Feather defect detection system and method

A defect detection and detection method technology, which is applied in the field of feather defect detection system, can solve the problems of large differences in measurement and detection results, and the inability to complete the camber of feather shafts, so as to improve detection efficiency and reduce complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

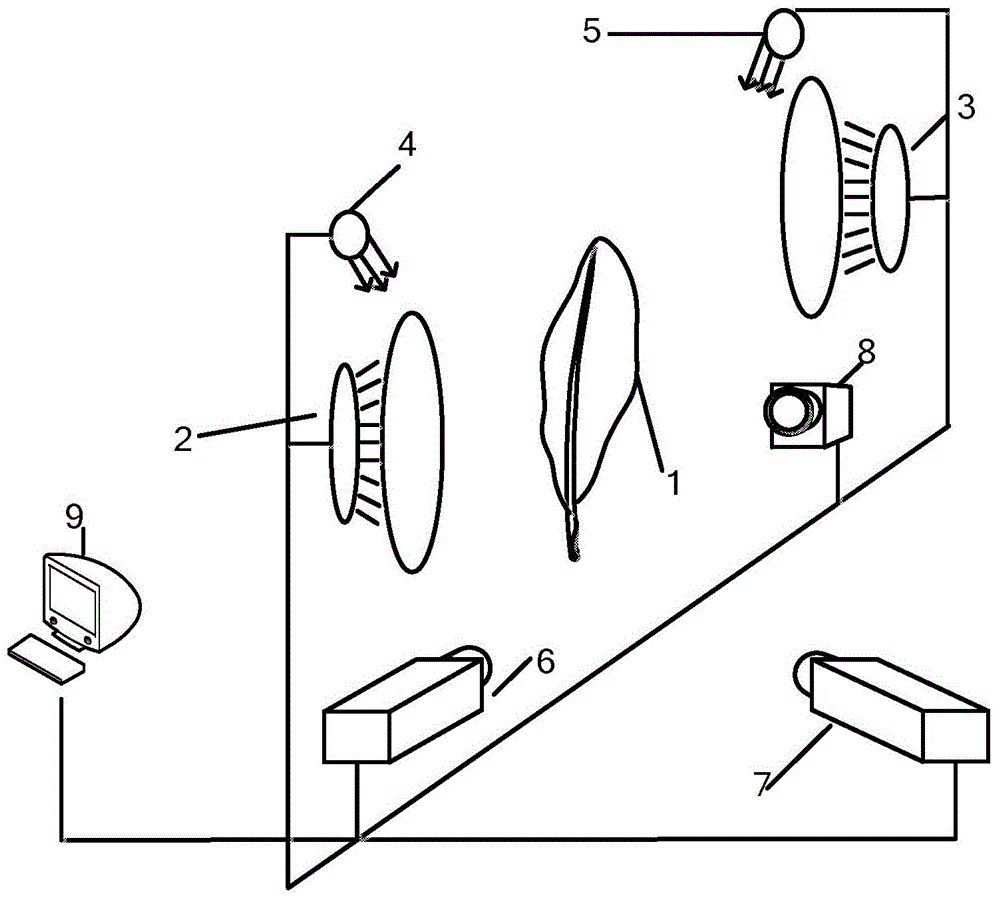

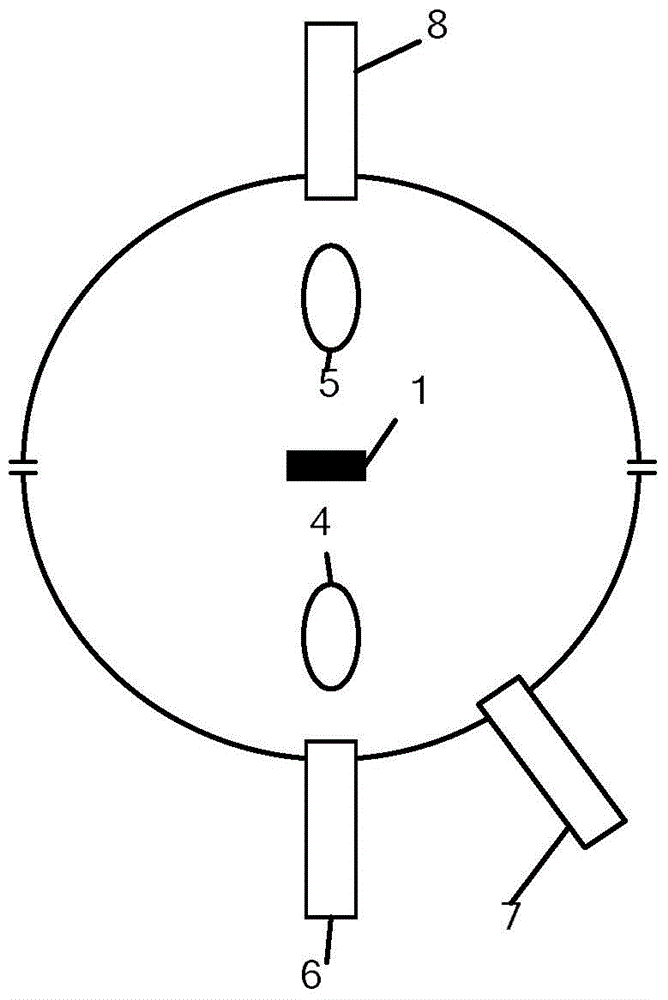

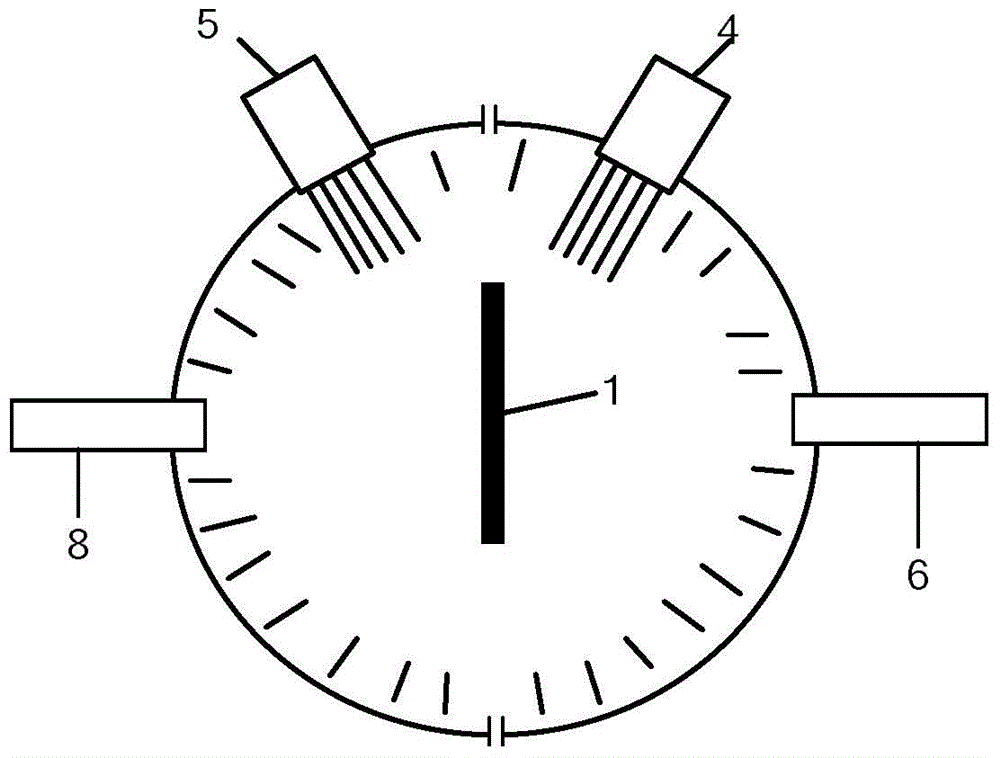

[0037] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0038] Such as figure 1 As shown, a feather defect detection system is characterized in that it includes a light source module, a processing module 9, and a camera module; the light source module includes a front uniform light source 2, a back uniform light source 3, a front low-angle direct light source 4, a A low-angle direct light source 5, the camera module includes a first camera 6, a second camera 7, and a third camera 8; wherein,

[0039] The front uniform light source is set on the front of the feather 1, and is used to provide uniform illumination when collecting the front image of the feather;

[0040] The back uniform light source is set on the back of the feather to provide uniform illumination when collecting the image of the back of the feather;

[0041] The front uniform light source and the back uniform light source provide ideal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com