Sealing device for jacking and rotating of printing plate cylinder

A sealing device and printing plate roller technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of affecting the sealing effect and poor ink blocking effect, and achieve the effect of good ink blocking and sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

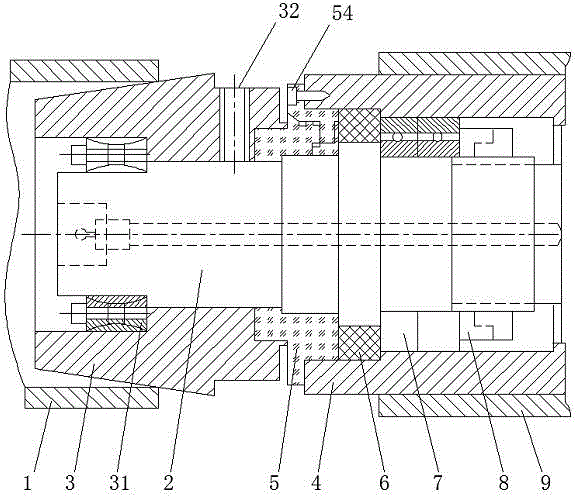

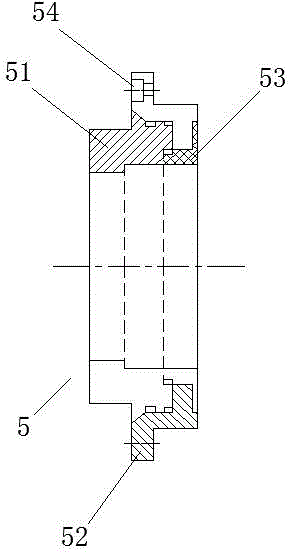

[0014] refer to figure 1 and figure 2 As shown, the sealing device for the tight rotation of the printing plate cylinder includes a mandrel 2 matching the specification of the printing plate cylinder 1, and the outside of the mandrel 2 is provided with a top tight head 3 and a moving sleeve 4. The top tight bulkhead 3 is integrated with the mandrel 2 through the expansion ring 31 and the support screw 32. The outer part of the moving sleeve 4 is provided with a ferrule 9. The top tight bulkhead 3 and the moving sleeve 4 are located between the core The outer surface of the shaft 2 is provided with an ink retaining assembly 5, and the ink retaining assembly 5 is composed of an ink retaining ring a51, an ink retaining ring b52 and an ink retaining ring c53, and the ink retaining ring b52 is connected with the moving sleeve through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com