A shroud-type power distribution terminal electrical assembly grounding device

A technology for power distribution terminals and electrical assembly, applied in the direction of grounding devices, etc., can solve problems such as the impossibility of too large wire diameter, steep increase of wire impedance, and large parasitic inductance, so as to reduce the number of wiring, improve effectiveness, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

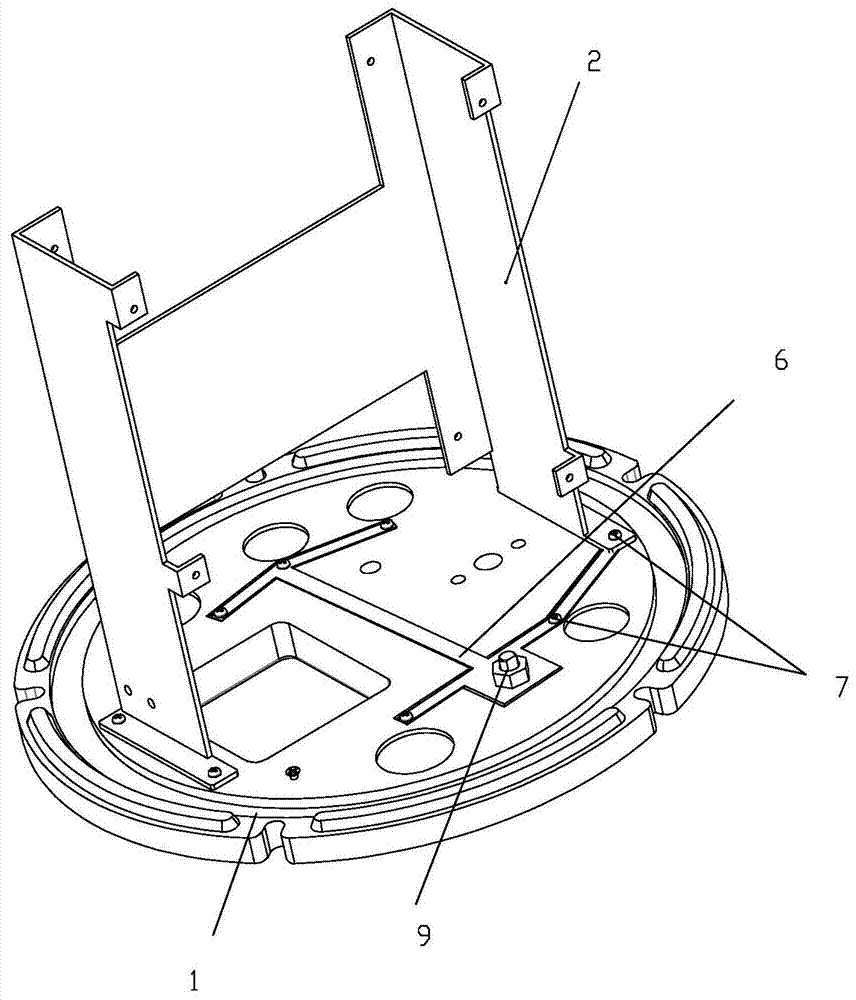

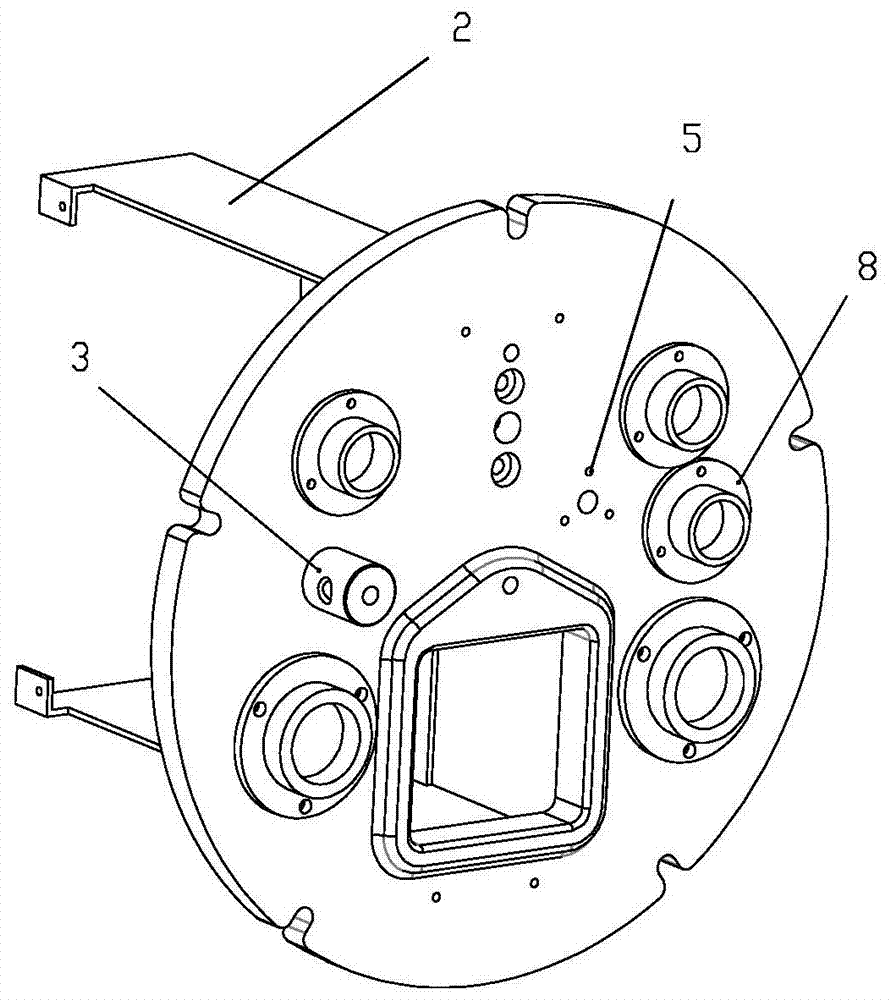

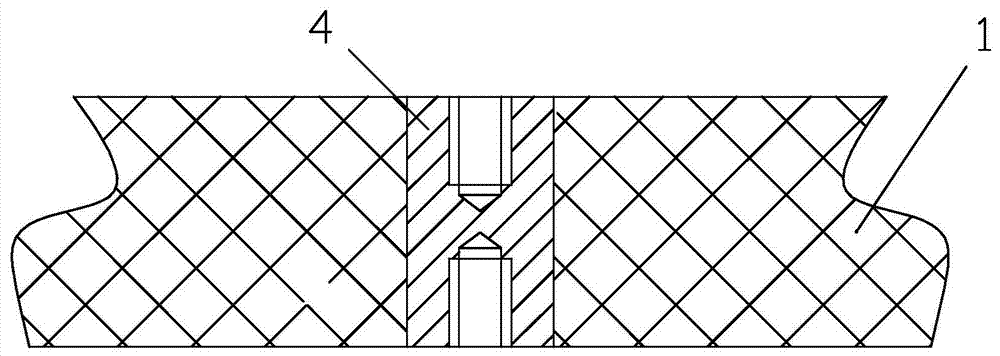

[0017] refer to figure 1 , figure 2 with image 3 , a cover type power distribution terminal electrical assembly grounding device, mainly including a cover plate 1, a bracket 2, a ground plate 6, a ground terminal 3 and an aviation socket 8. The bracket 2 is installed on the cover plate 1, and the cover plate 1 is provided with a mounting hole 5, and a metal piece 4 is embedded in the mounting hole 5, and the ground plate 6 is respectively connected to the metal piece 4 and the metal piece 4 through the connecting piece 7. The bracket 2 is connected, the ground terminal 3 is connected to the ground plate 6 , and the aviation socket 8 is arranged outside the cover plate 1 .

[0018] Preferably, both ends of the metal piece 4 have internal threads, or all the inner surfaces of the metal piece 4 are internal threads;

[0019] In addition, only through holes may be provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com