Determination of a conversion factor relating the conductivity and the hardness of water

A concentration and measurement technology, used in water hardness testing, water testing, descaling and water softening, etc., can solve problems such as inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

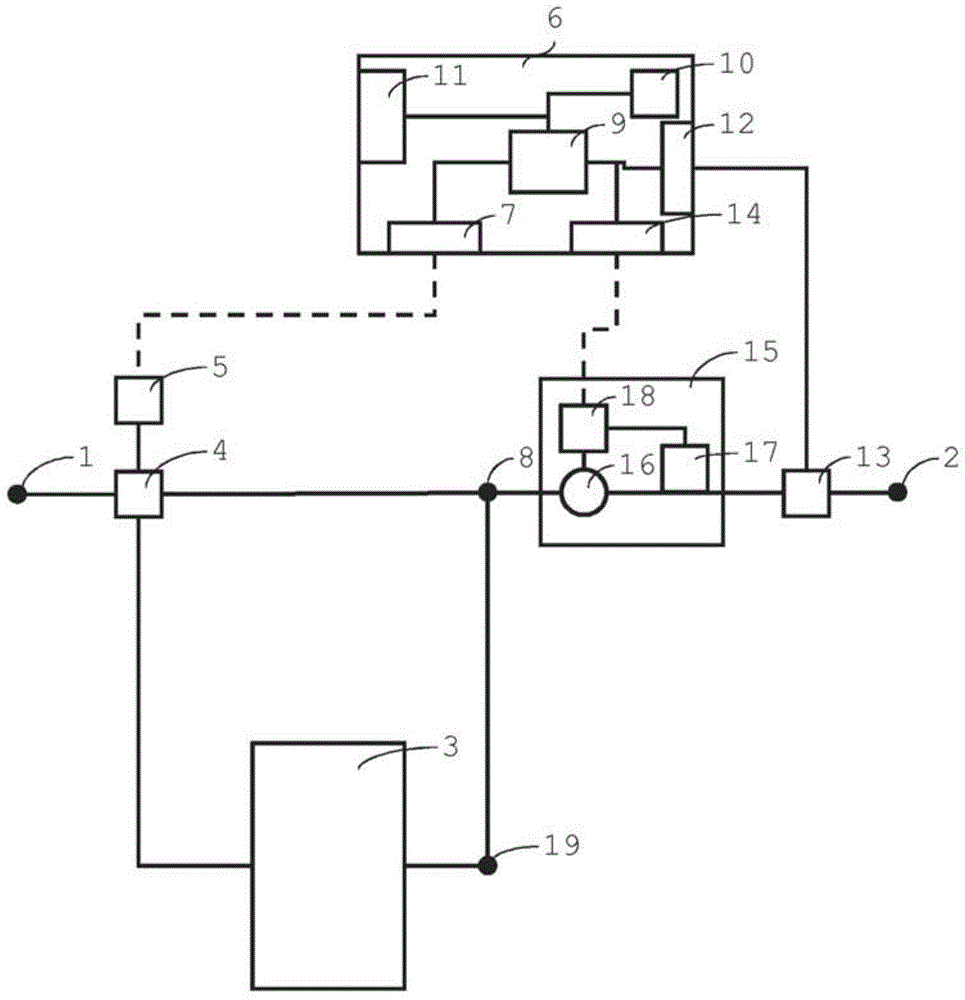

[0068] The example of a liquid treatment system for softening water will be used below. The apparatus is equally applicable to the treatment of other types of liquids, and the methods discussed below for determining the measure of hardness can also be used to determine components that may be removed by liquid treatment components of liquid treatment equipment for handling such other liquids. points of concentration.

[0069] pass figure 1 The example shown includes an inlet 1 for receiving untreated water and an outlet 2 for providing water with a desired level of temporary hardness. The inlet 1 may be connected to a source of untreated water, in particular a tap water source. The outlet 2 may be connected to an appliance such as a steamer, a dishwasher or an appliance for preparing beverages, eg a coffee machine. The fluid treatment arrangement comprises a fluid treatment device 3 configured to remove, at least to some extent, the temporary hardness of water passing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com