Water conservancy gate device capable of being locked automatically

An automatic locking and water conservancy technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as gate plate drop, reliability and low degree of automation, and adverse effects on the stability of the screw gate system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

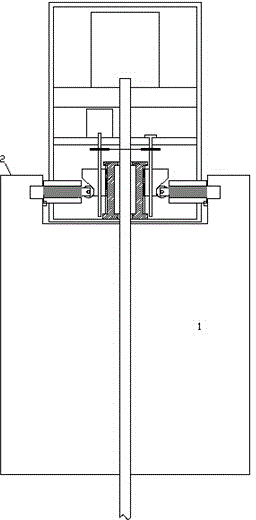

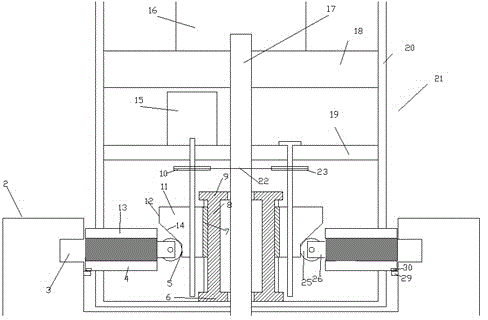

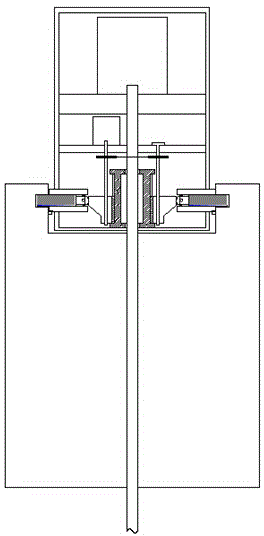

[0016] according to Figure 1-4 , the present invention will be described in detail.

[0017] A water conservancy gate device capable of automatic locking, comprising a gate plate 1 and a gate plate lifting drive device 21, the gate plate lifting drive device 21 includes a housing 20, the housing 20 is fixed to a supporting base, and the housing 20 There are upper fixing ribs 18, middle fixing ribs 19 and a bottom fixing surface in the inside, and the upper fixing ribs 18 are supported with a gate plate lift drive motor 16, and the gate plate lift drive motor 16 is connected with the gate plate lift drive screw rod 17. The upper end is power-connected, the gate plate lifting driving screw 17 passes through the upper fixing rib 18, the middle fixing rib 19 and the through hole in the bottom fixing surface, and the gate plate lifting driving screw 17 is connected with the gate plate The screw holes in 1 are screwed together; the two sides of the upper edge of the gate plate 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com