Insert moulding technology die, apparatus, method, and product

A technology of insert molding and mould, which is applied in the direction of coating, etc., can solve the problems of injection molding product approval, control the clamping position of the front mold and the rear mold, and difficult problems, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The accompanying drawings are given by way of illustration only. The figures are drawn schematically only and not to scale among the various parts. In particular, the spacing therein is shown exaggerated for clarity.

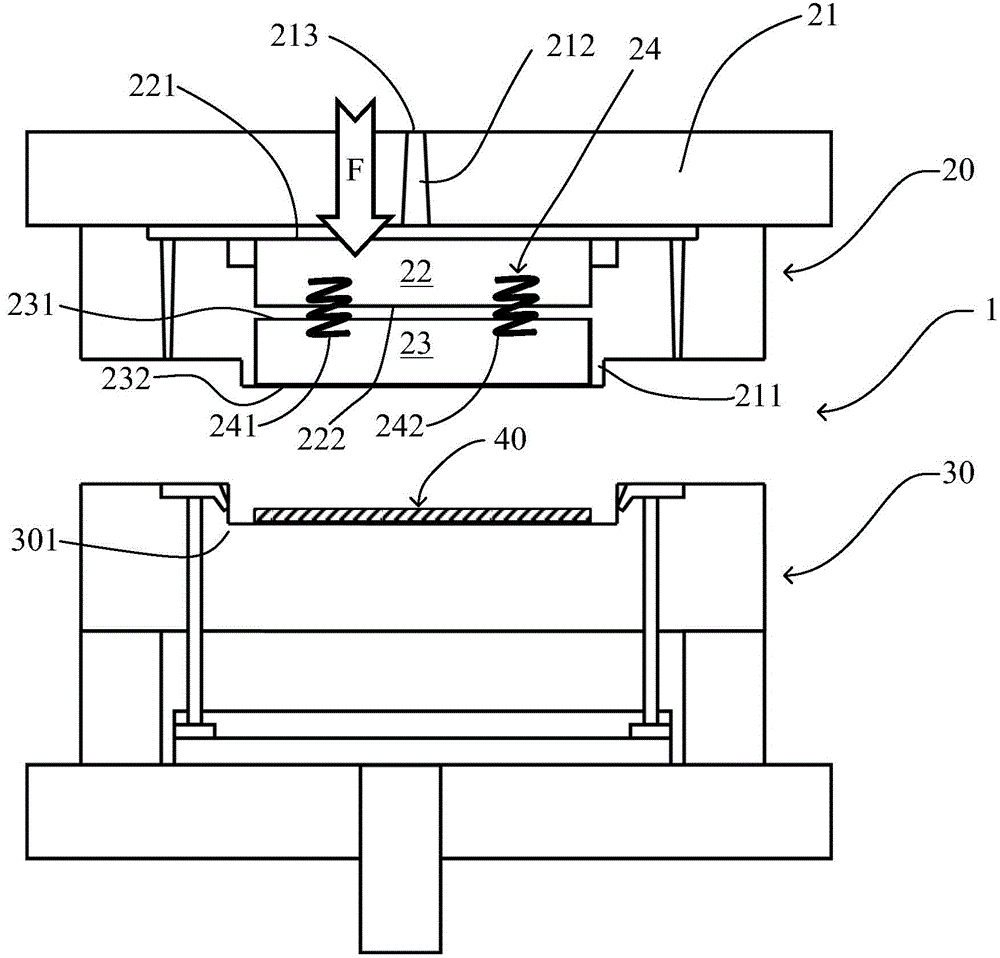

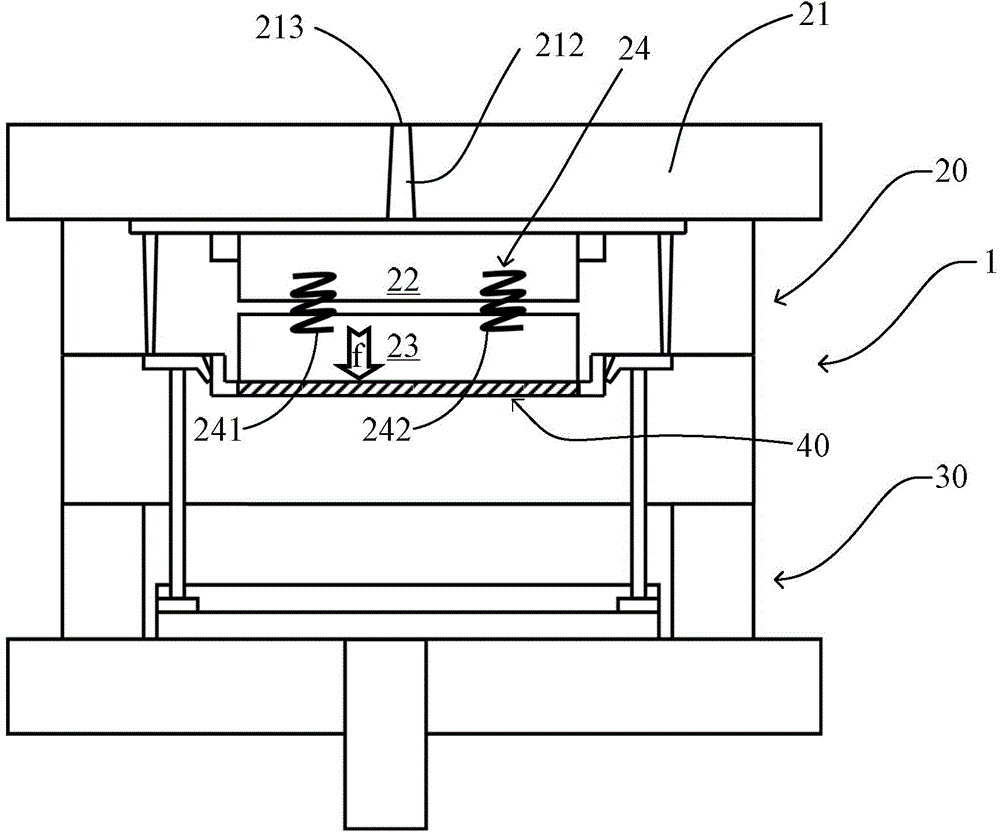

[0048] figure 1 A mold 1 for an insert molding process according to an embodiment of the present invention is shown in an open state.

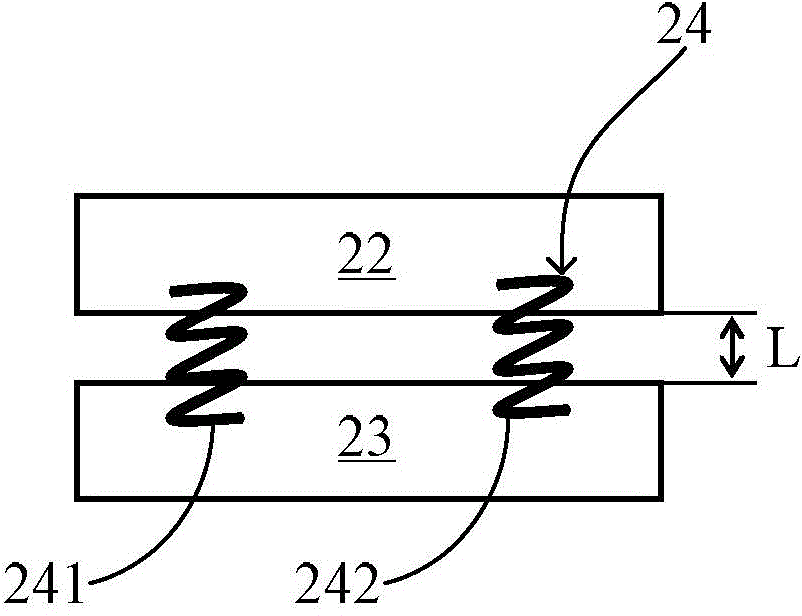

[0049] The mold 1 comprises a first mold part and a second mold part. In this embodiment, the front mold 20 and the rear mold 30 are the front mold 20 and the rear mold 30, respectively. The front mold 20 includes a front mold body 21 , a first movable insert 22 , a second movable insert 23 , and an elastic member 24 connecting the first movable insert 22 and the second movable insert 23 . Both the first movable insert 22 and the second movable insert 23 can translate in a direction toward the mold cavity and in a direction away from the mold cavity. In this embodiment, the elastic member 24 is composed of two compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com