Tubular capacitive deionization desalting device

A technology of capacitive deionization and desalination device, which is applied in separation methods, dispersed particle separation, special treatment targets, etc., can solve the problems of inconvenient disassembly and replacement, waste of cost, heavy quality, etc. The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

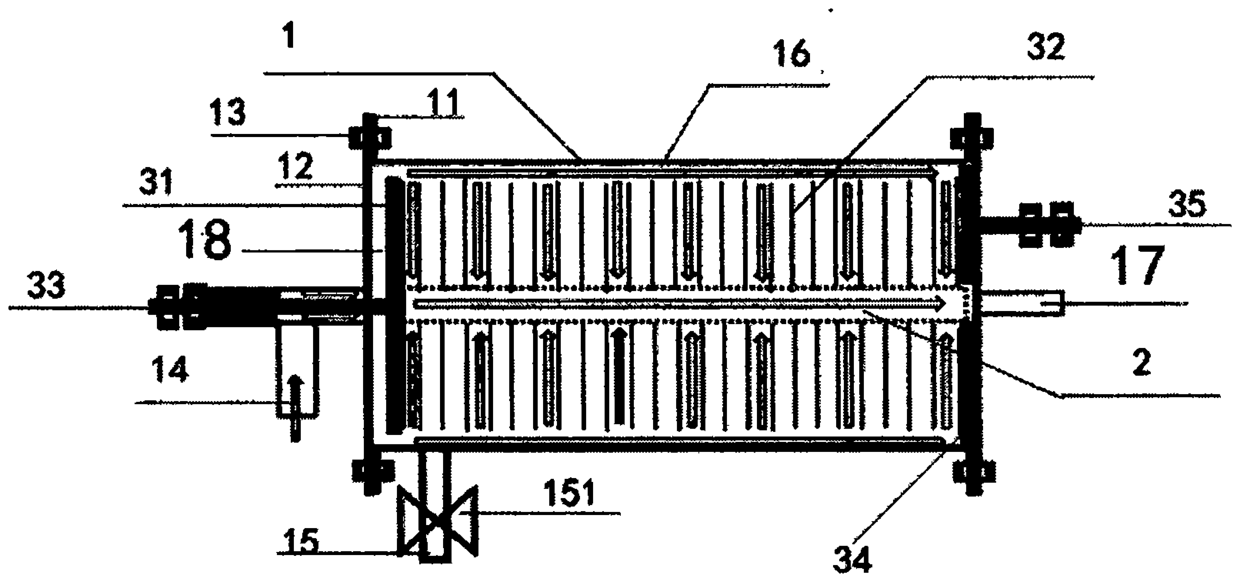

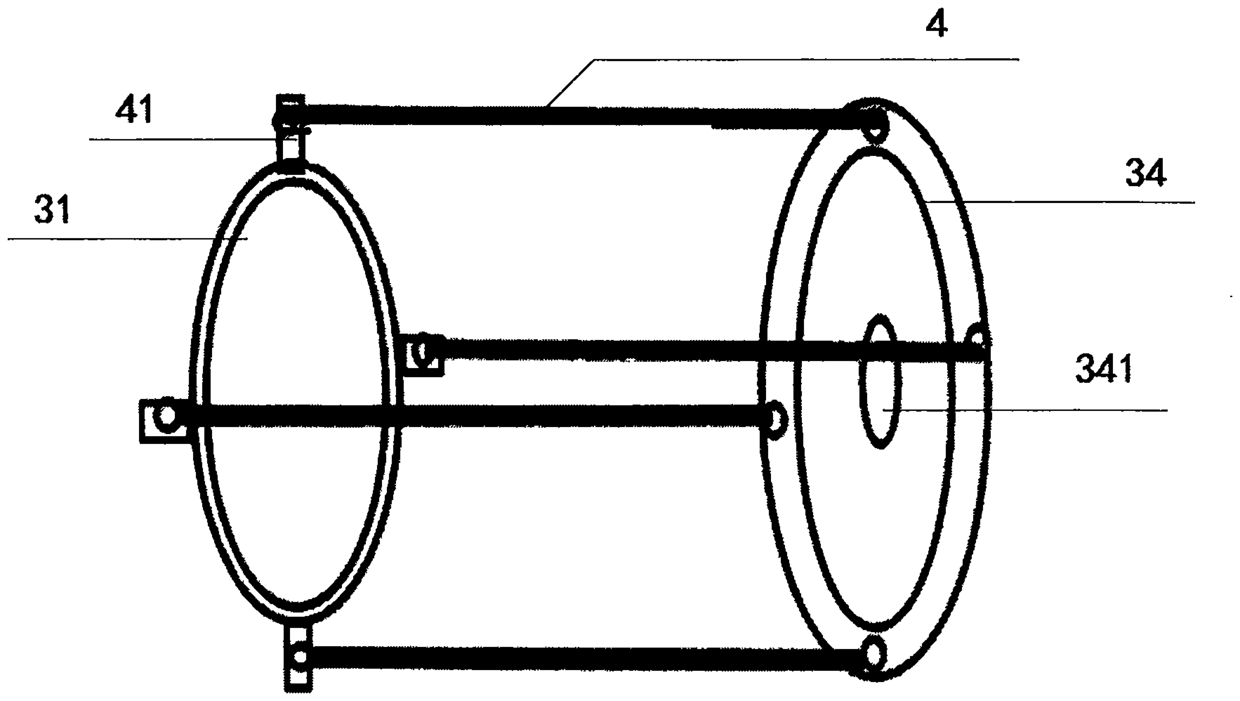

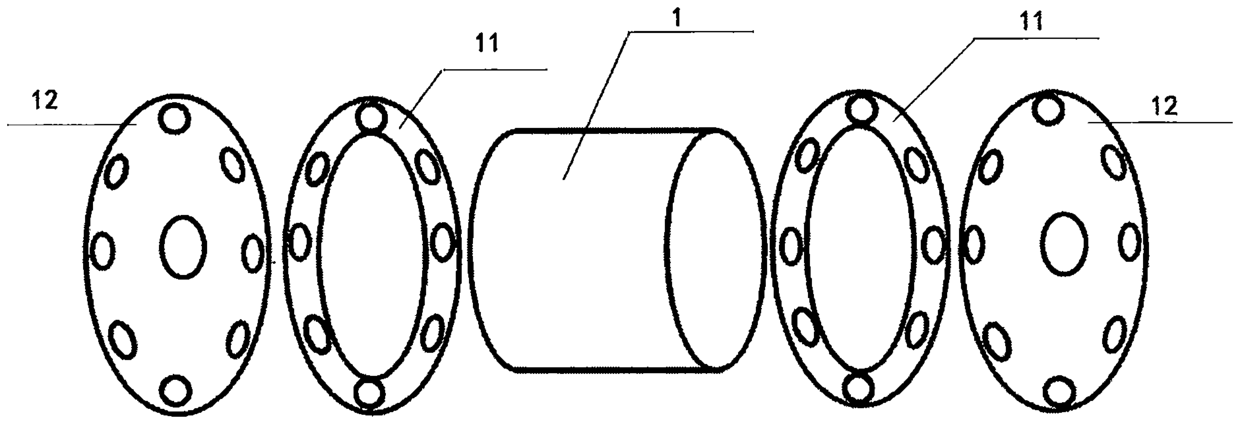

[0034] Combine below Figure 1 to Figure 3 , the present invention is further described:

[0035] A tubular capacitive deionization and desalination device, comprising a reactor main body 1, a water inlet 14 for sewage containing charged particles is provided at one end of the reactor main body 1, and a water outlet 17 is provided at the other end of the reactor main body 1. The water outlet 14 is provided with a first electrode end plate 31, a second electrode end plate 34 is provided at the water outlet 17, and a water distributor 2 is provided between the first electrode end plate 31 and the second electrode end plate 34. 2 The end connected to the first electrode end plate 31 is closed, the other end of the water distributor 2 passes through the second electrode end plate 34 and communicates with the water outlet 17, and the surface of the water distributor 2 is provided with a plurality of water inlet holes; A plurality of electrode sheets 32 arranged in parallel are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com