Ejector piece type double-sided optical disk box

A technology of optical disc case and shrapnel, which is applied in recording information storage, instruments, etc., can solve the problems of high cost, unable to grab double-sided optical disc, complicated operation of reading and writing disc, etc., to protect from damage and facilitate reading and writing of disc. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

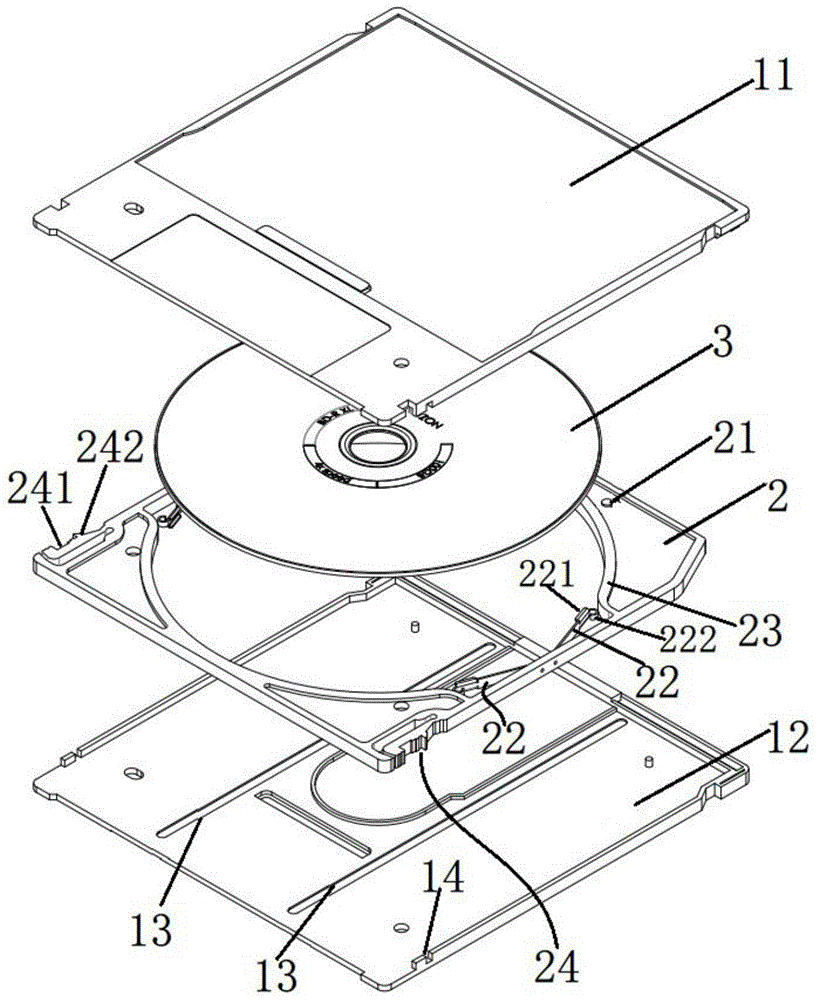

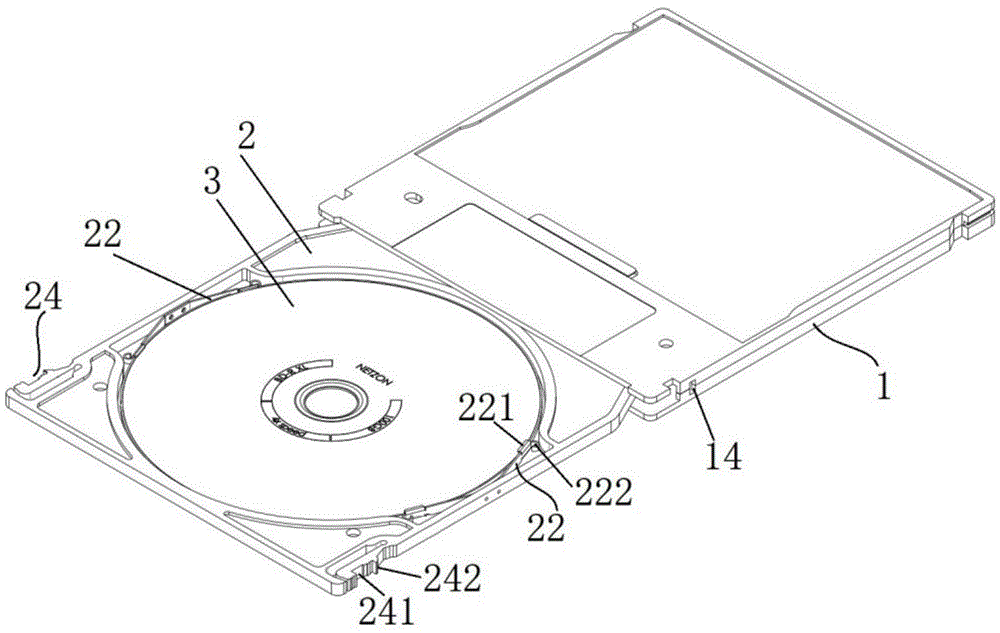

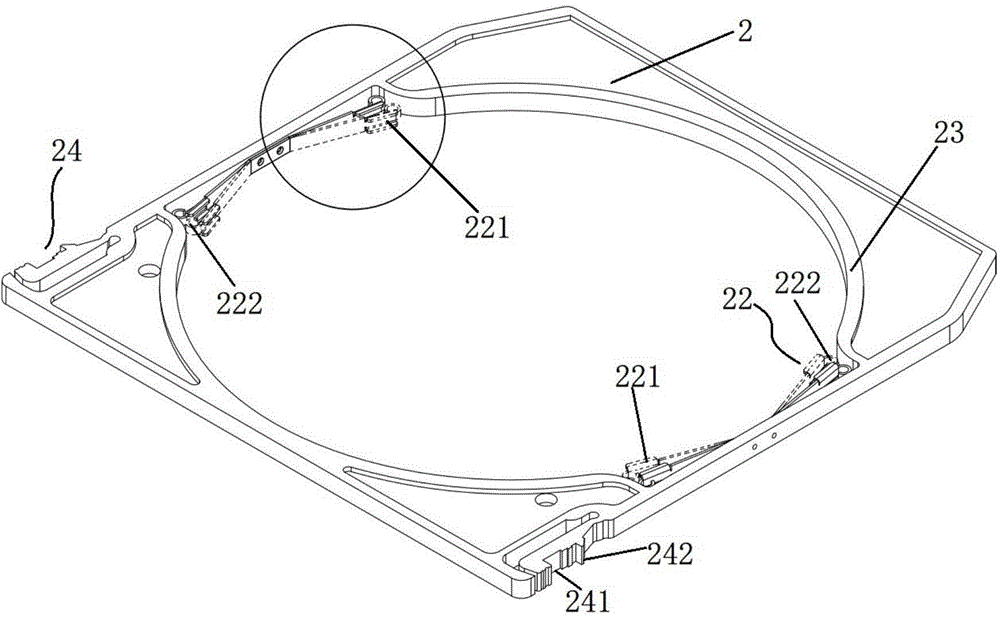

[0028] Example: figure 1 It is a schematic exploded view of the structure of the shrapnel-type double-sided disc case provided by the embodiment of the present invention, figure 2 The overall schematic diagram of the spring-type double-sided disc case provided by the embodiment of the present invention, it can be clearly seen from the figure that the spring-type double-sided disc case provided by this embodiment includes a case body 1 with an opening at the front end and a case body 1 located in the case. The disc tray 2 in the body 1, the middle part of the disc tray 2 is provided with a hollow circular coil 23, and the circular coil 23 is provided with several coil gaps extending to the inner wall of the disc tray 2, A strip-shaped shrapnel 22 is provided at the notch of the coil, one end of the shrapnel 22 is fixedly connected to the inner wall of the disc tray 2 at the notch of the coil, and the other movable end is close to the notch of the coil and has a A slot 221, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap