An integrated ventilated tooth pressure plate

A tooth pressure plate, integrated technology, applied in the field of new integrated ventilation tooth pressure plate, can solve the problems of large welding workload, difficult to ensure smoothness, uneven pressing force, etc., to improve processing quality, flexible air path design, avoid The effect of inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

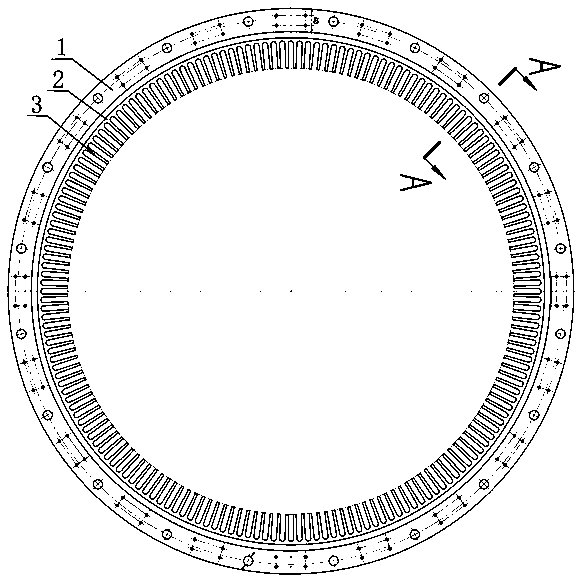

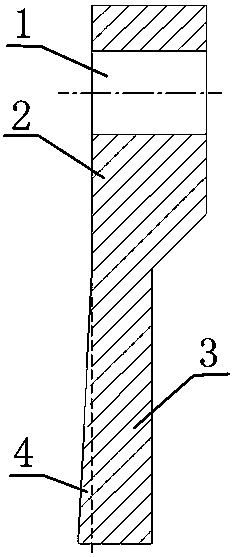

[0017] refer to figure 1 , figure 2 As shown, the present invention discloses an integrated ventilated tooth pressure plate, which includes an annular pressure ring 1 and a tooth pressure plate body 2 made of metal or non-metallic materials. The pressure ring 1 is provided with a plurality of screw mounting holes. The pressure ring 1 and the tooth pressure plate body 2 are an integral structure, wherein the pressure ring 1 is integrally formed as a whole ring, and the tooth pressure plate body 2 is integrally formed or combined in a split fan shape, which can be completed by machining or after casting. After processing, the two end faces and openings of the tooth pressure plate are processed to ensure the dimensional accuracy, so as to ensure an even and tight fit with the iron core. The tooth pressure plate body 2 is provided with a plurality of tooth pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com