Submerged heating magnesium smelting furnace

A technology of immersion heating and immersion heater, applied in the field of magnesium smelting furnace and immersion heating magnesium smelting furnace, can solve the problems of low thermal efficiency, small smelting tonnage, low quality of magnesium or magnesium alloy, etc. The effect of melting rate and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

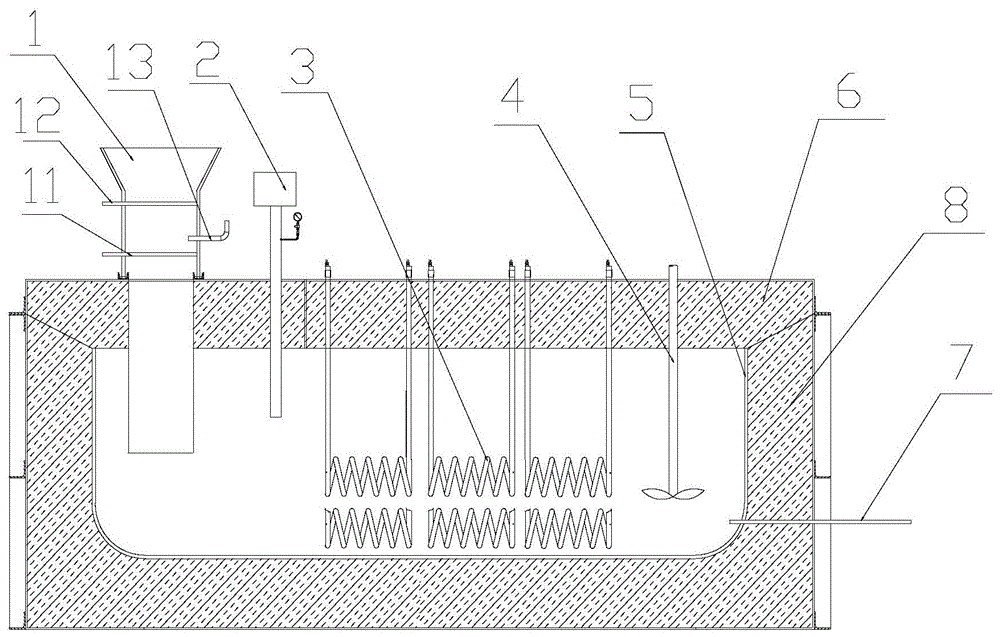

[0024] A submerged heating magnesium smelting furnace, such as figure 1 As shown, it includes a furnace shell 8, a separate furnace cover 6, a melting crucible 5, a feeding device 1, a protective gas input device 2, an immersion heater 3 and a discharge conveying device 7, and the melting crucible 5 is embedded in the furnace shell 8, The separate furnace cover 6 is covered above the furnace shell 8, the feeding device 1, the circulation pump 4 and the protective gas input device 2 are all fixed on the separate furnace cover 6, and the immersion heater 3 and the separate furnace cover 6 have a The disassembly method is fixed connection. When the separate furnace cover 6 is covered on the furnace shell 8, there is no gap between the separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com