Processing data obtained by operating a liquid treatment system

A liquid treatment and liquid technology, applied in the direction of water treatment parameter control, control/manipulation system, filtration treatment, etc., can solve the problems of incorrect hardness value, water softening device not conforming to the ideal model, not taking into account, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

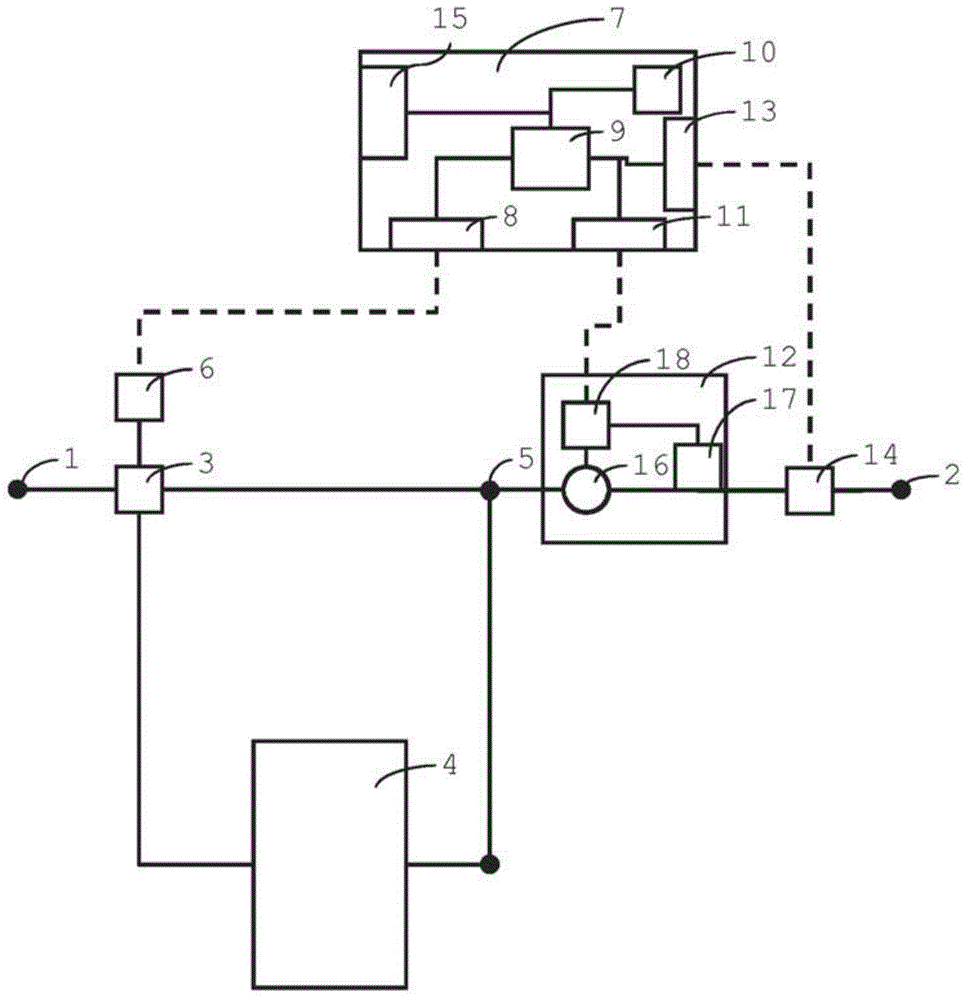

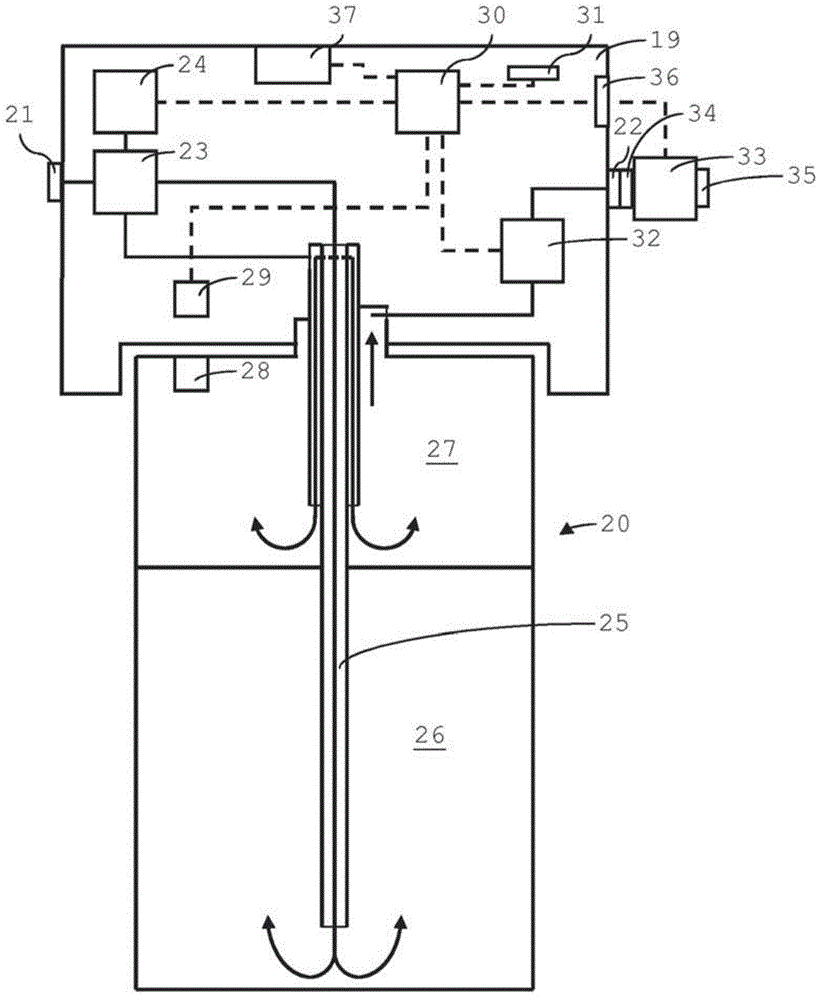

[0112] As an example of a liquid handling system, a system for softening water ( figure 1 ) includes an inlet 1 for connection to a source of untreated water. The water source may be, for example, a tap water source. The system comprises an outlet 2 for connection to an appliance (not shown) or a conduit leading to the appliance to supply the appliance with water of a suitable hardness level. The system can of course be configured to supply water to more than one appliance. First and second fluid paths pass through the system between the inlet 1 and the outlet 2 .

[0113] Untreated water entering the system through the inlet 1 is directed to a variable ratio flow divider 3 where the first and second fluid paths diverge. The first fluid path passes through a liquid treatment component 4 configured to remove to some extent minerals contributing to temporary hardness or carbonate hardness from water passing through it.

[0114] Said liquid treatment unit 4 comprises a bed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com