Pipeline same-stroke type construction method for ground source heat pump system

A ground-source heat pump, the same program technology, applied in the pipeline system, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve the problems of large water leakage, failure to reach the design value, failure of regional wells, etc., to prevent Side sliding, ensuring stability, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

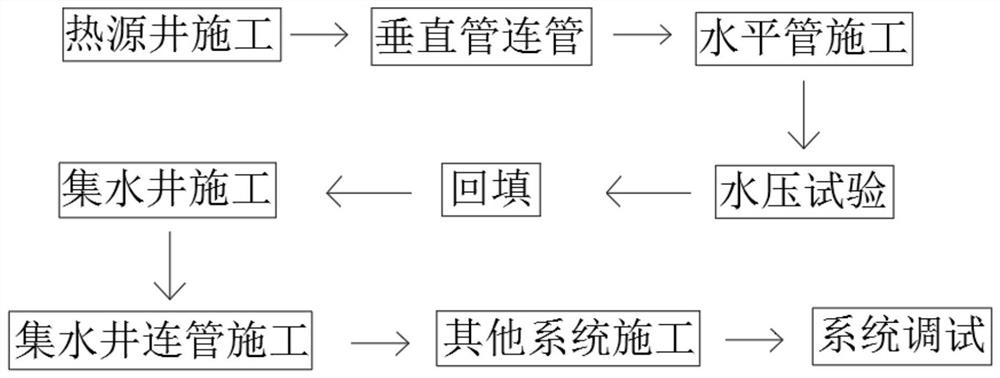

[0031]Seefigure 1, A ground source heat pump system pipeline same-type construction method, including the following steps:

[0032]Step 1, heat source well construction, heat source well construction consists of three steps:

[0033](7), check and ensure that the prefabricated buried tube actual length is not less than 122 meters, ensuring that the construction will meet the design requirements;

[0034](8) Determine the spacing of the buddu and verticality to ensure the verticality of the drilling;

[0035](9), inject the back puller into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com