Explosion-proof method of LNG (liquefied natural gas) filling machine

A filling machine and air compressor technology, applied in the container discharge method, container filling method, mechanical equipment, etc., can solve the problems of increasing the cost of the filling machine, electric spark explosion, affecting the promotion of the filling machine, etc., and achieve reduction Explosion-proof requirements, simple explosion-proof methods, and obvious explosion-proof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples.

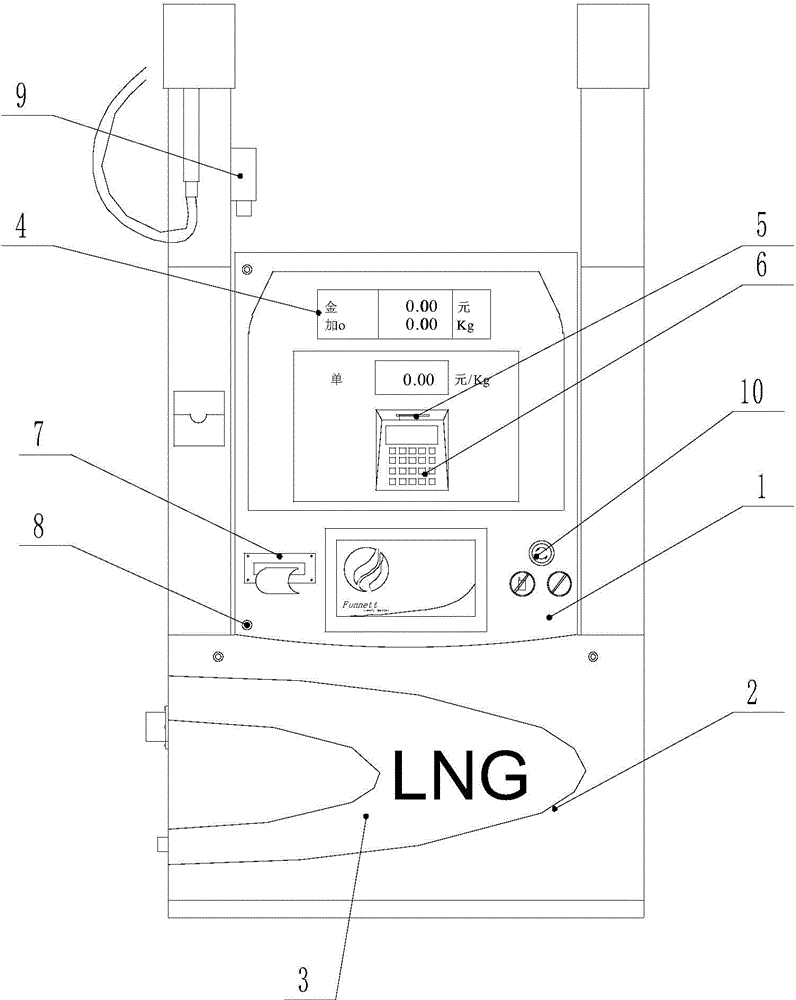

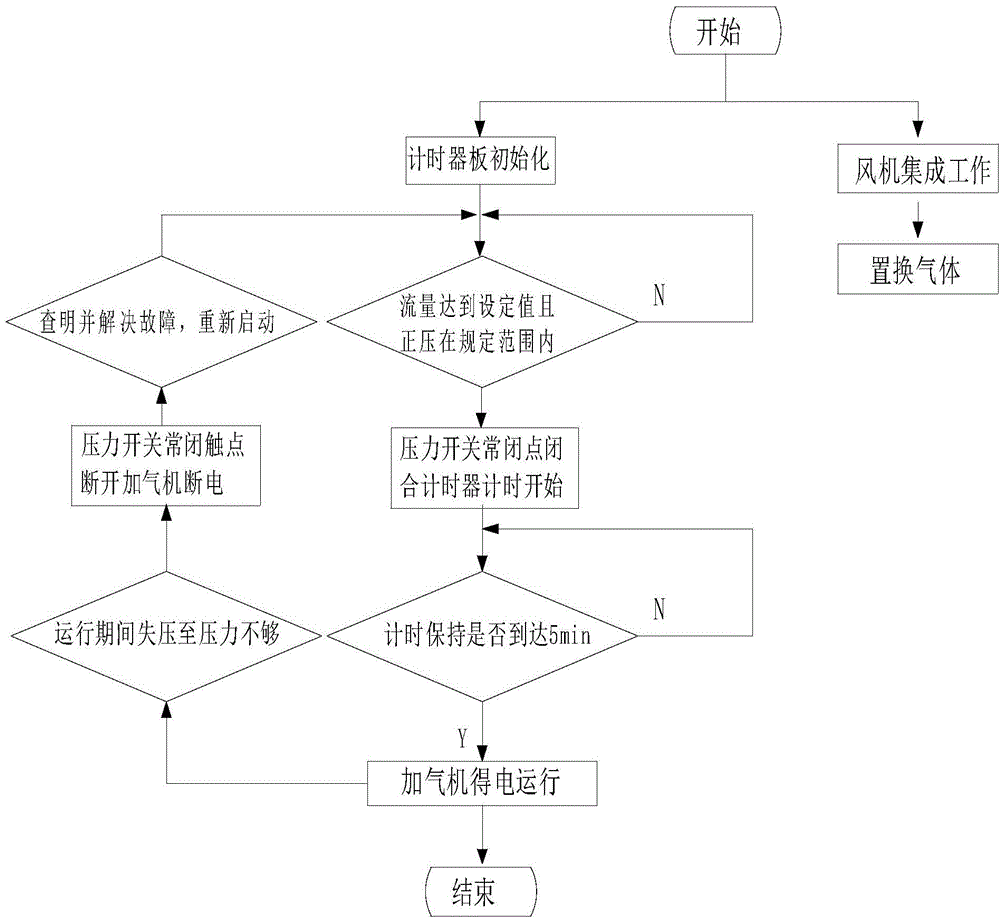

[0022] Such as figure 1 , 2 As shown, an explosion-proof method for an LNG filling machine, including:

[0023] A. Provide a LNG filling machine, the conductive part of the filling machine is installed in the first chamber 1, the liquid supply part 3 of the filling machine is installed in the second chamber 2, the first chamber 1 and The second chambers 2 are communicated by through holes; generally speaking, the first chamber 1 is on the top and the second chamber 2 is on the bottom, and the through holes are used for wiring and also as air flow holes.

[0024] B. Provide a gas source that can continuously supply safe gas. The gas source communicates with the first chamber 1. The gas source continuously provides safe gas to the first chamber 1, so that the pressure P1 of the first chamber 1 is greater than that of the second chamber. The pressure P2 of chamber 2; there are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com