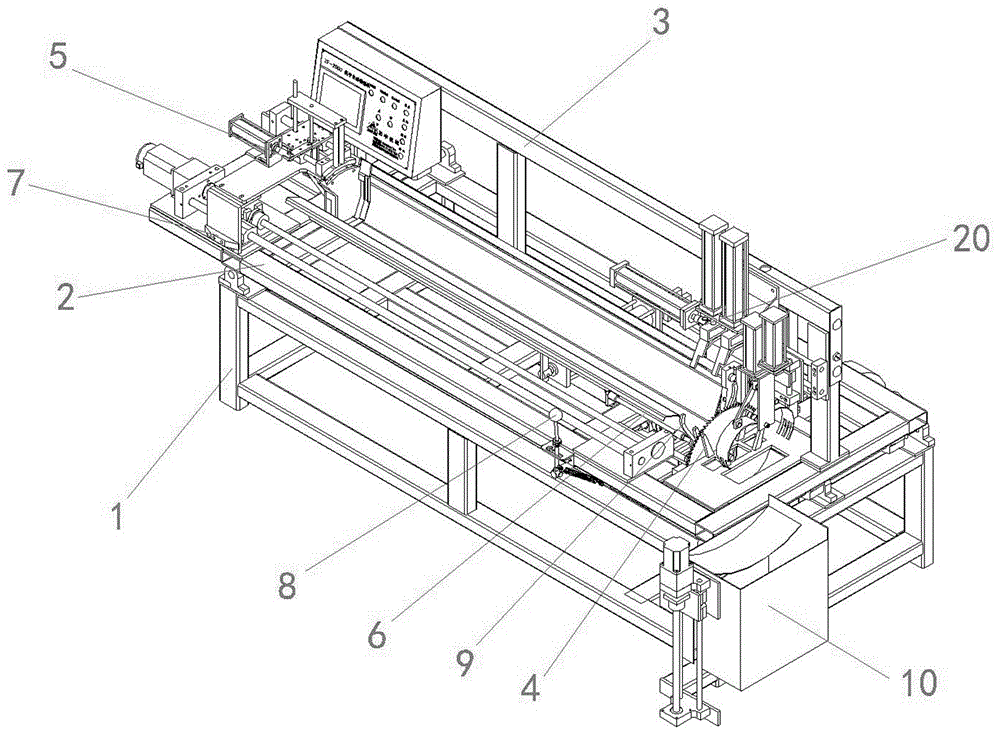

Multifunctional CNC precision sawing machine

A multi-functional, precision sawing machine technology, applied in sawing machines, metal sawing equipment, packaging, etc., can solve the problems of bar slipping, low efficiency, unfavorable packaging and finishing, etc., to reduce the process of finishing and aligning, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

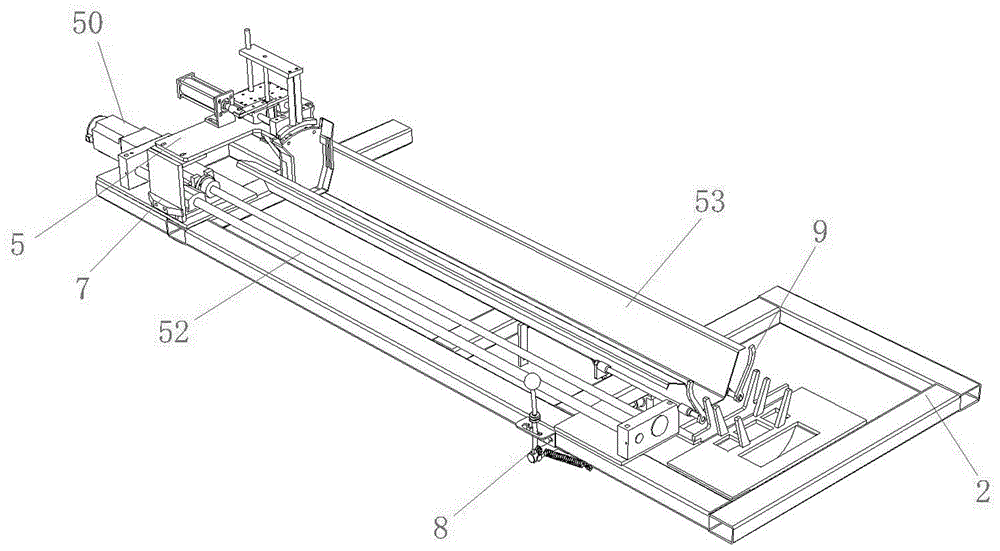

[0060] Embodiment two, such as Figure 11 The shown material storage channel 53 is fixed on the support chassis 1, and two columns are fixed on the side of the support chassis 1, and the material is pushed into the packing device 10 by the reciprocating movement of the cutting operation support, until all the materials in the channel are sawed. After finishing, the built-in baler of packing device 10 packs automatically, cancels two fixed columns on the side of support chassis 1, and sends the material in the gentle area of the channel into packing device 10 with a conveyor belt. A packaging device 10 is provided at the front end of the cutting device 4 , and a conveying device 20 is provided between the cutting device 4 and the packaging device 10 . The packing device 10 includes a packing power part arranged on the support chassis 1, a packing container arranged on the packing power part and a packing part connected with the packing power part and extending into the packin...

Embodiment 3

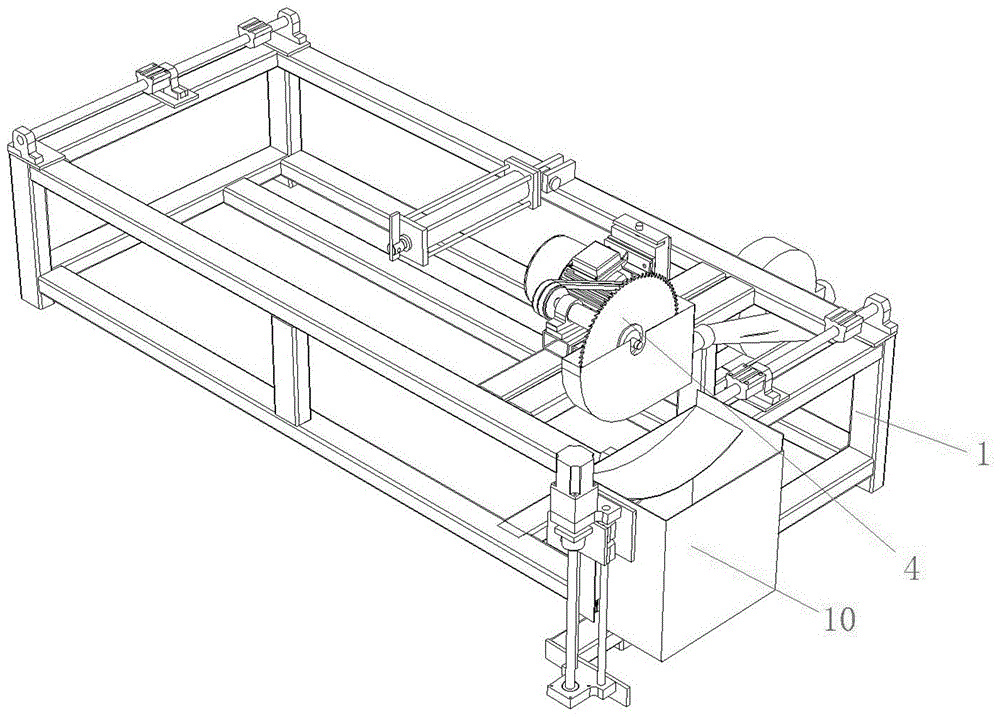

[0061] Embodiment three, such as Figure 10 The packaging device 10 shown includes a storage box, the storage box leaves a vertically movable surface and a laterally movable surface without setting the blocking part, and a slot is opened on the two storage boxes symmetrically provided with the blocking parts. An inner storage box is placed in the storage box, and only one surface of the inner storage box is not provided with a blocking portion, and an inner groove cooperating with the channel is also provided in the inner storage box. A platform is arranged in the groove, and a supporting elevating rod is arranged on the lower part of the platform. The supporting elevating rod extends out of the containing box, and the supporting elevating rod is fixed on the guide rail and connected with a machine that promotes the elevating of the supporting rod. When the material enters the storage box, the support lifting rod is lowered until the support lifting rod drops to the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com