Oil consumption monitoring intelligent terminal of engineering machinery vehicle

A vehicle fuel consumption and intelligent terminal technology, which is applied in measuring devices, instruments, and relative volumetric flow measurement, etc., can solve the problems of difficult management and inability to monitor fuel consumption in real time, and achieve the goal of improving measurement accuracy, promoting energy saving and consumption reduction, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

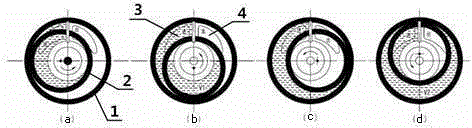

[0008] As shown in the figure, the present invention discloses an intelligent terminal for monitoring fuel consumption of construction machinery vehicles, including: a flow sensor 1 and a piston 2 arranged inside the flow sensor 1, and an inlet port 3 and a An outlet port 4; when the liquid to be measured enters the inner cavity of the flow sensor 1 from the inlet port 3, a pressure difference will be formed between the inlet port 3 and the outlet port 4, forcing the piston 2 from the inlet port 3 to the outlet port 4; as the liquid to be measured continues to flow in, the piston 2 continues to rotate from the inlet end 3 to the outlet end 4, forming a closed crescent-shaped cavity V1; under the action of the pressure difference, the piston 2 continues to rotate Rotate, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com