Method for disposing unqualified product in polymeric composite material processing process

A composite material and processing technology, which is applied in the field of polymer composite material manufacturing, can solve problems such as product scrapping and product price reduction, and achieve the effect of reducing losses and reducing resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

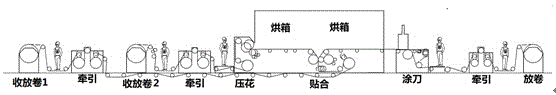

[0017] A method for disposing of unqualified products during the processing of polymer composite materials. A coating production line is used to separate the polymer material layer from the base fabric layer for products that have been determined to be unqualified products, and then separate the separated The polymer material layer and base fabric layer are recycled and reused.

[0018] A method for disposing of unqualified products during the processing of polymer composite materials. For polymer composite materials that are unqualified and meet the peel strength not greater than 2.0N / mm, a coating production line based on coating and bonding is used. The polymer-based coating layer is separated from the fabric layer, and then the separated polymer material layer and base fabric layer are recovered respectively.

[0019] On the basis of the above scheme, the material of the coating layer can be polyvinyl chloride, polyethylene, thermoplastic elastomer, etc.; the base fabric c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap