Pre-grading thickener

A concentrator and cyclone classification technology, applied in the field of concentrators, can solve the problems of increasing the sedimentation area of ore pulp, increasing the sedimentation efficiency of particles, reducing the sedimentation distance of particles, etc., and achieves the effect of reducing mutual interference, compact structure and optimized distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

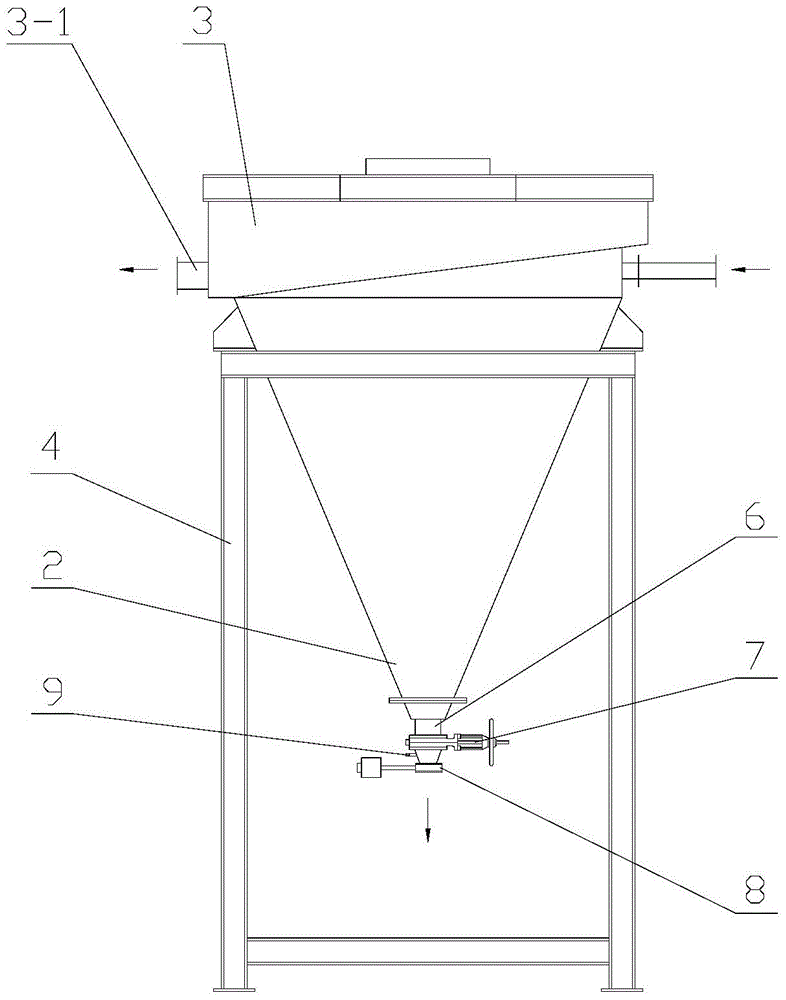

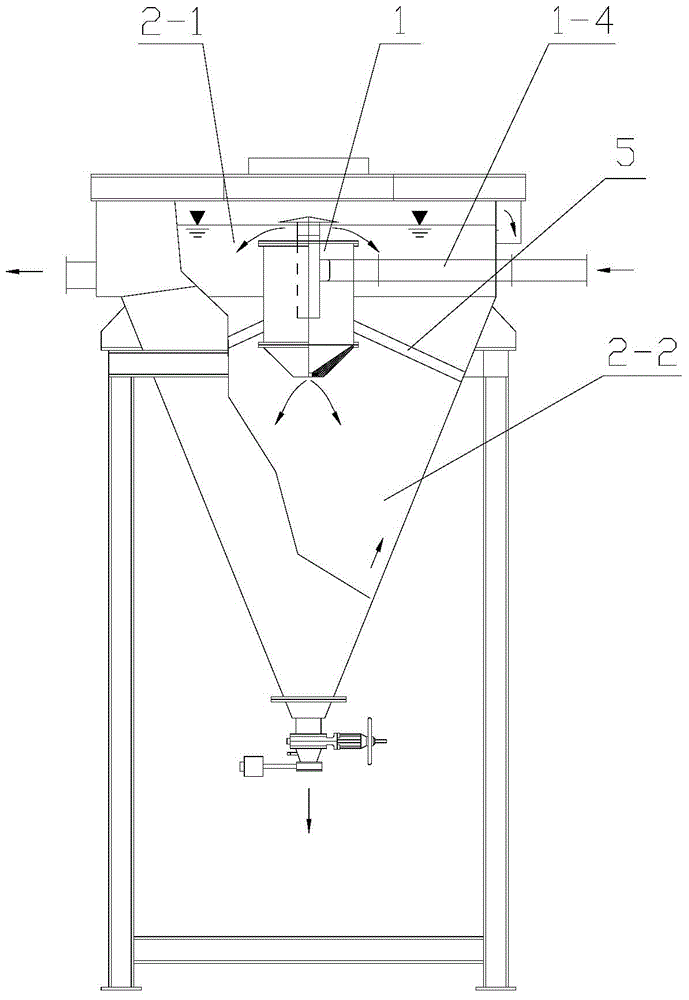

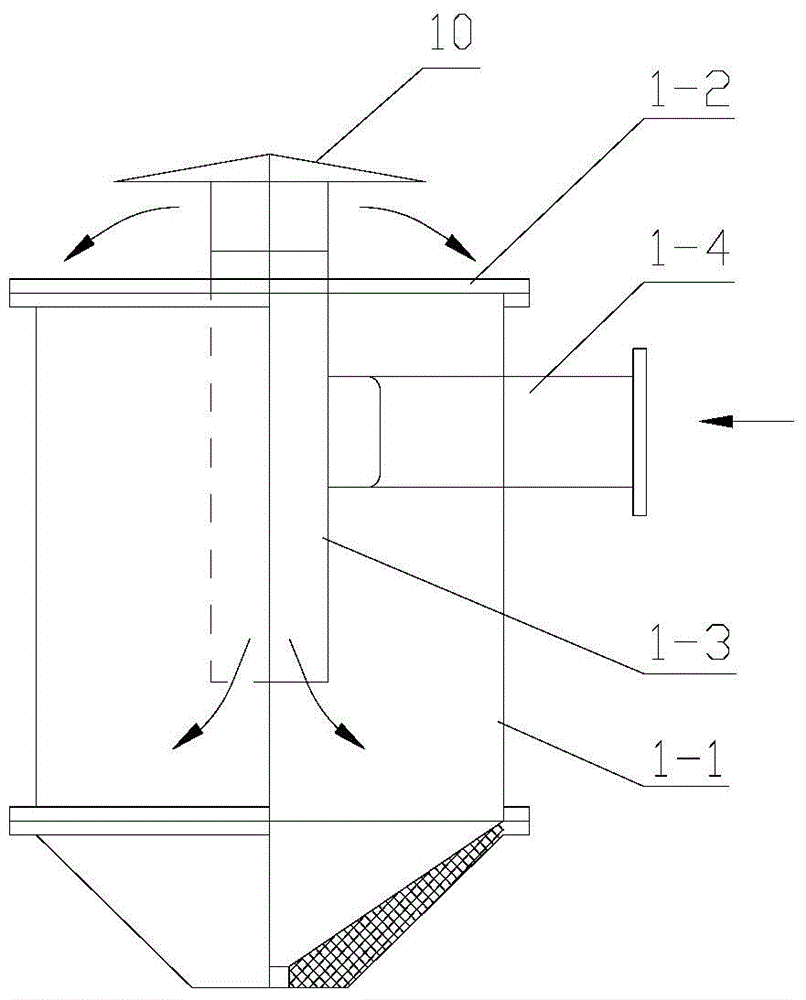

[0033] Please refer to figure 1 , figure 2 , figure 1 It is a structural schematic diagram of a specific embodiment of the pre-grading concentrator provided by the present invention; figure 2 for figure 1 partial sectional view.

[0034] In a specific embodiment, the pre-grading concentrator provided by the present invention is mainly composed of a cyclone classifying cone 1 , a tank body 2 , an overflow tank 3 , and a frame 4 .

[0035] The interior of the tank body 2 is divided into an upper concentration zone 2-1 and a lower concentration zone 2-2 by a partition, wherein the upper concentration zone 2-1 is cylindrical (or cube-shaped), and the lower concentration zone 2-2 is an inverted cone , is an inverted conical or inv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap