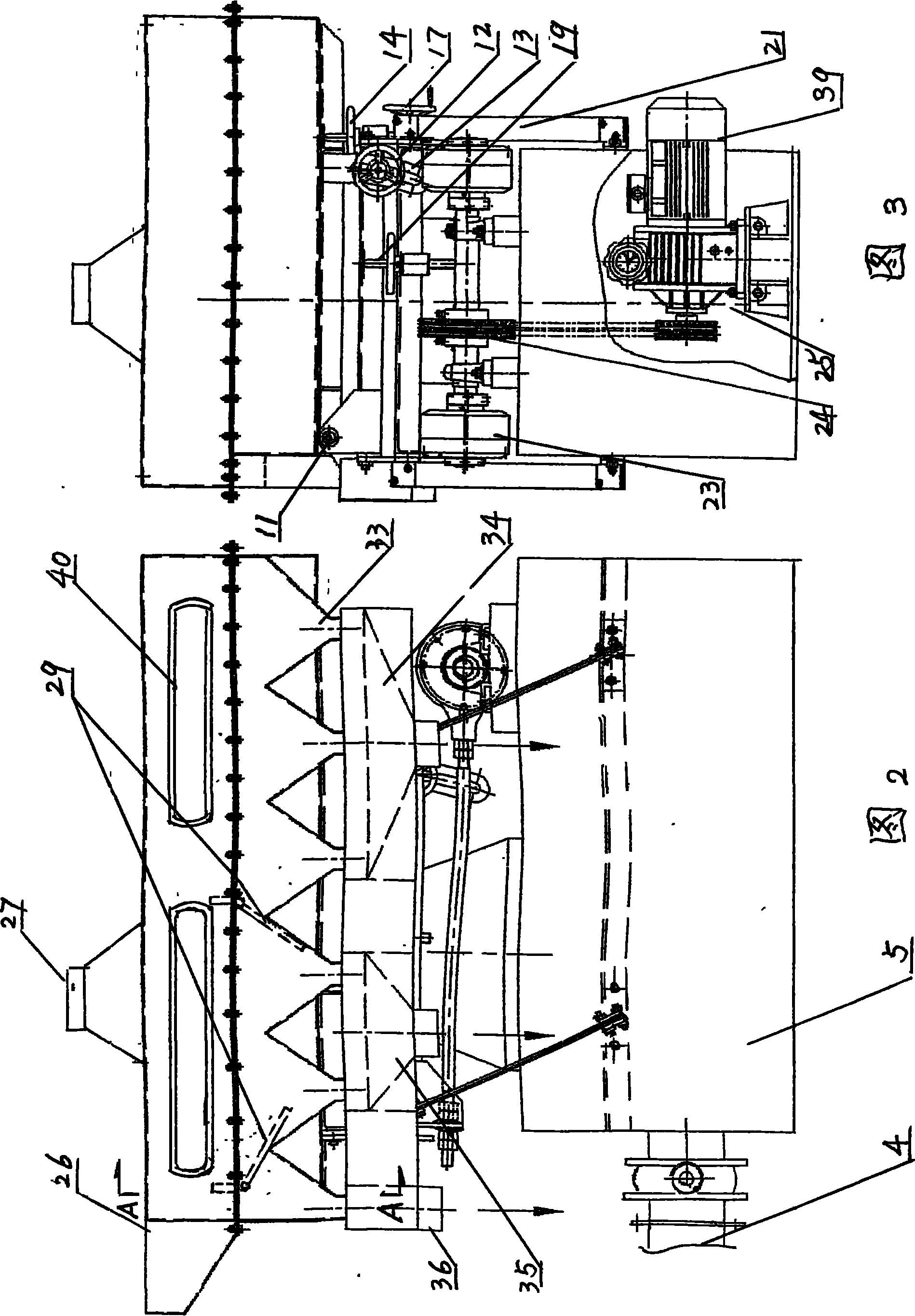

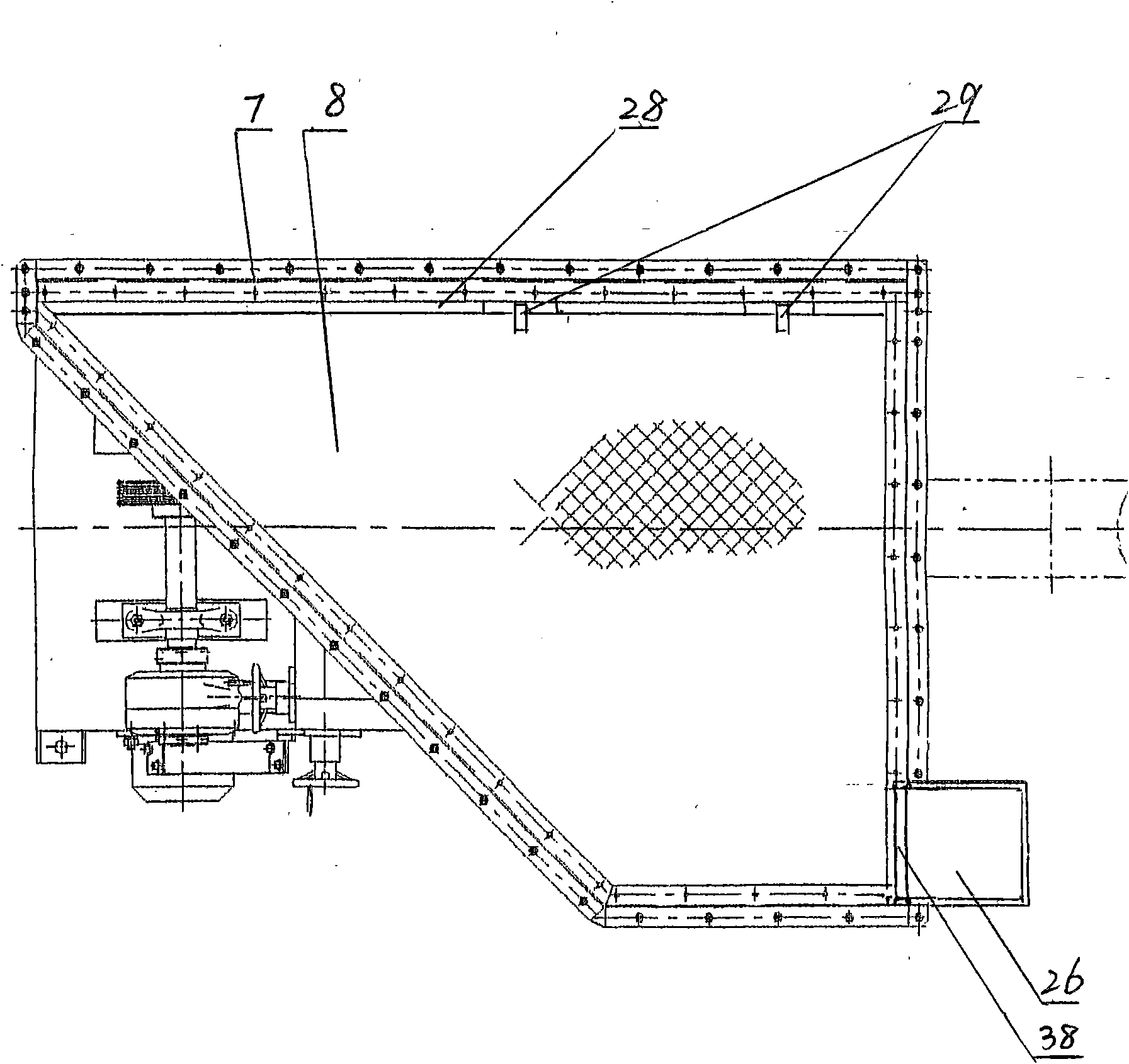

[0017] attached figure 1 , 2 , 3, and 4 provide a specific embodiment of the present invention, and the structure of the selection machine will be described in more detail below in conjunction with the above-mentioned accompanying drawings. The chrome sand concentrator consists of three parts: air blowing device, sorting sieve connected through air duct, and sorting sieve with vibrating mechanism. The sorting screen includes a screen box 7, a screen 8 is fixed in the middle, and an air distribution chamber 9 is located under the screen. The bottom of the air distribution chamber 9 is provided with an air inlet hole connected to the air inlet hose 6, and the air inlet hose 6 and the other The other end is connected to the wind storage cabinet 5, and the wind storage cabinet is connected to the blast device through the air delivery pipe 4. The sieve box 7 looks like a triangle when viewed from above, and its front end is provided with a feed port 26, and the feed port is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com