A method and device for removing iron

A fluid and channel technology, applied in the field of fluid iron removal, can solve the problems of fast fluid flow, loss, and influence on fluid flow, and achieve the effect of high operational reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

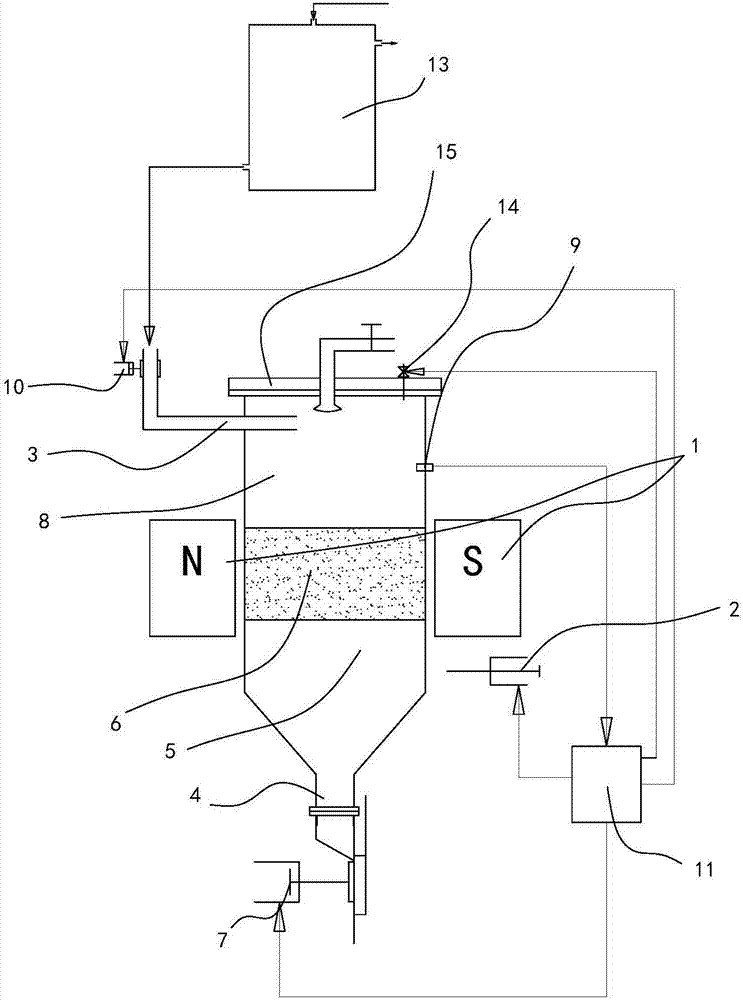

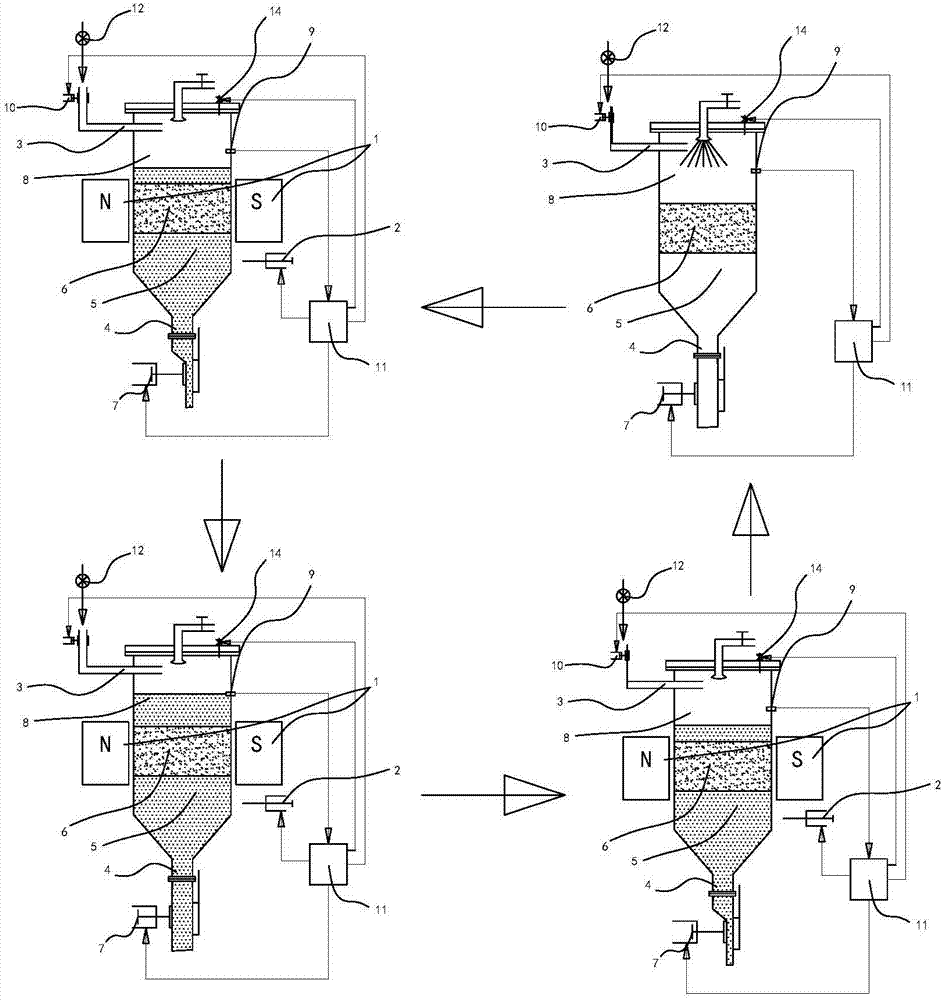

[0012] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0013] Such as figure 1 As shown, the present invention includes a magnetic field 1 composed of permanent magnets or electromagnets at the north and south poles, a passage 5 with a fluid inlet 3 at the top of the magnetic field 1 driven by a power 2, a passage 5 with a fluid outlet 4 at the bottom, and a passage 5 arranged in the passage 5. Soft magnetic medium 6. The power on / off valve 7 set on the fluid outlet 4 (the technology of patent 2012104899737 can be adopted), the upper part of the channel is closed, and the opening degree of the power on / off valve 7 when fully opened makes the fluid level high When going out above the soft magnetic medium in the channel, the amount of outflow is consistent with the amount of fluid entering the channel, and a liquid level detector 9 is set above the soft magnetic medium 6 in the channel 5 .

[0014] The fluid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com