Lubrication structure of babbitt alloy sliding bearing bush for speed increasing machine

A babbitt, lubricating structure technology, applied in bearing components, shafts and bearings, bearing cooling, etc., can solve the problem of unsolved bearing temperature rise, low efficiency of speed increaser, etc., to reduce temperature and improve operating efficiency. , the effect of reducing running friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

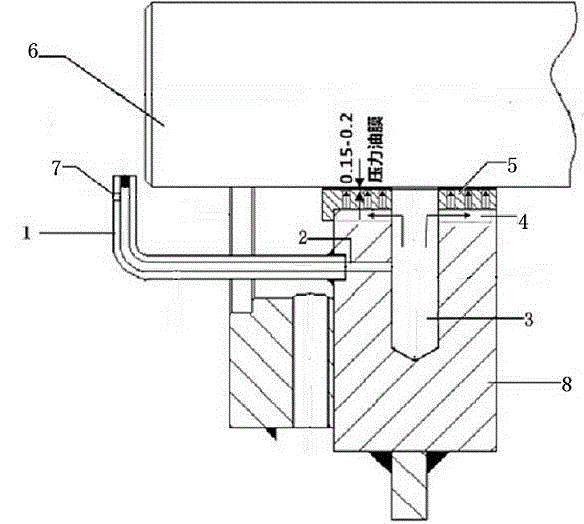

[0013] A babbitt alloy sliding bearing bush lubrication structure applied to a speed increaser, comprising a forced lubricating oil pipe 1, a through hole 2 of a speed increaser body, an oil line groove 3, an oil storage tank 4, and a babbitt alloy sliding bearing bush 5. The forced lubricating oil pipe 1 is a 90° elbow, one end is provided with an oil inlet 7, and the other end is connected to the through hole 2 of the speed increaser body. The through hole 2 of the speed increasing machine body crosses the speed increasing machine body 8, one end is connected with the forced lubricating oil pipe 1, and the other end is connected with the oil line groove 3. There are holes on the side of the oil line groove 3, which are respectively connected to the through hole 2 of the speed reducer body and the oil storage tank 4; the top of the oil storage tank 4 is provided with a pinhole-shaped small hole, and the upper part is a babbitt alloy sliding bearing pad; the babbitt alloy slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com