Heat dissipation structure

A technology of heat dissipation structure and heat dissipation holes, which is applied in the field of computer applications and can solve problems such as difficult removal of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

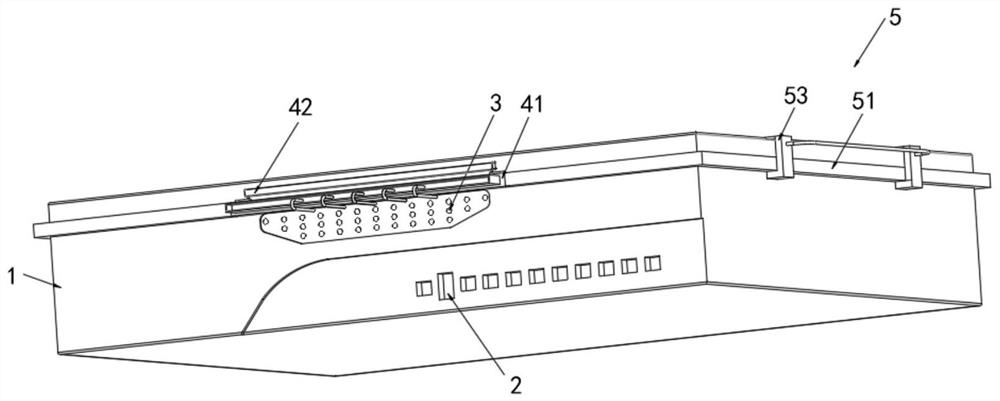

[0047] Computer network vulnerability investigation protection device, refer to Figure 1 to Figure 7 , including a housing 1, the housing 1 is provided with an interface 2, the upper part of the front side of the housing 1 is uniformly provided with cooling holes 3, and the front side of the housing 1 is provided with a driving assembly 4 on the upper part of the cooling holes 3, the driving assembly 4 Push out the dust in the cooling hole 3 through its own matching column 472, both sides of the driving component 4 are in contact with the fixing component 5, and the fixing component 5 is in contact with the outer wall of the housing 1, the fixing component 5 can assist the cooling hole 3 The heat on the housing 1 is dissipated.

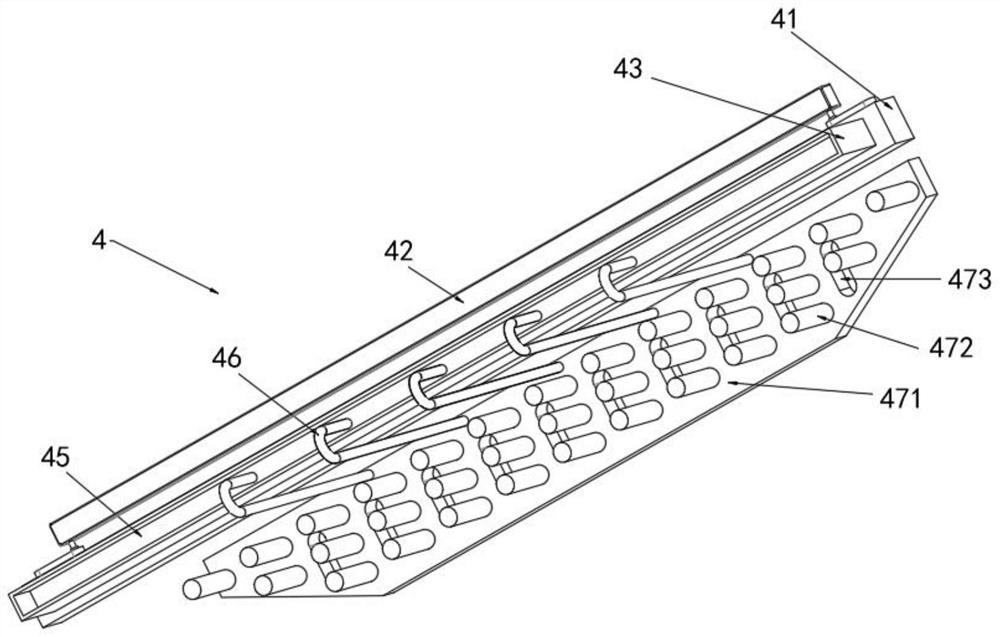

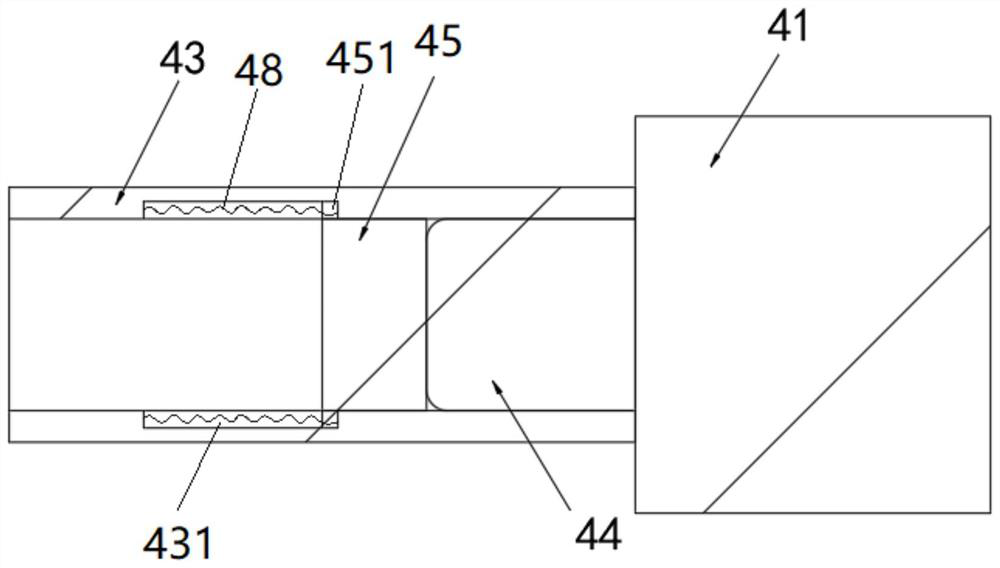

[0048] The drive assembly 4 includes a heat transfer rod 41 fixedly connected to the front side of the housing 1. Both the heat transfer rod 41 and the heat transfer frame 51 are made of copper-aluminum alloy. The top of the heat transfer rod 41 is p...

Embodiment 2

[0055] see figure 2 and Figure 5 The connection plate body 471 is evenly provided with ventilation holes 473, and by setting the ventilation holes 473 on the connection plate body 471 without affecting the installation of the matching column 472, when the connection plate body 471 is not in use, the hot air inside the housing 1 can pass through The ventilation hole 473 flows into the heat dissipation hole 3 so as to improve heat dissipation efficiency.

[0056] All the other structures are the same as in Example 1.

[0057] From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects:

[0058] The heat dissipation structure of the present invention includes a housing 1, on which the heat dissipation holes 3 are arranged; a moving part 45, which is arranged outside the housing 1; a matching column 472, which is arranged inside the housing 1, The matching column 472 is used to be inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com