Electric-car storage-battery anti-shock crashproof structure

A technology for batteries and electric vehicles, applied to batteries, structural parts, battery pack components, etc., can solve the problems of extrusion damage of battery pole groups, reduce the failure rate of battery packs, and failure of battery packs, so as to solve the problems of extrusion damage. , Vibration and impact force reduction, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

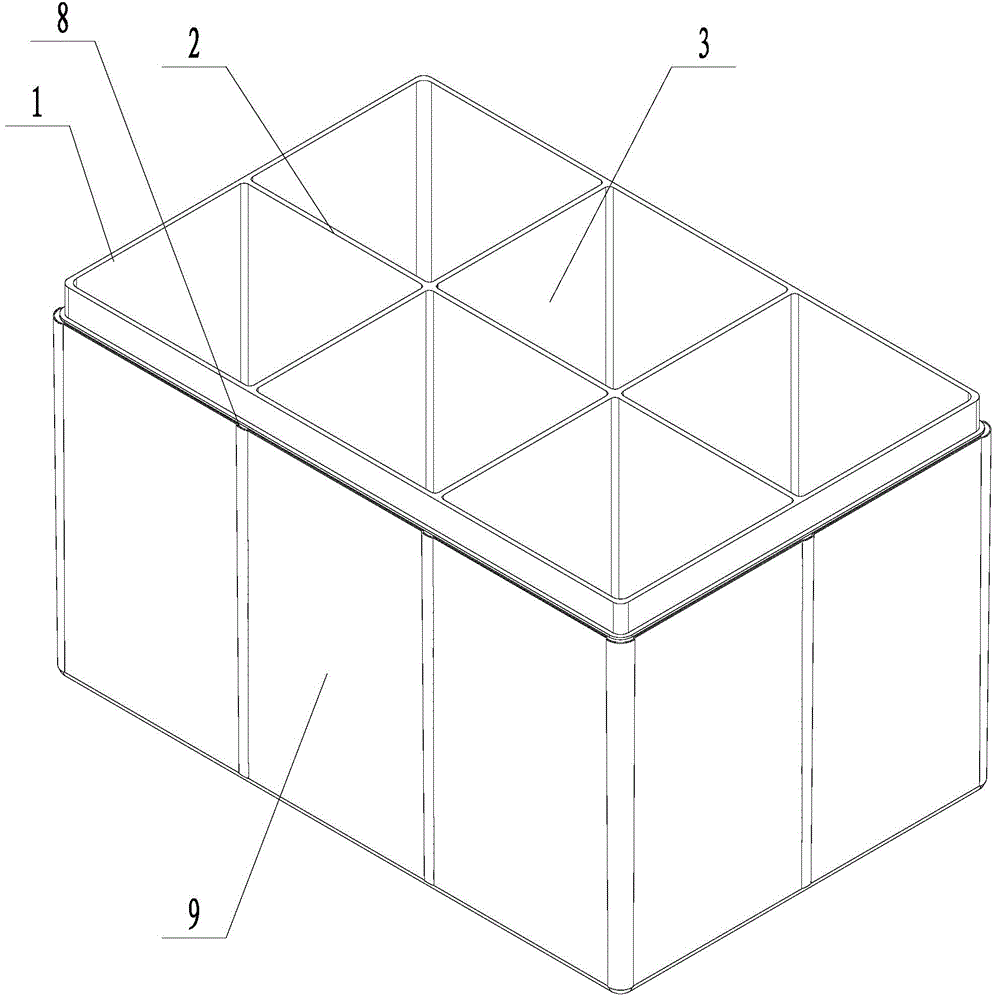

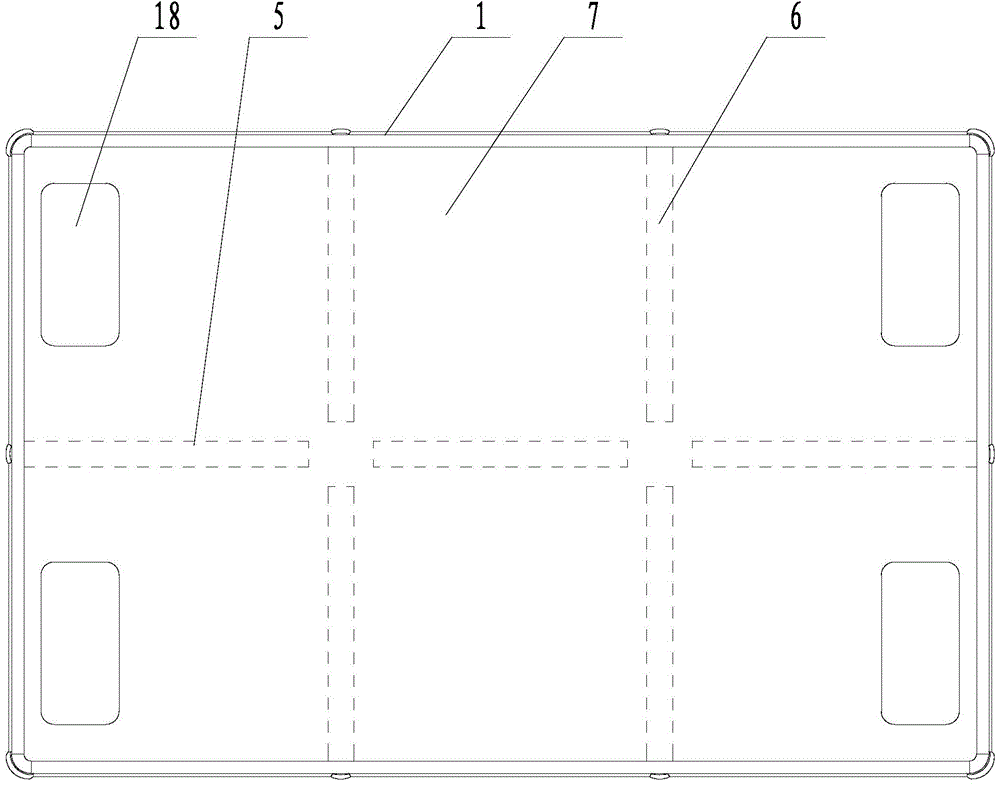

[0024] Embodiment 1: An anti-shock and anti-collision structure of an electric vehicle battery (see attached figure 1 , attached figure 2 ), including a battery case 1 with a rectangular parallelepiped structure. A separator 2 is arranged inside the battery case to divide the battery case into several battery unit installation slots 3. Three partitions divide the battery case into six battery unit installation slots. One longer partition is arranged horizontally, two shorter partitions are arranged vertically, and three partitions are arranged crosswise to form two "ten"-shaped structures, and the partitions are integrally formed with the battery case. A battery electrode group unit 4 is installed in each battery unit installation groove. The inner bottom surface of the battery housing is provided with a shockproof support pad. The outer bottom surface of the battery case is provided with transverse ribs 5 and longitudinal ribs 6 , and the outer bottom surface of the batter...

Embodiment 2

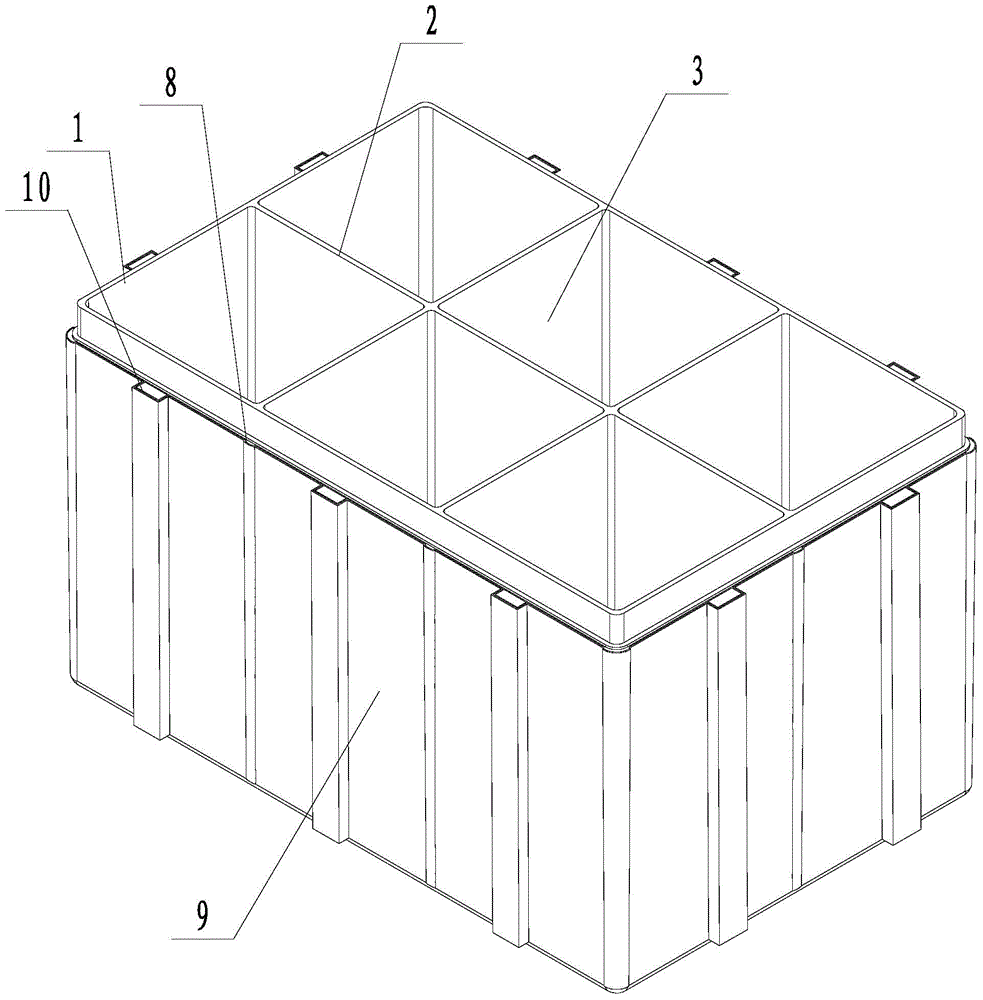

[0026] Embodiment 2: An anti-shock and anti-collision structure of an electric vehicle battery (see attached Figure 3-6), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, there are several vertically arranged collision energy-absorbing grooves 10 on the outer walls around the battery case, and the collision energy-absorbing grooves have a "concave"-shaped structure And it protrudes from the outer wall of the battery case, and the crash pad covers the crash energy-absorbing groove inside. Three collision energy-absorbing grooves are arranged on both sides of the battery case in the length direction, and two collision energy-absorbing grooves are arranged on both sides of the battery casing in the width direction. , longitudinal ribs, and reinforced support feet are integrally formed with the battery case. The impact energy-absorbing groove of the "concave" structure has a strong ability to absorb impact force, which further pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com