A device and method for simulating complex fracture sanding in shale

A complex, laying technology, applied to flow and laying devices, simulates the migration of proppant in complex fractures, and can solve the problem of fracturing fluid filtration without considering the rough surface of the fracture wall, and the hole diameter, phase and phase of the wellbore perforation. Density, inability to study the law of sand bank accumulation and laying, and determination of indoor simulation parameters, etc., to achieve the effects of large scale, prolonging oil well life, and increasing oil and gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

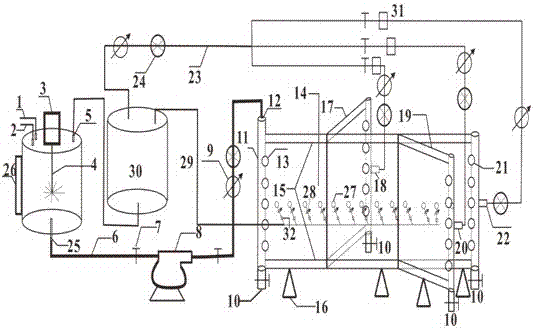

[0031] Further illustrate the present invention below in conjunction with accompanying drawing:

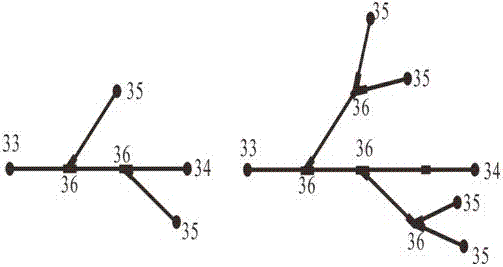

[0032] see figure 1 and figure 2, the experimental device for simulating proppant laying in fractures includes complex artificial fracturing fractures, which can simulate two different fracture shapes, and the complex artificial fractures include primary fractures and secondary fractures17,19 And 36, the two sidewalls of the main and secondary cracks are made up of transparent plexiglass flat plates 14 arranged parallel to each other, and the upper and lower ends of the two transparent plexiglass flat plates are respectively sealed by a frame 15, and at the left end of the main crack transparent plexiglass flat plates A vertical simulated well shaft 11 is set, and respective liquid outlet pipes 18, 20 and 22 are arranged at the right end of the main fracture and the secondary fracture, and the transparent plexiglass plate, the frame, the cylinder wall of the simulated well shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com