A kind of large and micro double-hole carbon film material and preparation method thereof

A technology of thin-film carbon and composite materials, which is applied in the field of material chemistry, can solve the problems of cumbersome carbonization pore expansion procedures, difficult removal of template agents, and easy collapse of morphology, and achieve the goals of green, energy-saving and environmental protection in the process, simple preparation methods, and great application potential. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a large and micro double-hole thin film carbon material, comprising the following steps:

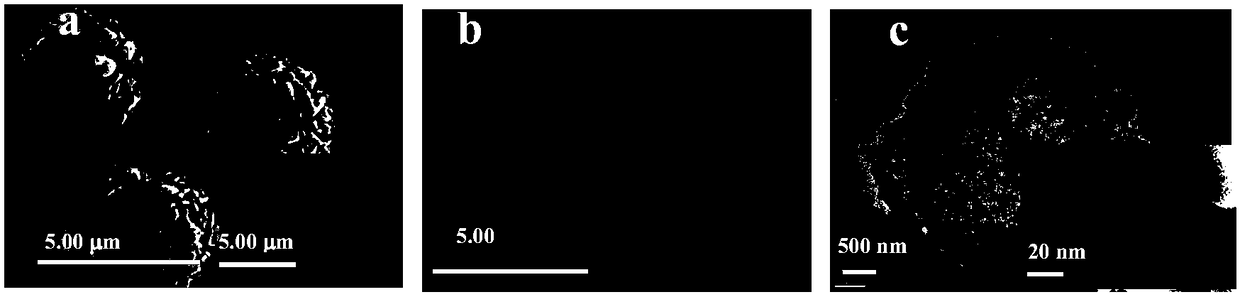

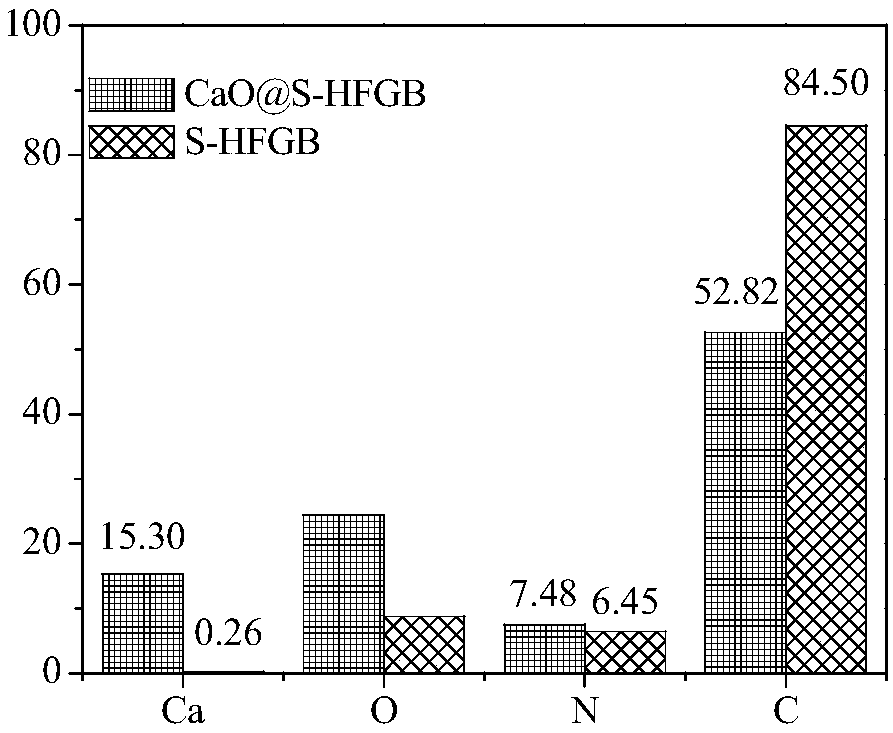

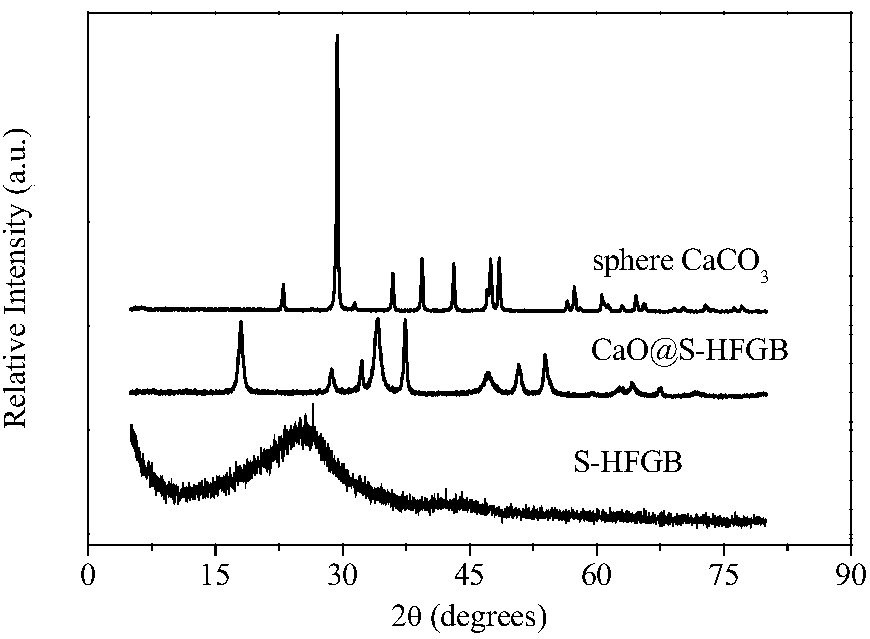

[0041] (1) Synthesis of hollow spherical calcium carbonate

[0042] Prepare concentration 20g·L respectively -1 Polyvinylpyrrolidone (PVP) aqueous solution 600mL, concentration 0.1mol L -1 Calcium Chloride (CaCl 2 ) aqueous solution 800mL, concentration 0.1mol L -1 of sodium carbonate (Na 2 CO 3 ) 800mL aqueous solution and a concentration of 0.05mol L -1 600mL of sodium dodecylsulfonate (SDS) aqueous solution, four different solutions were sealed and stirred evenly; two parts (300mL each) of the prepared PVP solution were added to the prepared CaCl 2 solution and Na 2 CO3 In the solution, under the condition of 20℃ water bath, stir vigorously for 0.5h; then add the prepared SDS solution to the above Na 2 CO 3 solution, stirred vigorously for 0.5h; the above CaCl 2 Add Na to the solution 2 CO 3 In the mixed solution, the temperature of the water ...

Embodiment 2

[0048] Except following change, all the other are the same as embodiment 1.

[0049] The preparation concentration is 3g·L -1 Dopamine salt (DA) aqueous solution 100mL, concentration 8g·L -1 Hollow spherical calcium carbonate aqueous solution 50mL, that is, the weight ratio is 0.75DA / 1.0CaCO 3 dopamine salt and hollow spherical calcium carbonate, and a weakly alkaline solution prepared by 0.75mL ammonia water, 40mL ethanol, and 90mL deionized water. The three different solutions were sealed and stirred evenly; the prepared calcium carbonate aqueous solution was added to the dopamine salt solution In water bath temperature 15°C, stirring speed 150r·min -1 Under the condition of 0.5h, the prepared weak alkaline solution was added to the dopamine salt mixed solution, the reaction temperature and rotation speed were kept constant, and the intermediate product CaCO was obtained after 20h reaction. 3 @PDA;

[0050] Weigh a certain mass of CaCO 3 The @PDA sample is placed in a t...

Embodiment 3

[0052] Except following change, all the other are the same as embodiment 1.

[0053] The preparation concentration is 6g·L -1 Dopamine salt (DA) aqueous solution 100mL, concentration 8g·L -1 Hollow spherical calcium carbonate aqueous solution 50mL, that is, the weight ratio is 1.5DA / 1.0CaCO 3 dopamine salt and hollow spherical calcium carbonate, and a weakly alkaline solution prepared by 0.75mL ammonia water, 40mL ethanol, and 90mL deionized water. The three different solutions were sealed and stirred evenly; the prepared calcium carbonate aqueous solution was added to the dopamine salt solution In the water bath temperature 25 ℃, stirring speed 300r min -1 Under the condition of 0.5h, the prepared weak alkaline solution was added to the dopamine salt mixed solution, the reaction temperature and rotation speed were kept constant, and the intermediate product CaCO was obtained after 20h reaction. 3 @PDA;

[0054] Weigh a certain mass of CaCO 3 The @PDA sample is placed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com