ZIF-based nitrogen-doped porous carbon material and preparation method thereof

A nitrogen-doped porous carbon and calcium carbonate technology, applied in the field of material chemistry, can solve the problems of polluting pore expanders, template agents that are difficult to remove, and easy to collapse in morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of ZIF-based nitrogen-doped porous carbon material, comprising the following steps:

[0046] (1) Configure 0.4mol·L respectively -1 Calcium Chloride (CaCl 2 ) aqueous solution 490mL, 0.4mol L -1 of sodium carbonate (Na 2 CO 3 ) aqueous solution 490mL, 2g L -1 Polyvinylpyrrolidone (PVP) aqueous solution 20mL. Under the temperature condition of 35°C, the three solutions were sealed and stirred evenly; the polyvinylpyrrolidone (PVP) solution was evenly divided into two parts (10mL), and respectively added to CaCl 2 solution and Na 2 CO 3 In the solution, keep stirring in a water bath at 35°C for 30 minutes to make it fully stirred evenly; add CaCl 2 The solution was quickly poured into vigorously stirred Na 2 CO 3 In solution at 600r·min -1 Under the condition of a certain stirring speed, the slurry after the reaction was suction-filtered, washed with absolute ethanol and deionized water, the above operation was repeated three times, and vac...

Embodiment 2

[0055] A preparation method of ZIF-based nitrogen-doped porous carbon material, comprising the following steps:

[0056] Except following change, all the other are the same as embodiment 1. Add 0.1 g zinc nitrate hexahydrate crystals to CaCO 3 @PDA solution, stirred at room temperature for 1 h. Add 0.3 mL of triethylamine to the dimethylimidazole solution, and stir at room temperature for 30 min. The well-mixed dimethylimidazole solution was added dropwise to the CaCO 3 @PDA solution, at room temperature at 550r·min -1 The conditions were stirred for 1h. After the reaction, the slurry was suction filtered, washed with ethanol, and dried under vacuum at 80°C for 5 hours to obtain CaCO 3 @PDA @ZIF-8 composite. Weigh a certain mass of CaCO 3 The @PDA@ZIF-8 sample is placed in a tube furnace and subjected to high-temperature carbonization under the protection of nitrogen. The carbonization conditions are: 5°C min -1 The rate at which CaCO 3 The @PDA@ZIF-8 sample was raise...

Embodiment 3

[0058] A preparation method of ZIF-based nitrogen-doped porous carbon material, comprising the following steps:

[0059] Except following change, all the other are the same as embodiment 2. Weigh a certain mass of CaCO 3 The @PDA sample is placed in a tube furnace and subjected to high-temperature carbonization under the protection of nitrogen. The carbonization conditions are: 5°C min -1 The rate at which CaCO 3 The @PDA@ZIF-8 sample was raised from room temperature to 900 °C, kept at a constant temperature for 2 hours, and then naturally cooled to room temperature. The intermediate product CaO@S-NGPC-ZIF-8 was obtained, which was washed to neutrality with deionized water (the washing procedure was the same as

[0060] Example 1), the ZIF-based nitrogen-doped porous carbon material S-NGPC-ZIF-8 was finally obtained.

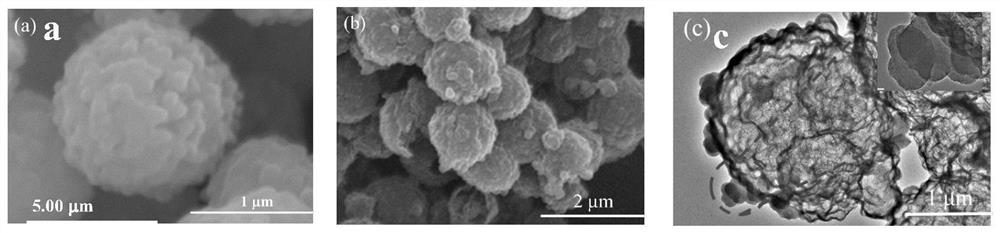

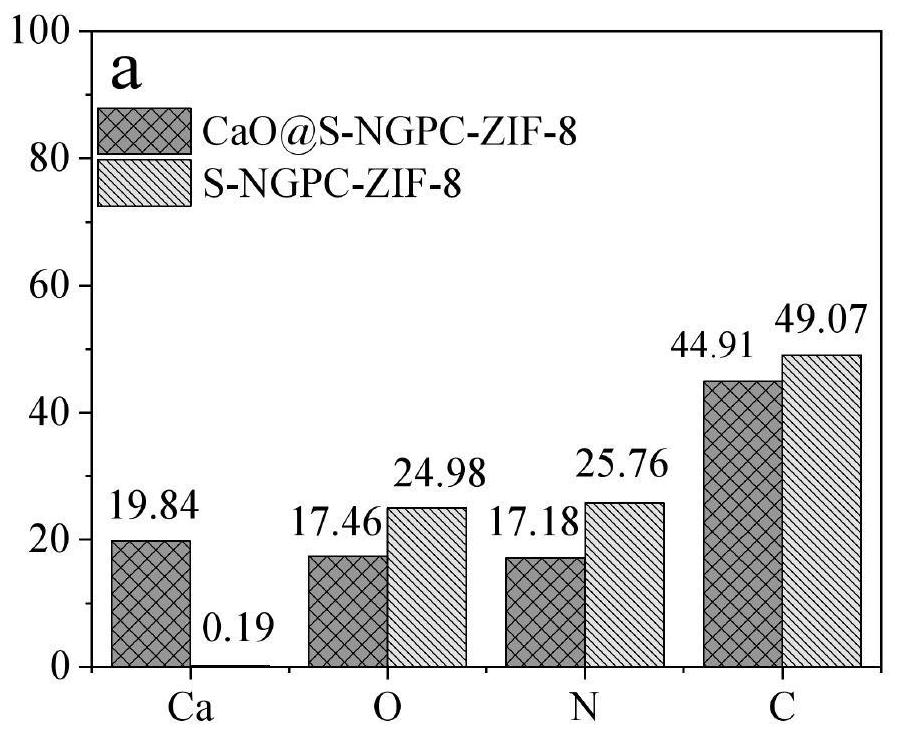

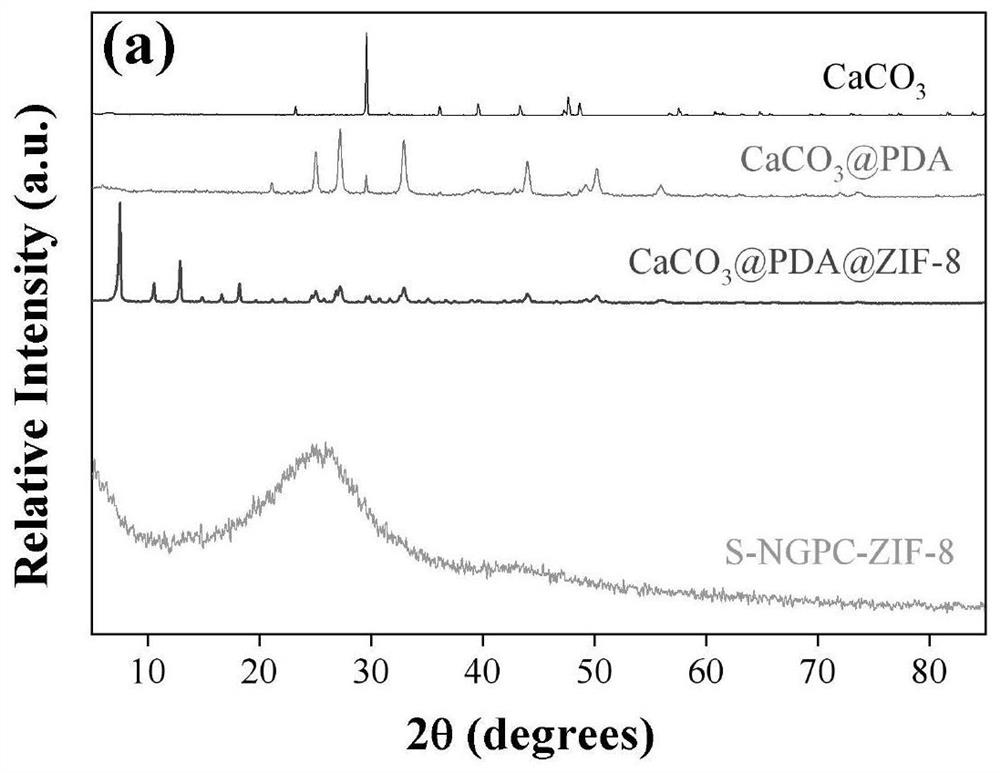

[0061] Case Analysis

[0062] Such as figure 1 As shown, the nitrogen-doped porous carbon material S-NGPC-ZIF-8 prepared in Example 1 of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com