Oil cup type pad printing machine ink filling structure

A technology of pad printing machine and oil cup, which is applied in the field of ink filling structure of pad printing machine, which can solve the problems of difficult cleaning of ink, uncontrollable ink outflow position of oil cup, air pollution, etc., and achieves easy cleaning or reuse , The effect of cleaning and environmental protection in the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

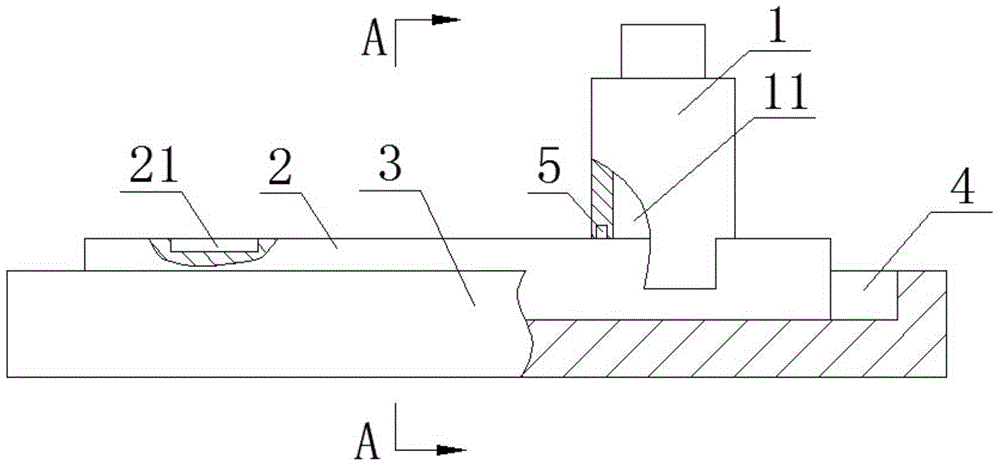

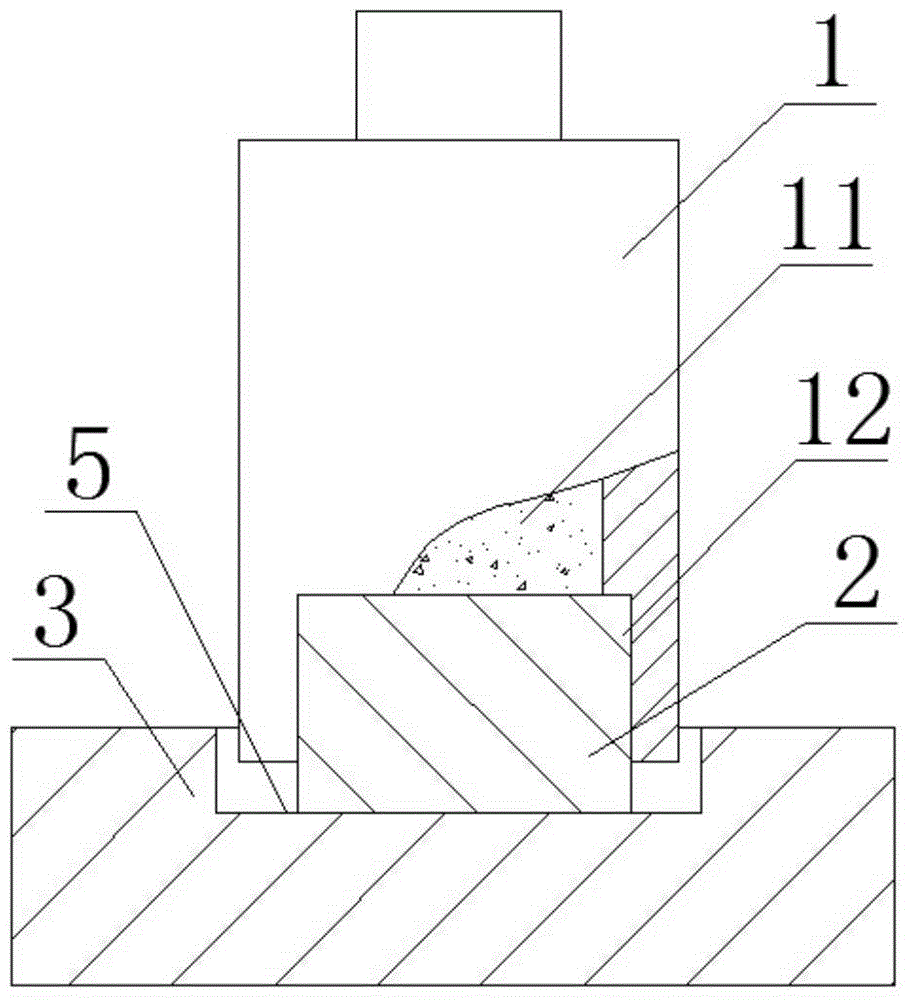

[0015] Such as figure 1 , figure 2 As shown, an oil cup type pad printing machine ink filling structure includes an oil cup 1 with an ink chamber 11 and a pad printing steel plate 2 with a concave pattern 21. There is pad printing ink in the ink chamber 11, and the middle of the lower end of the oil cup 1 There is a rectangular notch 12 that runs through the front and rear walls of the oil cup 1, so that the walls at the lower opening of the oil cup 1 have notches that are penetrated by a rectangular section. The width of the rectangular notch 12 is equal to the width of the pad printing steel plate 2, and the pad printing steel plate 2 fits In the rectangular notch 12 and seal the ink cavity 11, the oil cup 1 slides and fits on the pad printing steel plate 2 at the rectangular notch 12 on it; there is an ink leakage groove 3 under the pad pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com