A kind of purification method of pyrroloquinoline quinone

The technology of a pyrroloquinoline quinone and a purification method is applied in the field of microbial fermentation and pharmacy, which can solve the problems of resin dead adsorption, environmental pollution, and high application cost, and achieve the effects of reducing COD in wastewater, simple purification process, and reducing explosion-proof requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Fermentation liquid is filtered through ceramic membrane, gets 16 parts of gained filtrates, every part of 500ml, is processed to the condition in Table 1 respectively (wherein pH4.5 refers to adjusting pH to be 4.5 with hydrochloric acid, pH4.5-5g / L CaCl 2 Refers to adjusting the pH to 4.5 with hydrochloric acid and then adding calcium chloride, the concentration of calcium chloride is 5g / L, and so on).

[0052] During the process of adjusting the pH and adding calcium chloride, it was found that after standing for a period of time, turbidity appeared in the solution, among which the pH 1.5 was the most obvious. As the pH increased, the turbidity in the solution decreased. Filter the turbid solution, take the clear filtrate for detection, and compare the changes in PQQ units before and after filtration. The filtered clear liquid was used for resin adsorption experiment, 5 ml of polyamide resin was added thereto, and stirred and adsorbed for 1 hour at a room temperature...

Embodiment 2

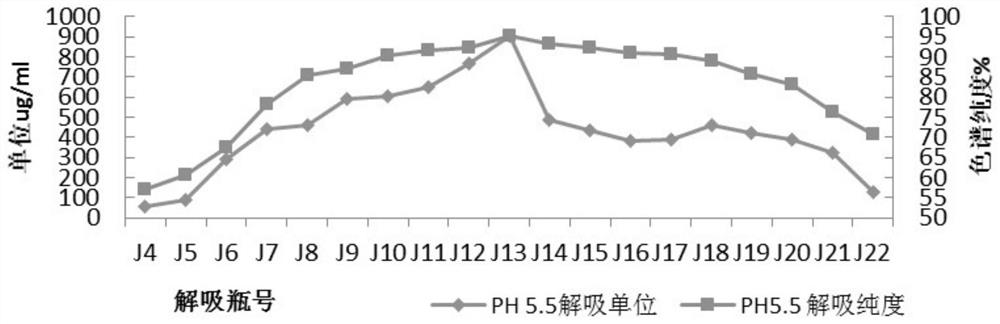

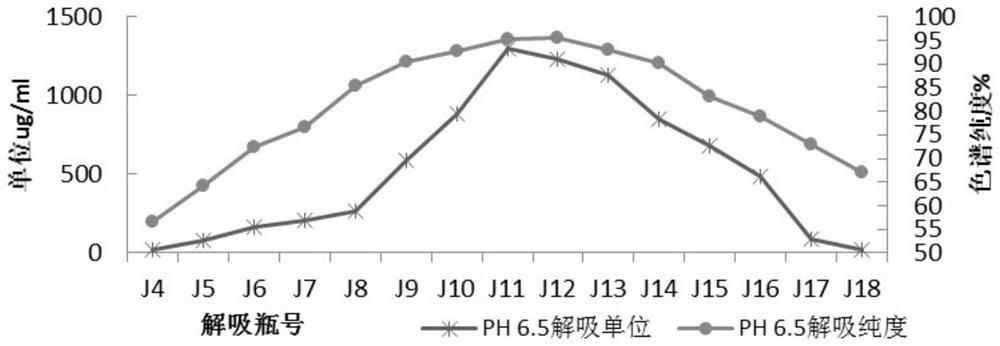

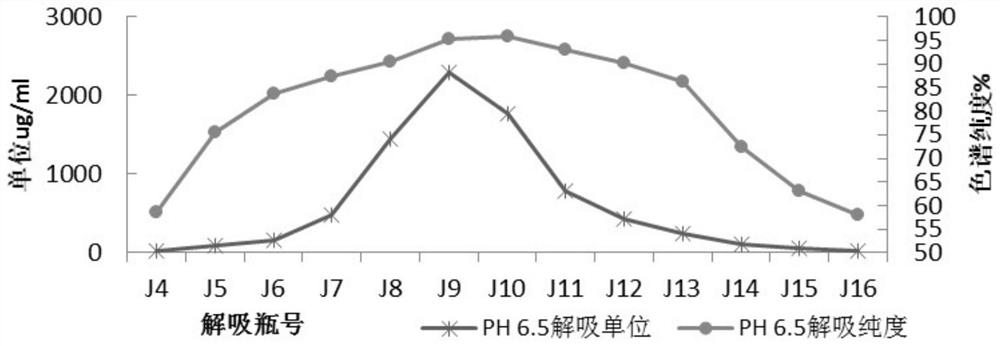

[0058] Take the pretreated new polyamide resin and put it into a 50ml glass chromatography column. After the resin settles, the volume is about 45ml, and 4 columns are packed for use. The fermented liquid was adjusted with hydrochloric acid to a pH of 2.0 after the ceramic membrane filtered filtrate, and 15 g / L calcium acetate was added. After standing for 1 hour, the precipitate was filtered to obtain a clarified upper column liquid. The PQQ chromatographic purity of the upper column liquid was 55.64%. Load the column according to the adsorption capacity of 8.8g / L resin, first wash 2 times the column volume with aqueous hydrochloric acid solution with pH 2.0, then adjust pH 5.5, pH 6.5, pH 7 and pH 6.5 with acetic acid and ammonia water respectively and add 2.5g / L ammonium acetate solution for desorption, the flow rate is 1 times the column volume per hour, 0.5 times the column volume to collect a batch of desorption solution, numbered according to the order of J1, J2, J3.......

Embodiment 3

[0063] This embodiment provides a method for purifying pyrroloquinoline quinone, which specifically includes the following steps:

[0064] (1) 5L of fermented liquid contains PQQ 6.5g, filter with ceramic membrane (aperture 50nm) to obtain 15L of filtrate, adjust the pH to 2.0 with hydrochloric acid, then add 75g of calcium acetate, use a 0.45 micron bactericidal plate to filter and remove the precipitate, and obtain the filtrate containing PQQ 5.8g.

[0065] (2) The polyamide resin with a particle size of 200 to 300 meshes on the filtrate, the column volume is 8.8g / L, and then washed with a hydrochloric acid aqueous solution with a pH of 2.0 for 2 times the column volume, and the leaked liquid is discarded.

[0066] (3) Then use acetic acid and ammonium acetate buffer solution (pH is 6.5, ammonium acetate concentration is 2.5g / L) to carry out desorption, collect the desorption liquid of chromatographic purity ≥ 90%, PQQ content 4.97g.

[0067] (4) Combine the desorption solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com