Method for removing metal impurities in organosilicon compounds

A technology of organosilicon compounds and metal impurities, which is applied in the direction of silicon organic compounds, etc., to achieve the effect of simplifying operations and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

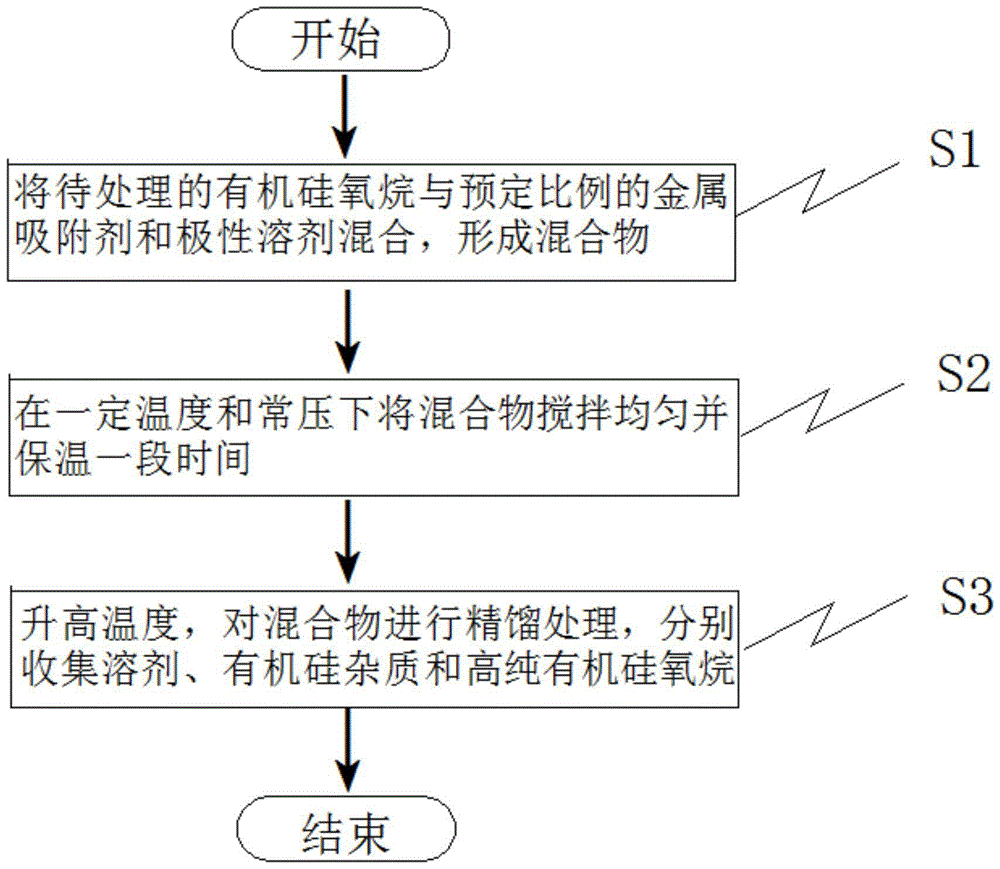

Method used

Image

Examples

Embodiment 1

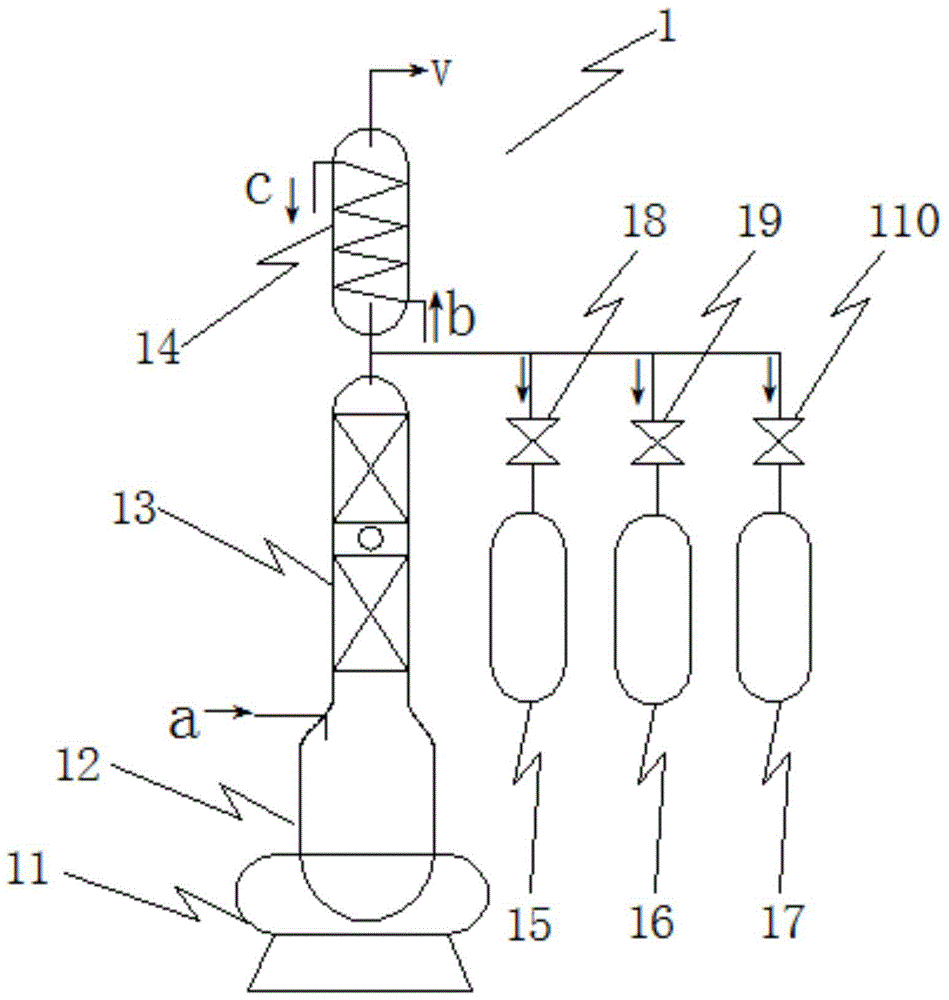

[0045]Provide industrial grade octamethylcyclotetrasiloxane (purity 98.0%), the main organosilicon impurities are hexamethylcyclotrisiloxane, etc., and the total metal ion content is 6.5ppm. 2000g of industrial grade octamethylcyclotetrasiloxane, 1000g of isopropanol and 10g of silica gel SiliaMets TAAcONa were added to the rectification kettle 12, and stirred at normal temperature and pressure for 3h. Vacuumize to a vacuum degree of 20KPa, raise the temperature of the magnetic stirring heater to 50°C, and collect the fraction at the top of the tower at 30-50°C in the receiving bottle 15 . After no fraction flows out, the temperature of the magnetic stirring heater is raised to 150° C., and the 80-105° C. fraction at the top of the tower is collected in the receiving bottle 16 . After the temperature of the overhead fraction is stabilized at 106° C., the fraction at the top of the tower at 106° C. is collected in the receiving bottle 17 . Sampling analysis shows that the puri...

Embodiment 2

[0047] Provide industrial grade trifluoropropylcyclotrisiloxane (purity 98.5%), the main organosilicon impurities are high boiling point organosiloxane, etc., and the total metal ion content is 3.2ppm. Add 1500g of technical grade trifluoropropylcyclotrisiloxane, 800g of acetone and 8g of activated carbon into the rectification kettle 12, raise the temperature of the magnetic stirring heater to 40°C under normal pressure and stir for 3h. The temperature of the magnetic stirring heater was raised to 70° C., and the 50-60° C. distillate at the top of the tower was collected in the receiving bottle 15 . After no fraction flows out, vacuumize to a vacuum degree of 4.5KPa, raise the temperature of the magnetic stirring heater to 160° C., and collect the fraction at 60-136° C. at the top of the tower in the receiving bottle 16 . After the temperature of the overhead fraction is stabilized at 137° C., the fraction at the top of the tower at 137° C. is collected in the receiving bottl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com