Axial flow fan ventilation wall

An axial flow and fan technology, applied in mechanical equipment, non-variable pumps, machines/engines, etc., can solve problems such as inability to achieve airflow effects, shedding, disturbed airflow, etc., and achieve high efficiency and airflow in rated working conditions Stabilizes and prevents vortex shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

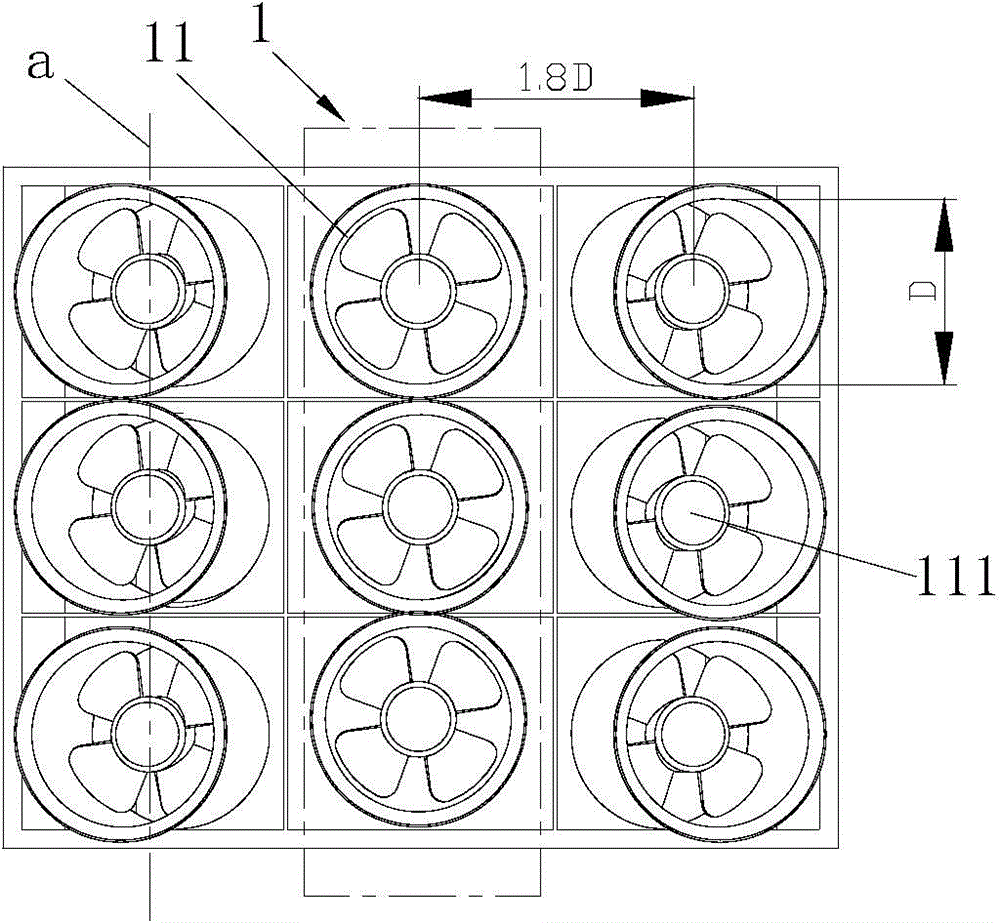

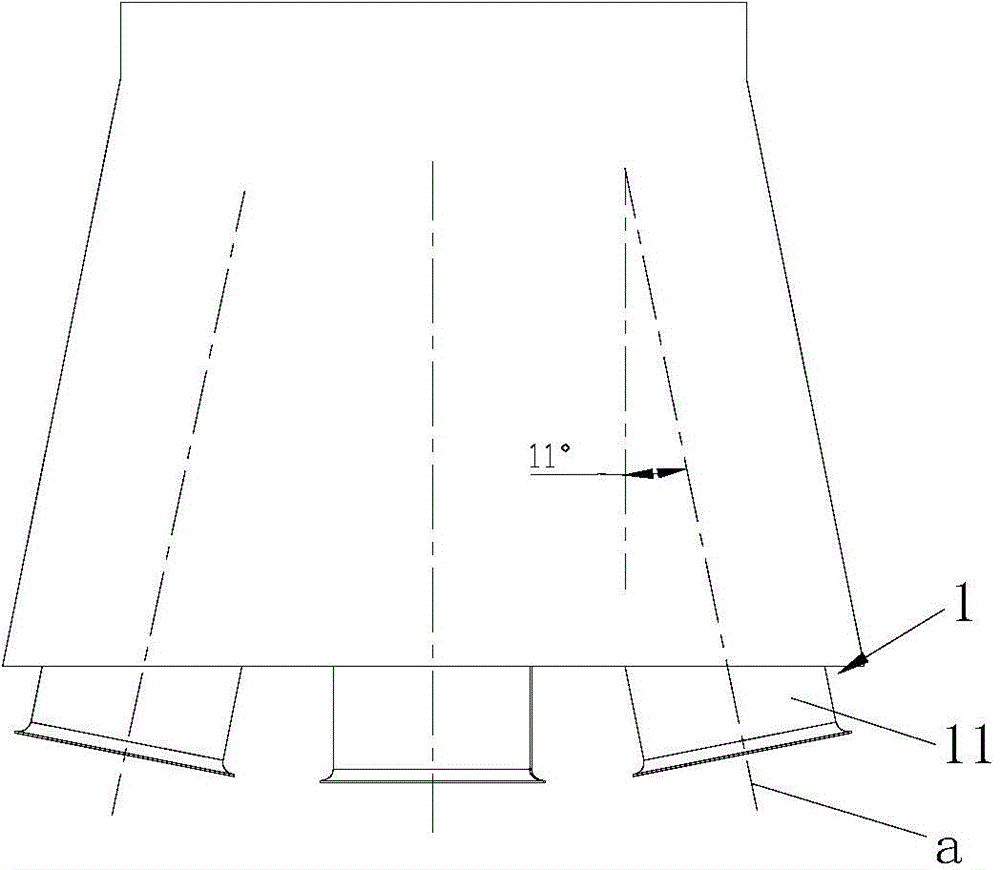

[0018] Embodiment one: if figure 1 , 2 As shown, the present embodiment includes three groups of fan units 1, each group of fan units 1 is composed of three axial flow fans 11 with a diameter of D, and the impeller shafts 111 of the axial flow fans 11 in the same fan group 1 are adjacent to each other. Arranged parallel to each other; the impeller shafts 111 in the same fan unit 1 are located on the same plane, which is named group base plane a; the group base planes a of two adjacent fan units 1 are set at an angle of 11°. In two adjacent fan groups 1, each axial flow fan in one fan group 1 corresponds to each axial flow fan in the other fan group 1 in sequence, and there is a one-to-one correspondence between two adjacent fan groups 1 The center distance of the axial fan 11 is 1.8D. (D is 80cm, the same below)

[0019] Through the CFX fluid dynamics simulation software, the flow rate of this embodiment is 103m 3 / h, when the total pressure is 804Pa, the best rated effici...

Embodiment 2

[0020] Embodiment 2: The only difference from Embodiment 1 is that the base surfaces a of two adjacent fan units 1 are set at an angle of 7°.

[0021] Through the CFX fluid dynamics simulation software, the flow rate of this embodiment is 103m 3 / h, when the total pressure is 823Pa, the best rated efficiency is 86%.

Embodiment 3

[0022] Embodiment 3: The only difference from Embodiment 1 is that the base surfaces a of two adjacent fan units 1 are set at an angle of 13°.

[0023] Through the CFX fluid dynamics simulation software, the flow rate of this embodiment is 103m 3 / h, when the total pressure is 833Pa, the best rated efficiency is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com