An aluminum profile automatic painting device

A technology for automatic painting and aluminum profiles, applied in the direction of spraying devices, spray booths, devices for coating liquid on the surface, etc., to achieve the effect of preventing threats, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

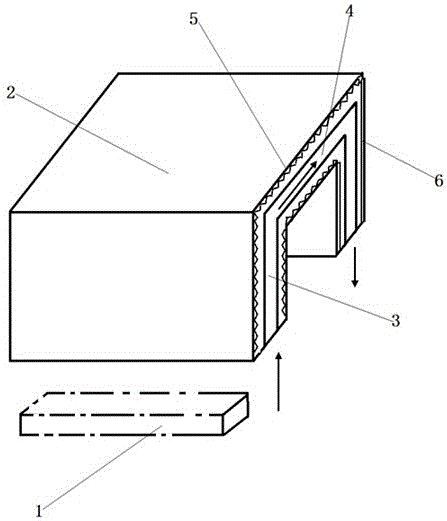

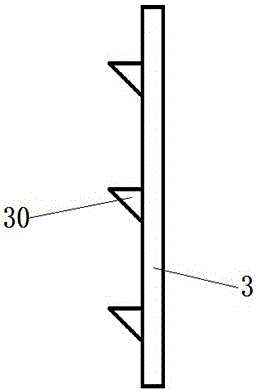

[0014] Example: figure 1 It is a structural schematic diagram of an automatic paint spraying device for aluminum profiles of the present invention; figure 2 It is a longitudinal sectional view of the vertical chute of the present invention; an automatic paint spraying device for aluminum profiles, which is composed of a conveying device, a paint spraying device and a drying device. Groove 3 and horizontal chute 4 are composed, and vertical chute 3 is arranged at both ends of horizontal chute 4, and the limit card 30 that is used for fixing aluminum profile is arranged on described vertical chute 3; The described spray paint The device is made up of a paint spray box 2 and a paint spray hole 5 arranged on the inner surface of the paint spray box 2; the drying device is made up of a heating wire 6 arranged on the inner surface of the paint spray box 2, and the heat generated by the heating wire 6 can be used for the sprayed aluminum Profile 1 is dried.

[0015] The width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com